Photosensitive resin printing method without solid supporting

A photosensitive resin, solid technology, applied in the field of 3D printing, can solve the problems of high cost and maintenance cost of high-power laser equipment, long preheating, cooling time, restricting molding accuracy, etc., to reduce the cost of production raw materials, high molding quality, The effect of convenient surface treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

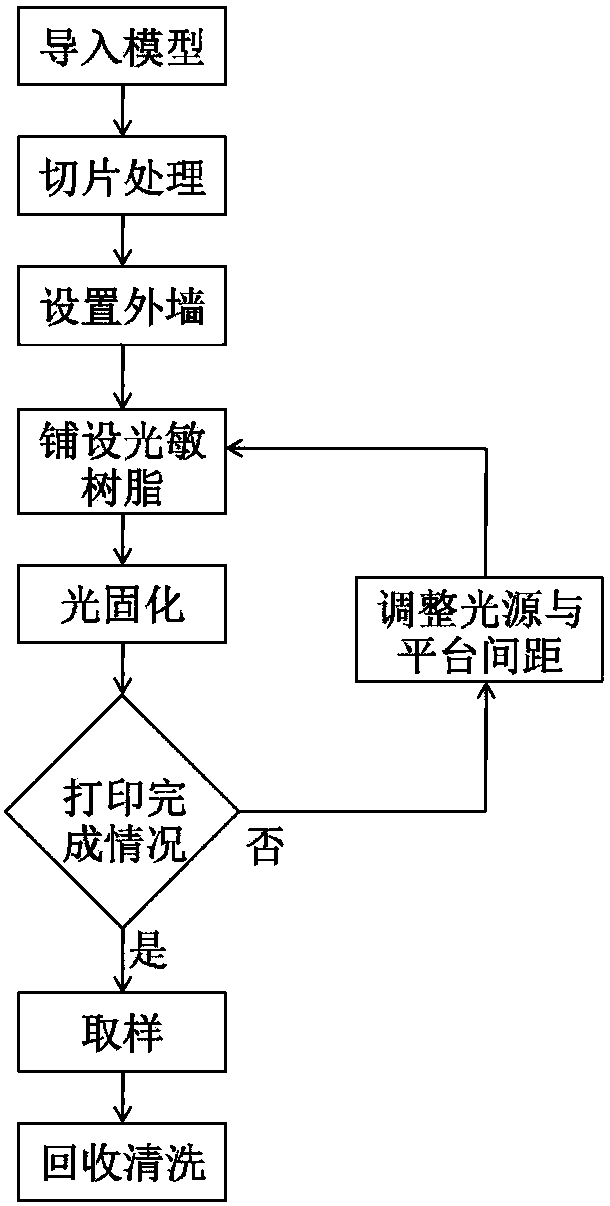

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

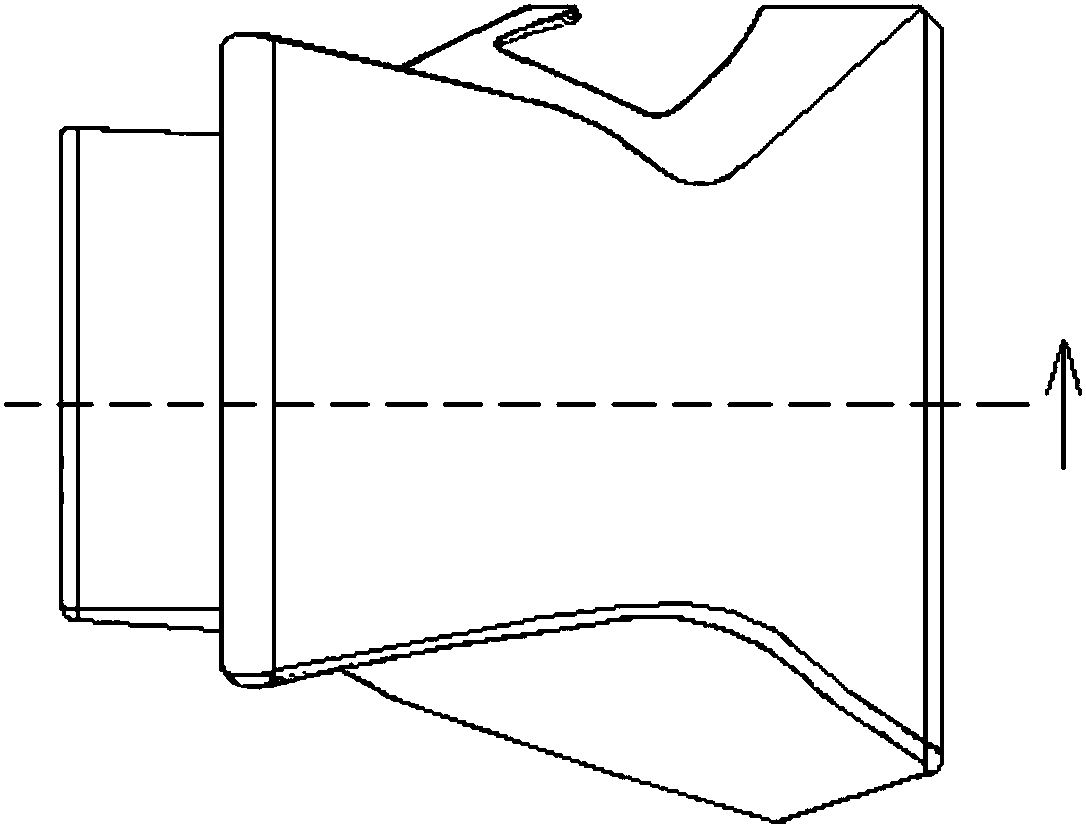

[0020] A photosensitive resin printing method without solid support, which uses layer-by-layer photocuring to process the superimposed photosensitive resin layer in the height direction. The uncured liquid photosensitive resin wraps and fixes the cured workpiece.

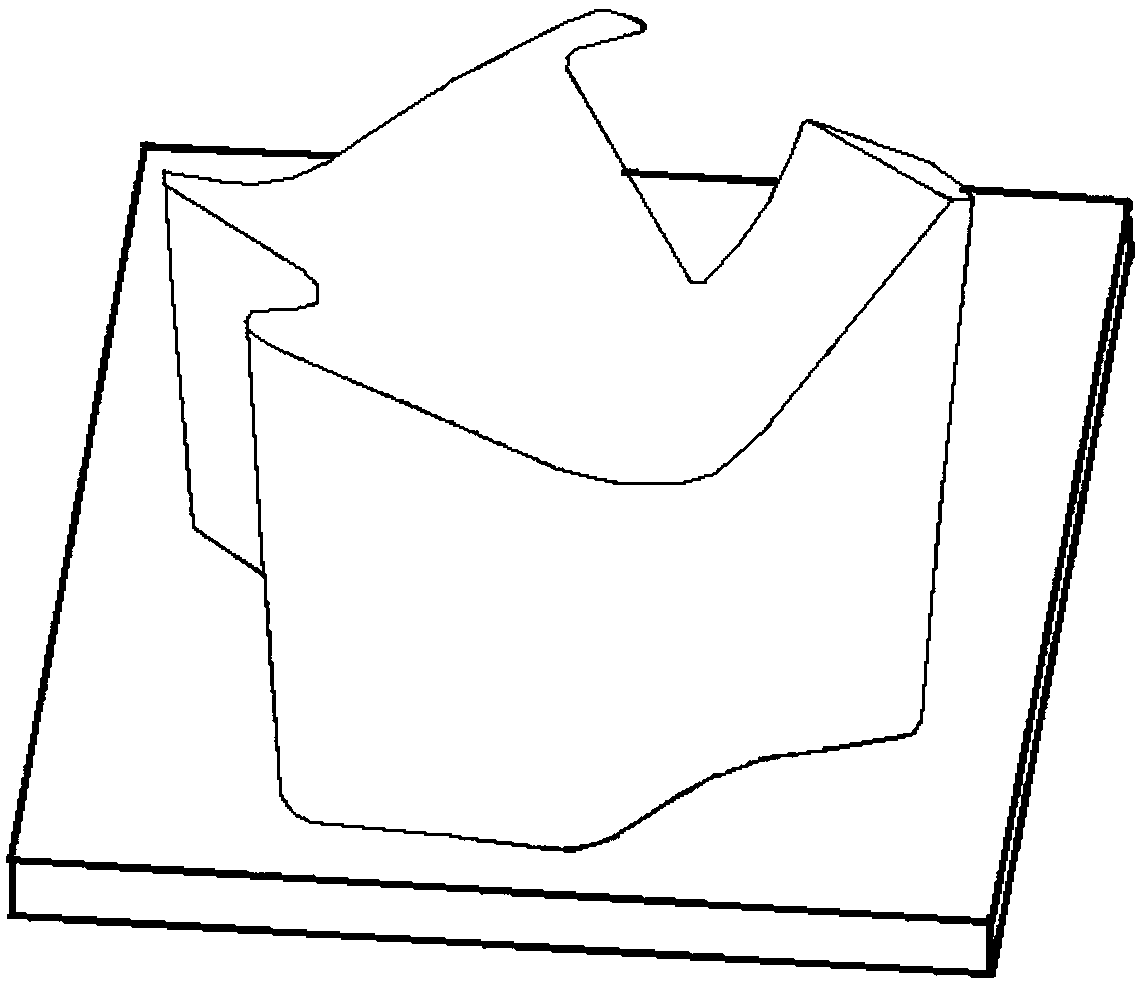

[0021] Before the 3D printing operation, determine the orientation of the workpiece relative to the printing platform; divide the model into several slices layer by layer along the height direction of the printing platform, and obtain the cross-sectional graphics of each slice.

[0022] A closed frame is solidified on the periphery of the cross-sectional figure of each layer of slices; the frames in the slices of several layers are connected to each other to form a closed outer wall.

[0023] During 3D printing, the photosensitive resin layer is laid on the printing platform; the thickness of each photosens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com