Automatic detecting and correcting device for light intensity of optical projector

An automatic detection, light-mechanical technology, applied in the field of 3D printing, can solve the problems of affecting the work effect, inconvenient operation, printing failure, etc., and achieve the effect of improving the printing success rate, prolonging the service life and reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

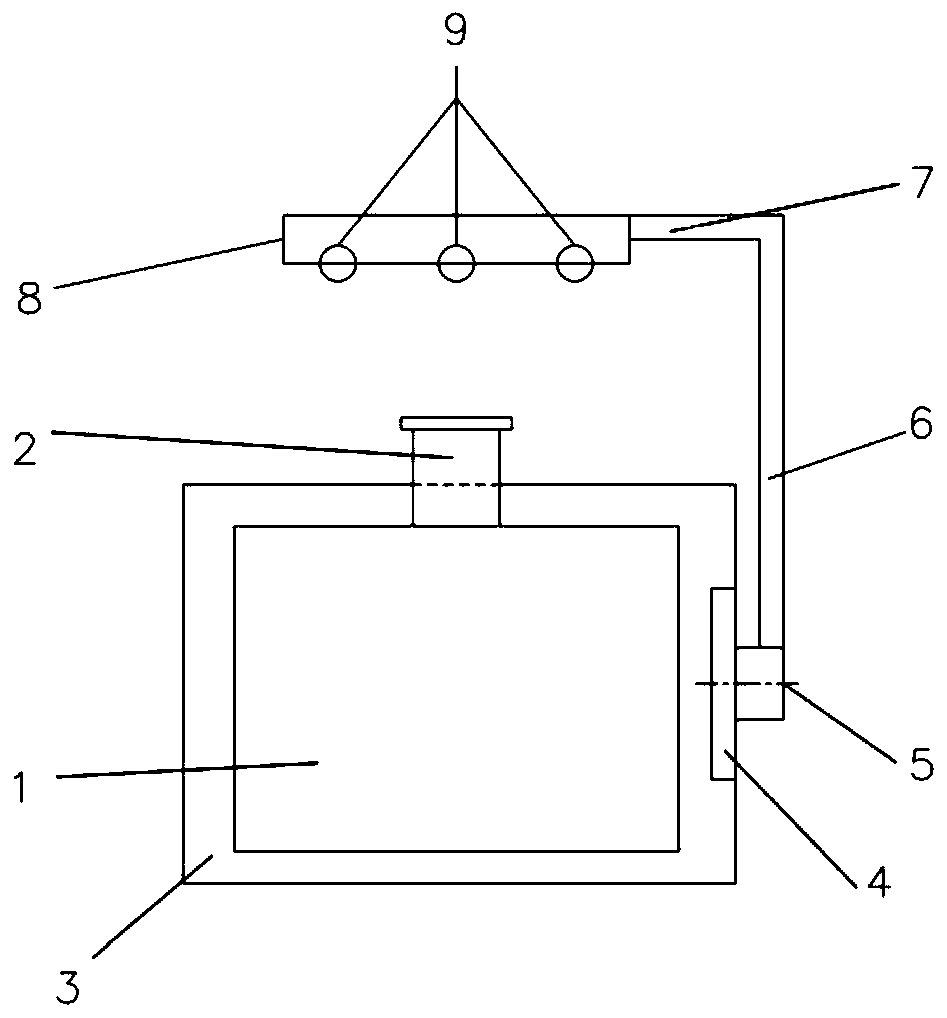

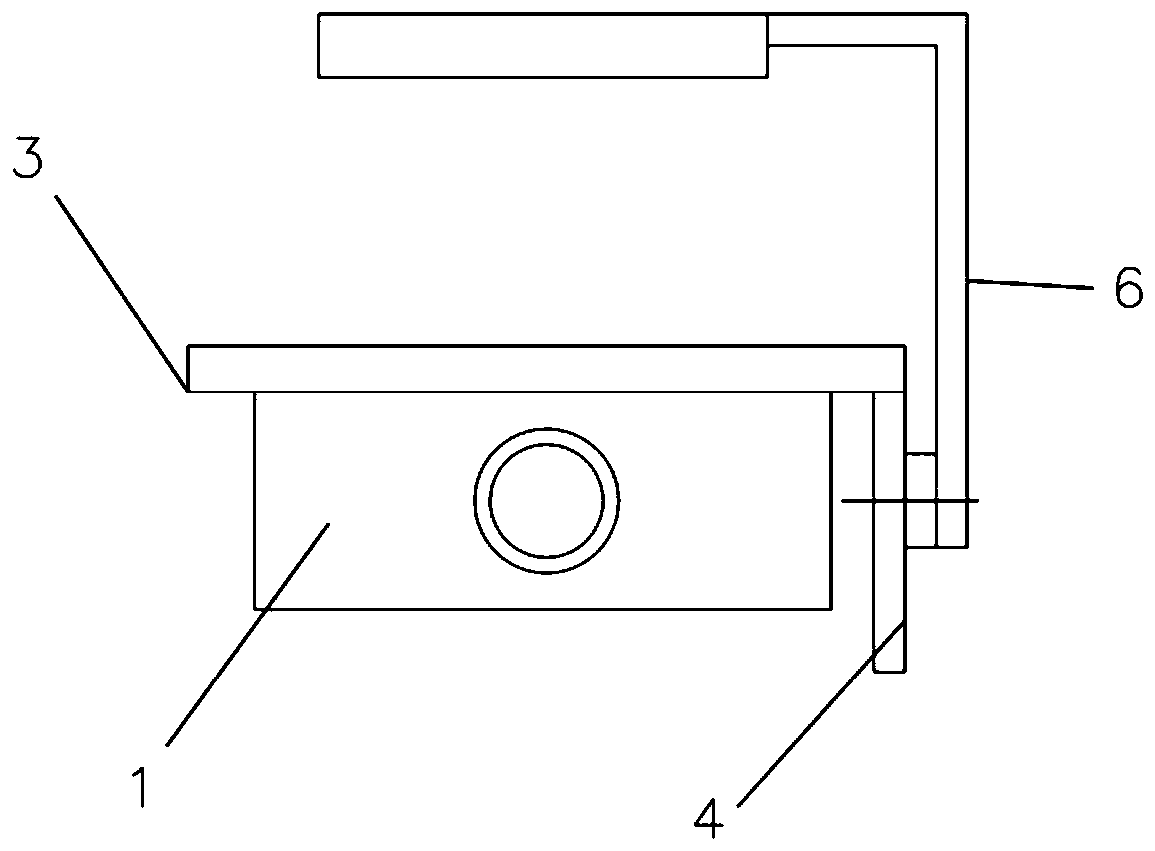

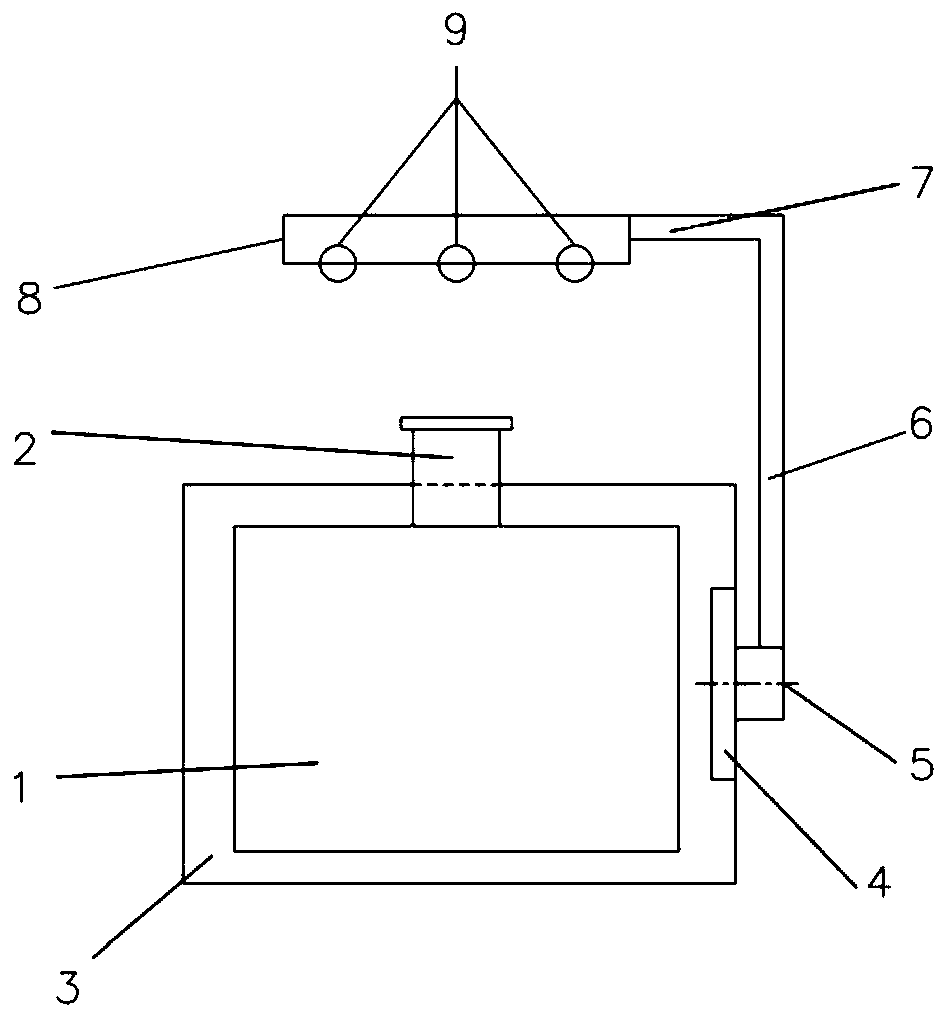

[0020] like figure 1 , figure 2 As shown, it includes an optical machine 1, and the top of the optical machine 1 is provided with a light outlet 2; the optical machine rear cover 3 of the optical machine 1 extends the optical machine mechanism fixing plate 4 to the side of the optical machine 1, and is characterized in that: The fixed plate 4 of the optical mechanical mechanism is provided with a rotating shaft 5; the rotating shaft 5 is fixedly connected with a measuring mechanism 6, and the other end of the measuring mechanism 6 is connected with a working panel 8 through a rotating connecting rod 7; the working When the panel 8 is working, it is rotated by the rotating shaft 5 to the illuminated area above the light outlet 2, and when it is not in the working state, it is rotated by the rotating shaft 5 to the non-illuminated area; there are several sensing devices 9 dotted on the lower surface of the working panel 8; The rotating shaft 5 is connected with the motor, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com