Synchronous double-side digital printer

A printing machine and digital technology, which is applied in the field of personalized synchronous double-sided digital inkjet printing machine, can solve the problems of different serial numbers, and achieve the effects of straight printing lines, reduced friction, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

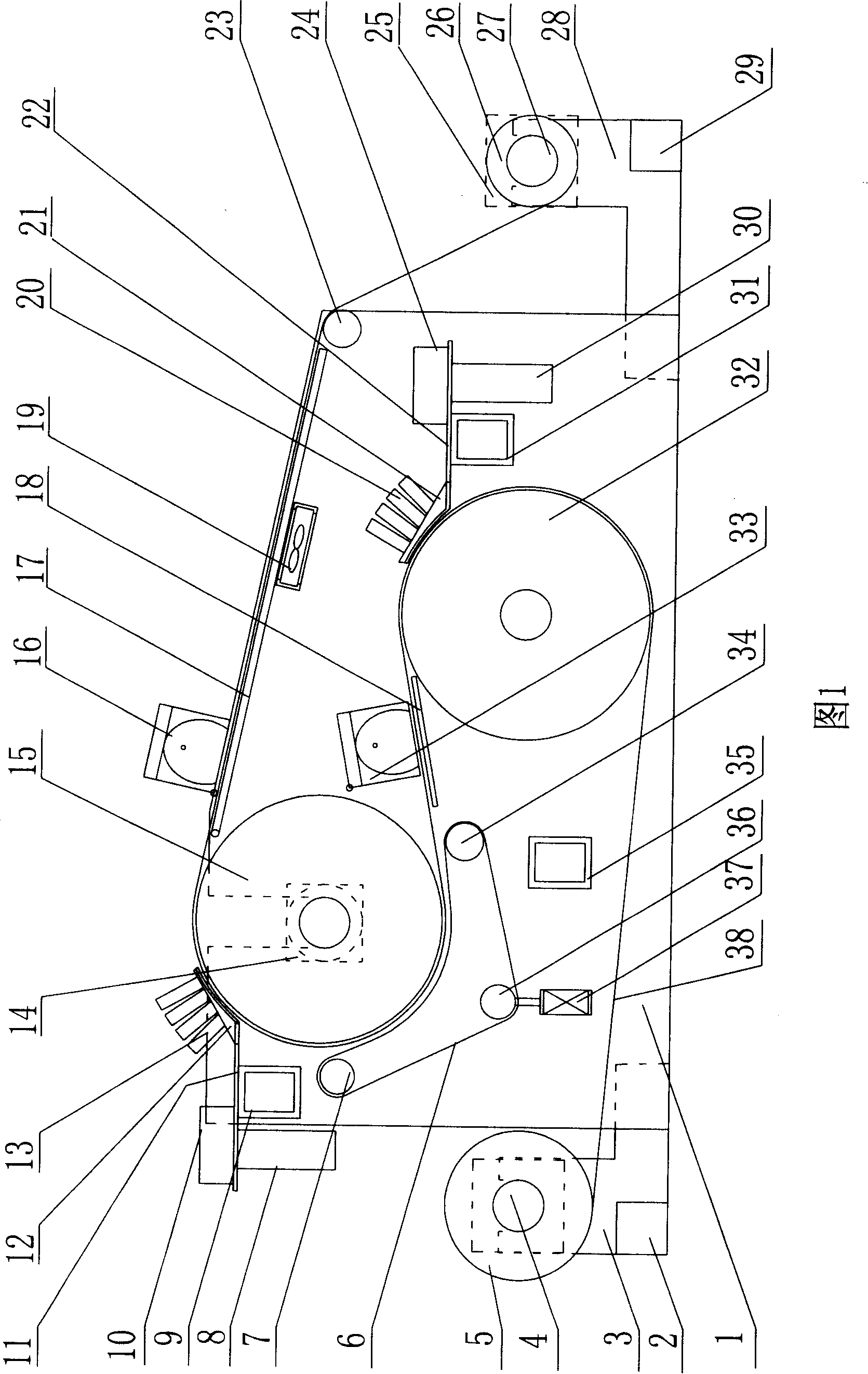

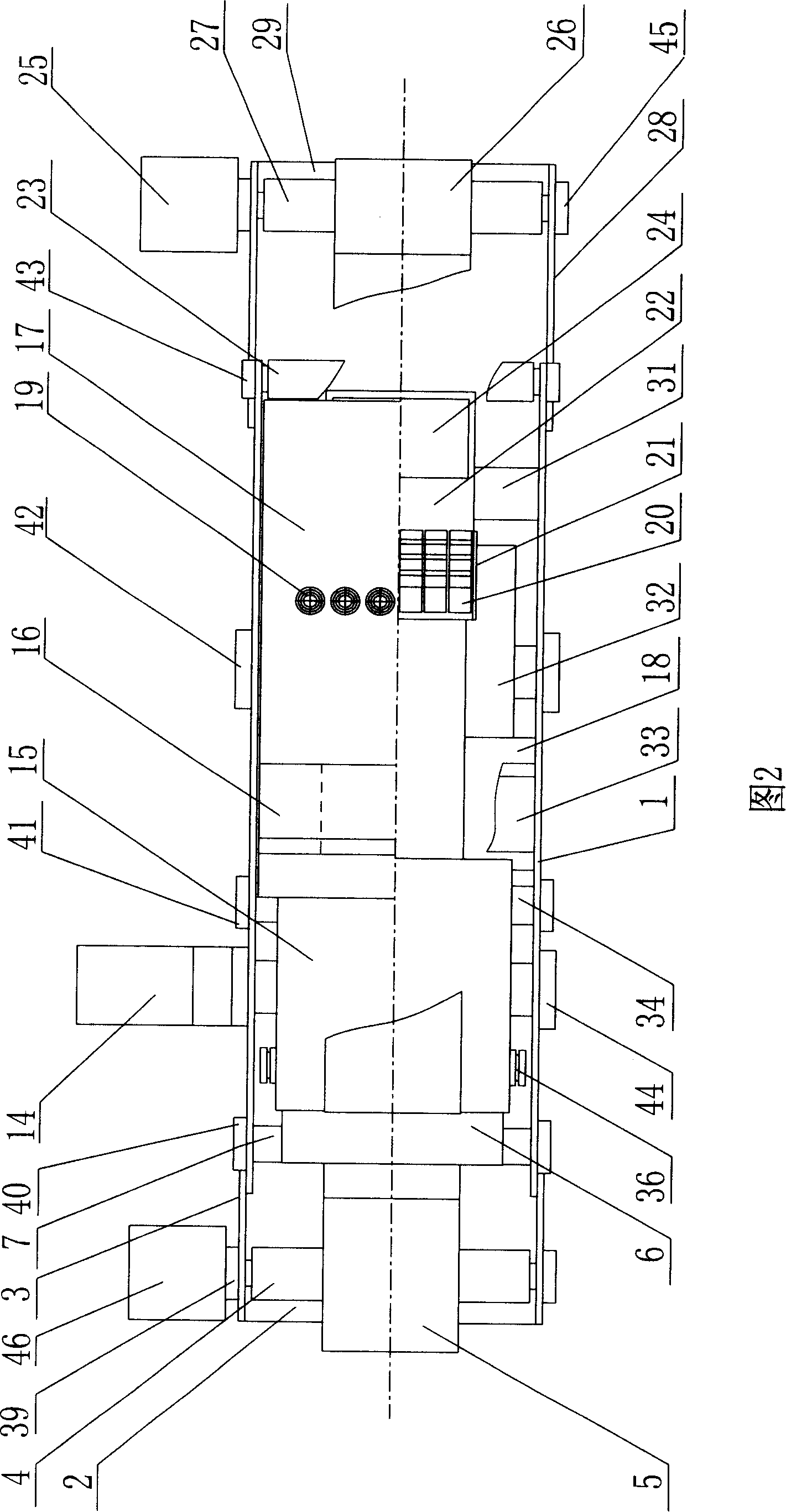

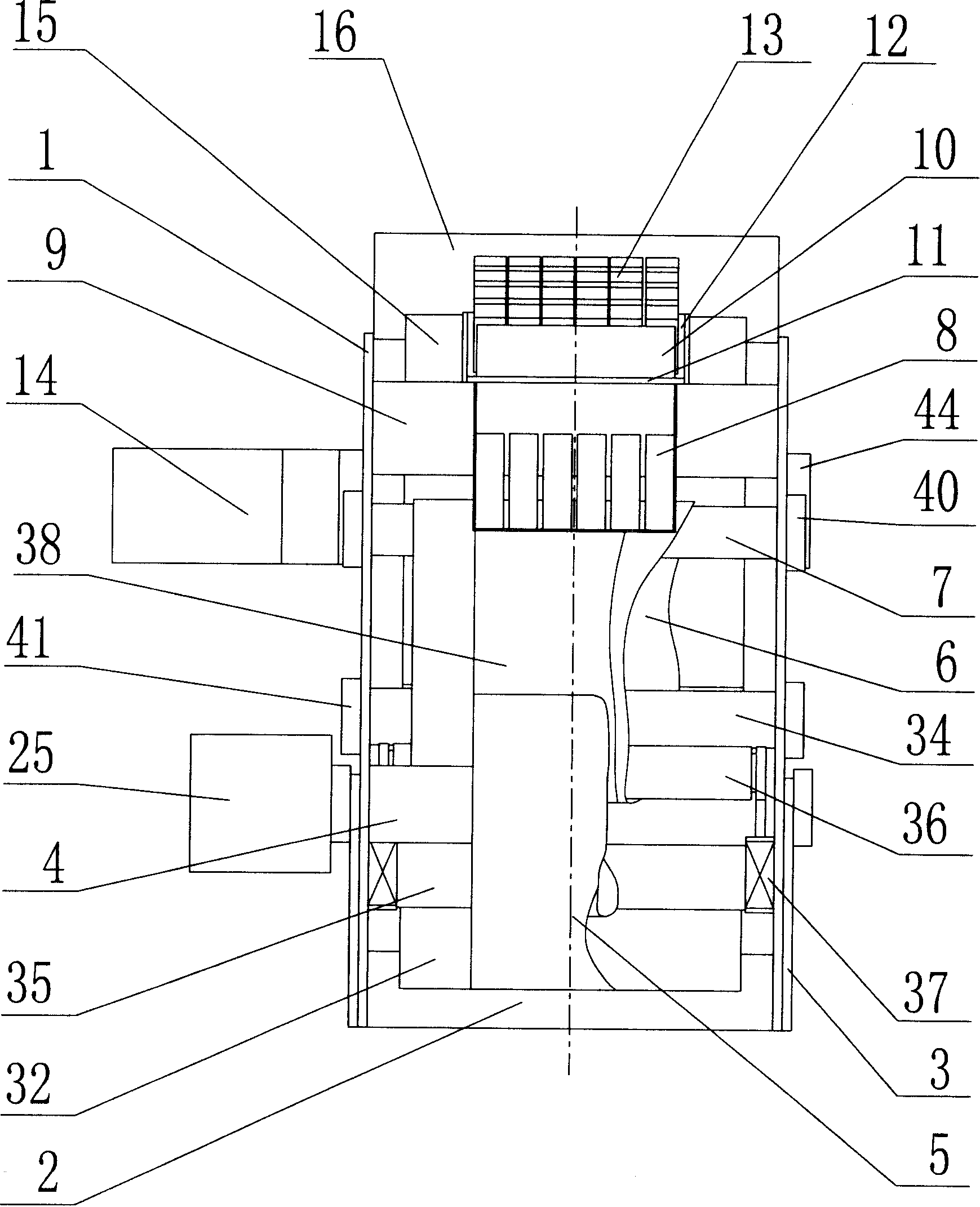

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] As shown in Figures 1 to 5, the present invention includes a wallboard and a feeding device, a receiving device and a guiding device installed thereon. The supporting beams 35 are connected to form the main frame. A positive printing cylinder 15 and a back printing cylinder 32 are arranged between the wallboards 1, both of which have the same diameter. The front printing cylinder 15 is located on the upper left of the back printing cylinder 32, the back printing cylinder 32 is installed on the wall 1 through the back printing cylinder bearing 42, the front printing cylinder 15 is installed on the wallboard 1 through the front printing cylinder bearing 44, and the front printing cylinder motor speed reducer unit 14 Connected to one end of positive printing cylinder 15. The printing material 38 on the feeding device is wound on the back printing cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com