Scraper structure and glue application method

A squeegee and squeegee technology, used in coatings, devices for applying liquid to surfaces, etc., can solve the problems of high price of thermally conductive gaskets, uneven thickness of thermally conductive adhesives, and too many fillers for high thermally conductive glues, reducing squeegeeing. The effect of uneven thickness, improving the convenience of the production process and improving the printing success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

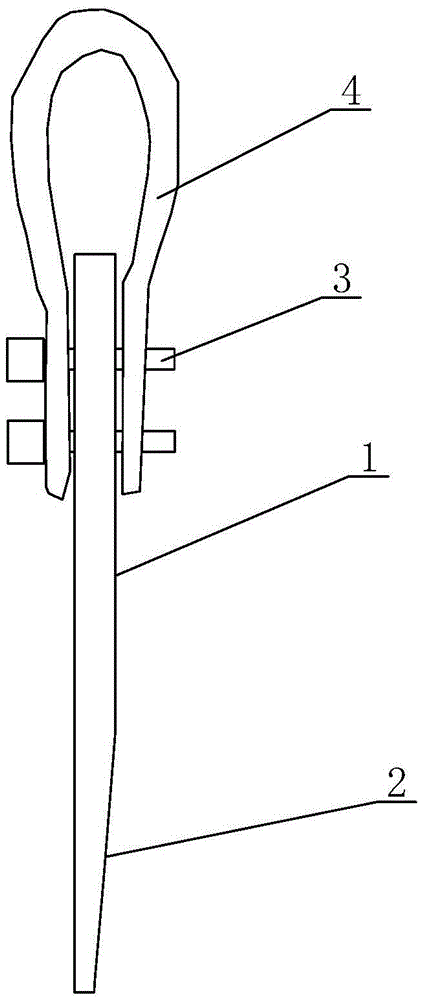

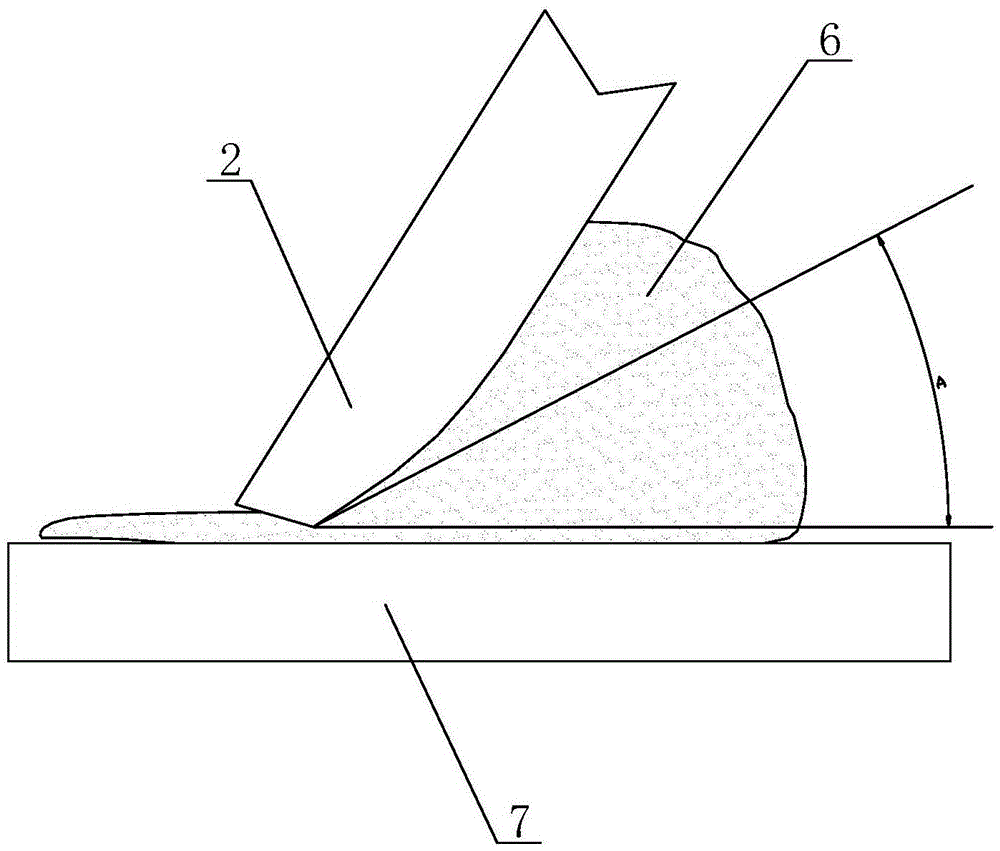

[0025] see Figure 1 to Figure 3 As shown, in this embodiment, a scraper structure is made of metal steel plate or hard plastic, including a blade body 1 and a blade head 2 with an integral structure, and one end of the blade body 1 is provided with a fastening handle 4 through a connecting screw 3, The other end is provided with a cutter head 2, the length of the cutter head is 1-4mm, and the thickness is 0.2-1mm. The squeegee surface of the cutter head 2 is coated with a water-repellent coating, and the water-repellent coating is nickel-plated to reduce wake adhesion and improve glue detachment performance, reduce scraper pollution and cleaning, and improve production efficiency.

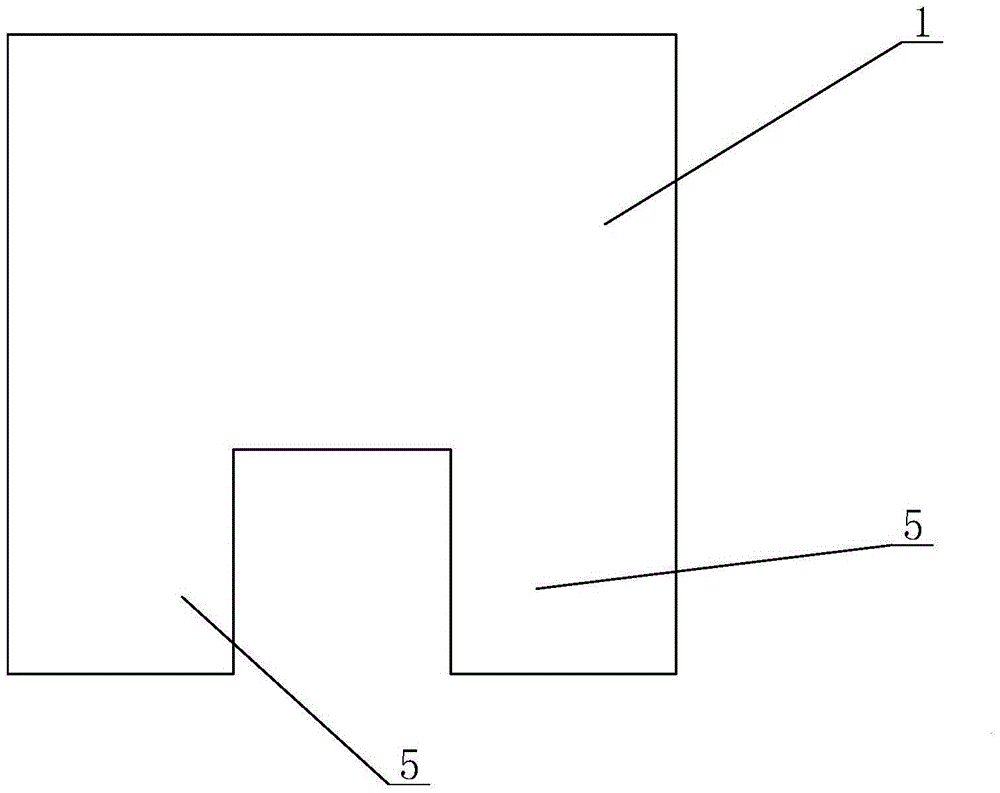

[0026] The cutter head 2 is composed of at least two scraper blades 5 arranged at intervals, and the distance betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com