3D printing system based on multi-axis linkage control and machine vision measurement

A machine vision measurement and 3D printing technology, applied in the field of 3D printing, can solve the problems of difficult control of printing accuracy, complex nozzle structure and nozzle driving mechanism, and large space occupied by nozzles, and achieve the effect of simple structure and improved printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to further explain the technical solution of the present invention, it will be described in detail below with reference to the accompanying drawings.

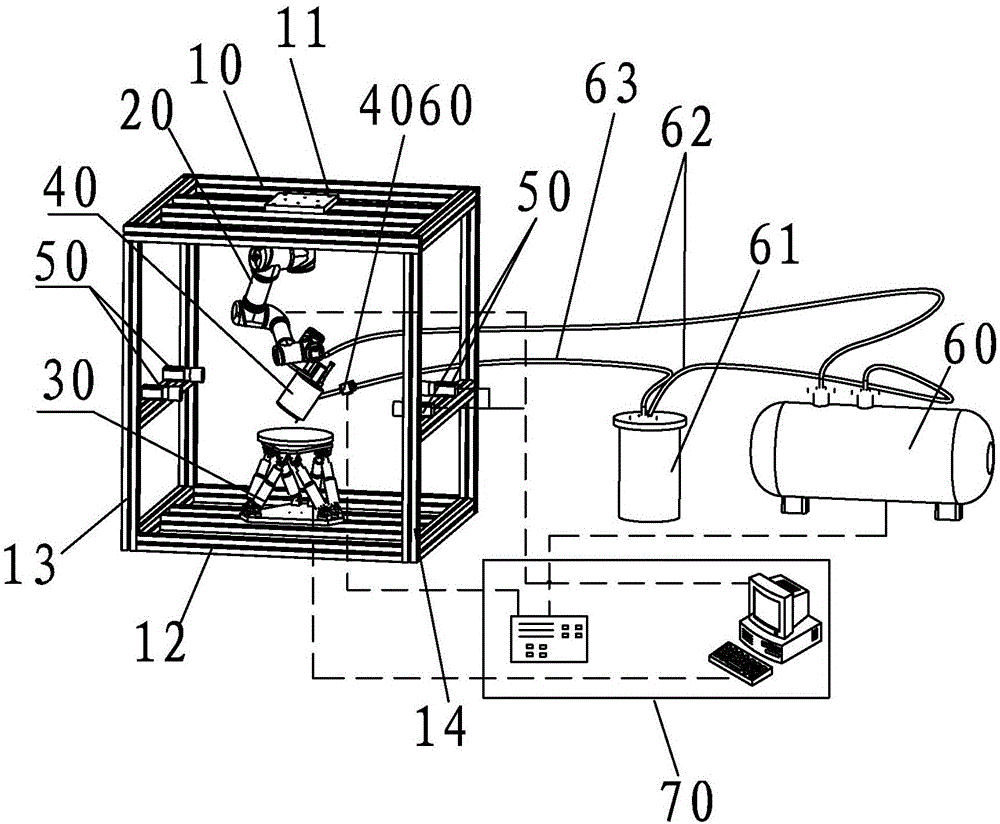

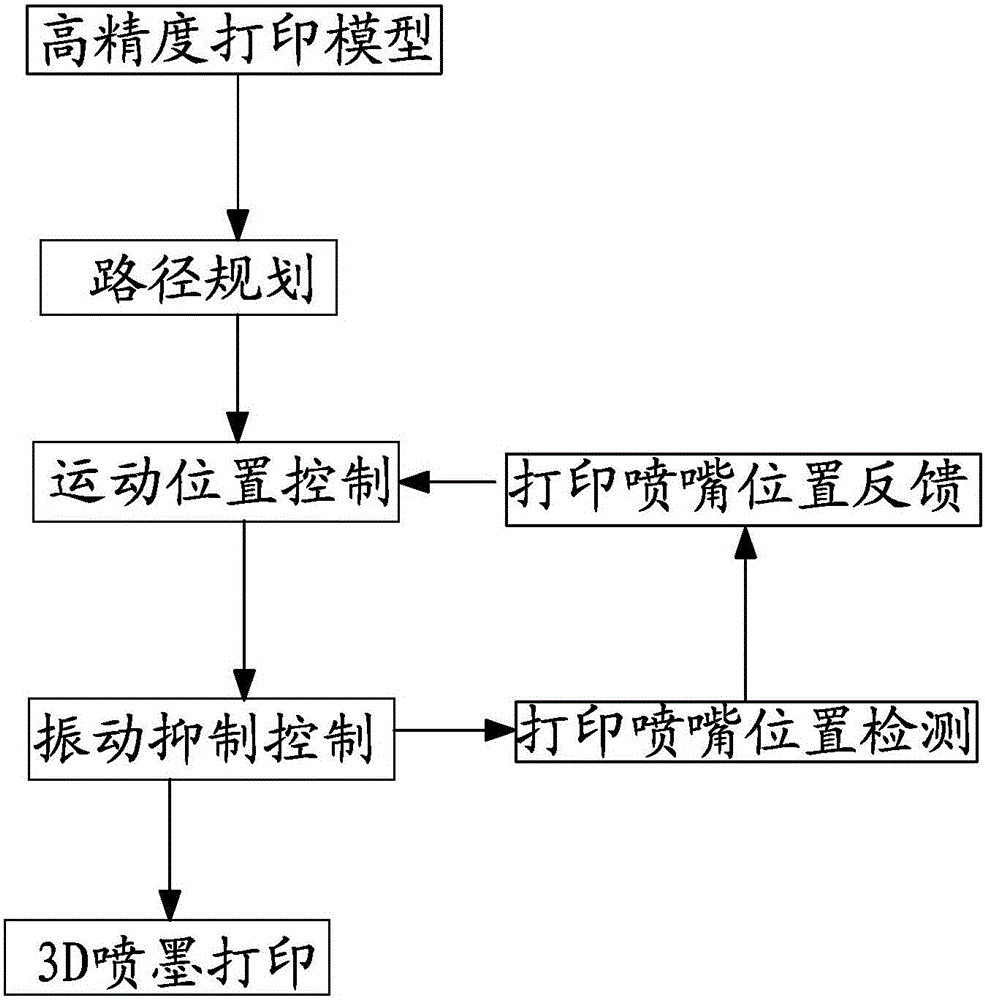

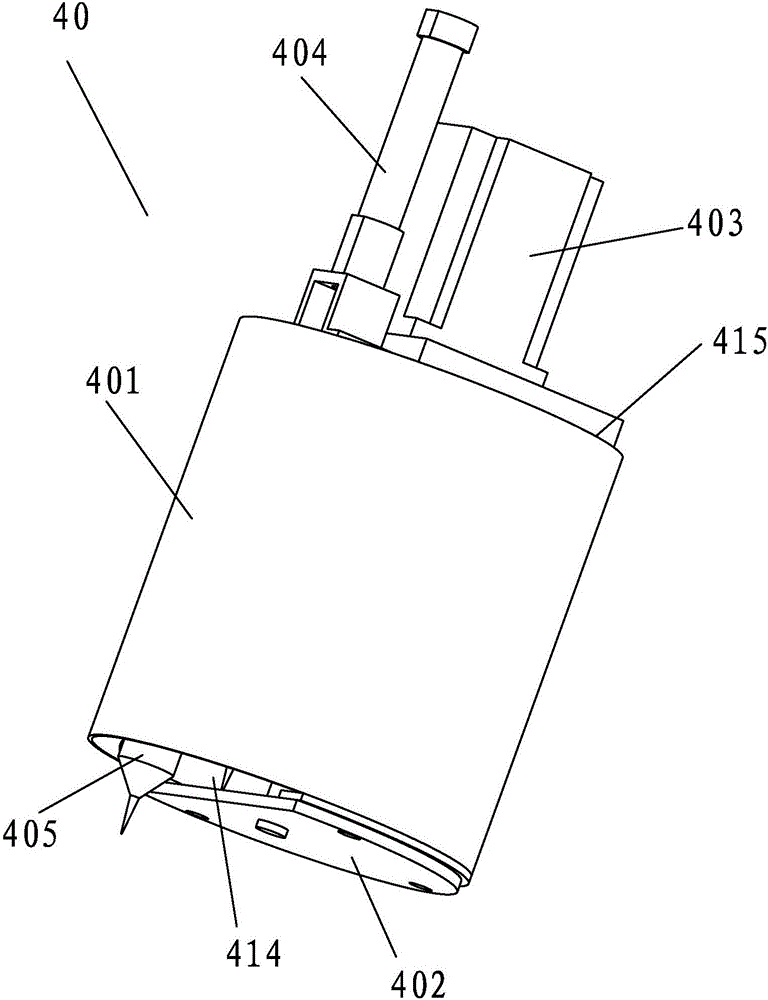

[0048] Reference Figure 1 to Figure 6 , A 3D printing system based on multi-axis linkage control and machine vision measurement, including a frame 10, a worktable for placing artificial bone scaffolds, a printing device 40 arranged above the worktable, and a material conveying system for conveying printing materials The device, the image capture camera 50, the drive mechanism for adjusting the orientation of the printing device 40 and the control system 70, the printing device 40, the material conveying device, the image capture device 50, and the drive mechanism are all connected to the control system 70, and the control system 70 controls each The device works in coordination. The workbench is a six-degree-of-freedom parallel platform 30 connected to the frame 10, the driving mechanism is a six-axis robotic arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com