Electro hydrodynamic preparation device and method for batch micro-droplets and micro-structures

A preparation device and micro-droplet technology, which is applied in printing and other directions, can solve the problems that liquids with low conductivity are not suitable, increase the difficulty and cost of needle technology, and it is difficult to meet batch preparation, so as to achieve rich templates and printing effects. Overcoming the effect of insensitivity to electric field response and easy repeatability of operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

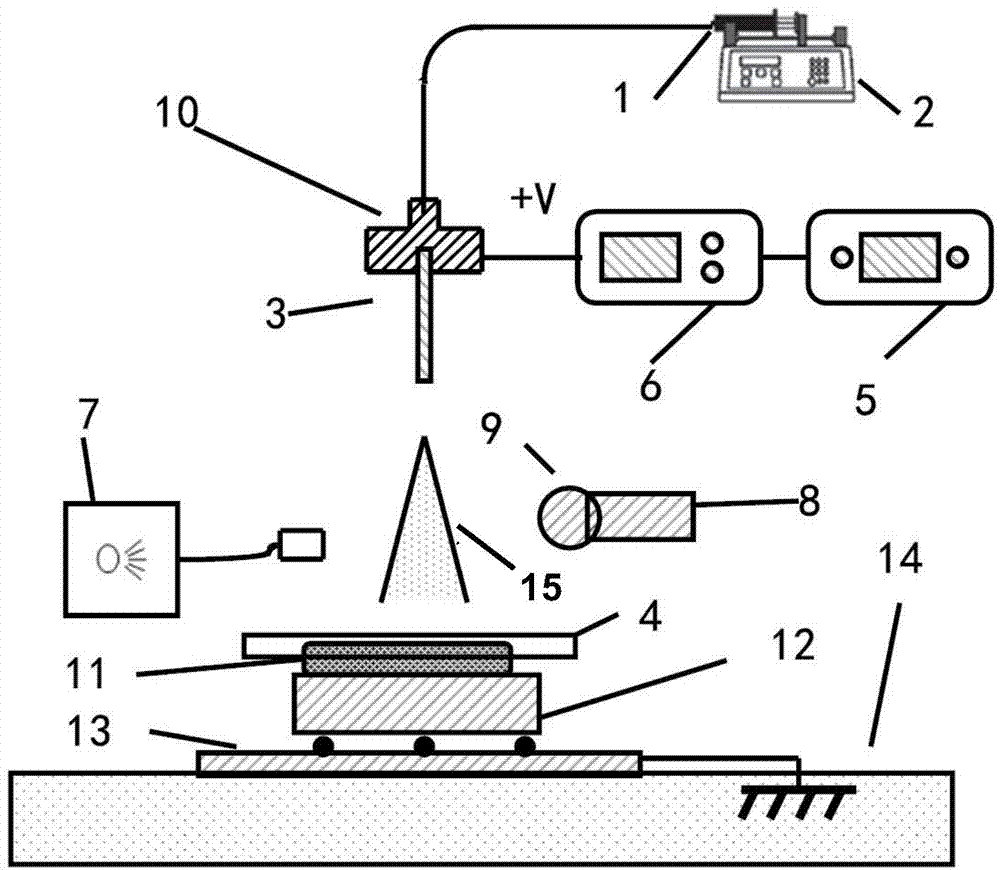

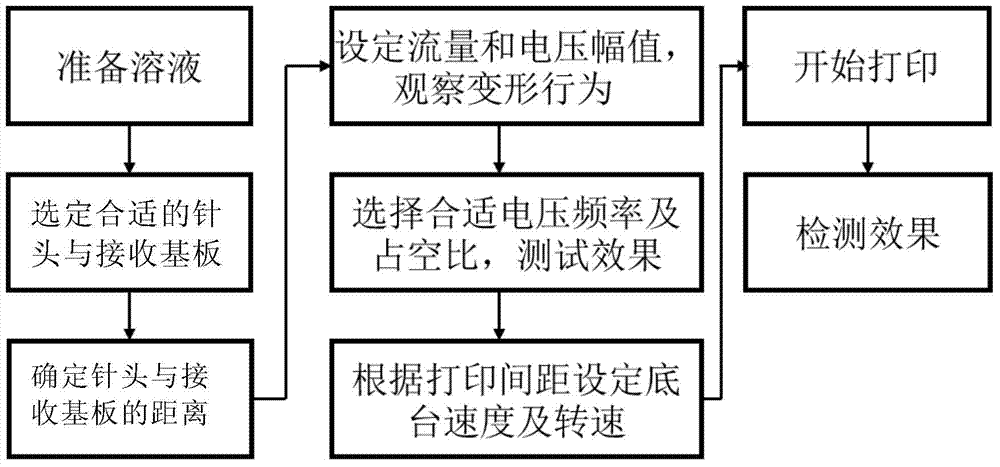

[0063] The present invention also provides a preparation method for electrohydrodynamic preparation of batches of micro-droplets and microstructures, comprising the following steps, such as figure 1 Shown:

[0064] 1) Select or prepare a solution, put it into the syringe 1 and fix it on the micro-injection pump 2;

[0065] 2) According to the selected solution and printing requirements, select the needle head 3 and the receiving substrate 4, and determine the distance between the needle head 3 and the receiving substrate 4;

[0066] 3) Connect the high-speed camera 8 and the high-magnification microscope lens 9, set the frame rate and resolution of the high-speed camera 8, set the voltage amplitude and the flow rate of the needle, test the printing effect, and observe the accumulation and injection of the liquid at the needle 3 in real time According to the observation results, adjust the set parameters to obtain a stable printing process;

[0067] 4) According to the print...

Embodiment

[0078] Step 1. Select pure ethylene glycol solution, draw 1ml into a syringe 1 with a capacity of 1ml, and install it on a micro-injection pump, and push the liquid to the tip of the needle 3 through a hose as a delivery pipe or directly to ensure that the liquid Extrude from the inner diameter of the needle and will not adhere to the outer wall of the needle;

[0079] Step 2. Use a stainless steel needle 3 with an inner diameter of 160 μm and an outer diameter of 310 μm. The receiving substrate is a mirror-finished stainless steel disc 4 with a diameter of 10 mm. The receiving substrate and the z-axis rotating platform 12 are adsorbed and fixed by the vacuum motor 11, the z-axis rotating platform is connected to the x-y motion platform 13, and the distance between the tip of the needle and the receiving substrate is set to 1.5mm;

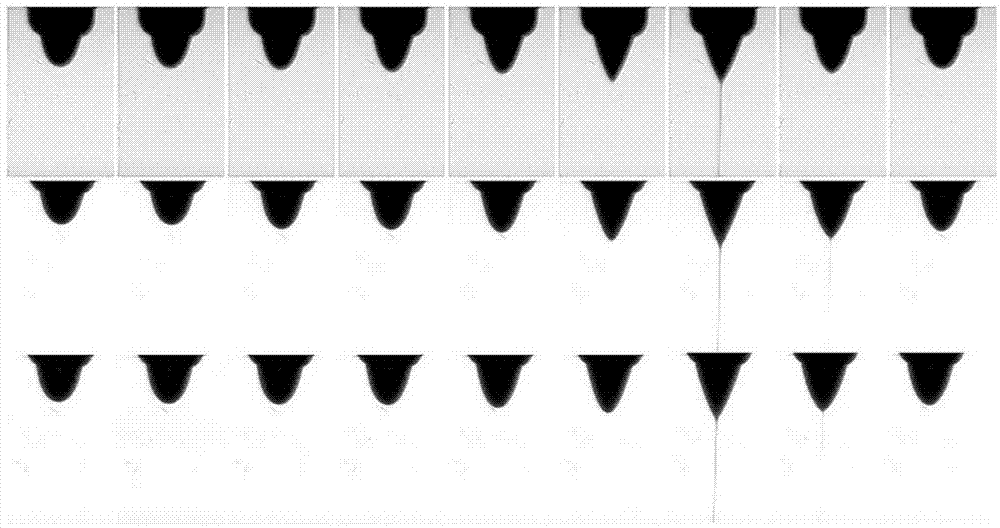

[0080] Step 3. The frame rate of the high-speed camera 8 is set to 10000 frames, the resolution is 372x768, and the magnification of the microlen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com