System and method for multifunctional electric fluid ink-jet printing

一种喷墨打印、电流体的技术,应用在印刷、电路、打字机等方向,能够解决喷嘴易堵塞、不适应高粘度聚合物溶液、液滴尺寸受限喷嘴直径等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

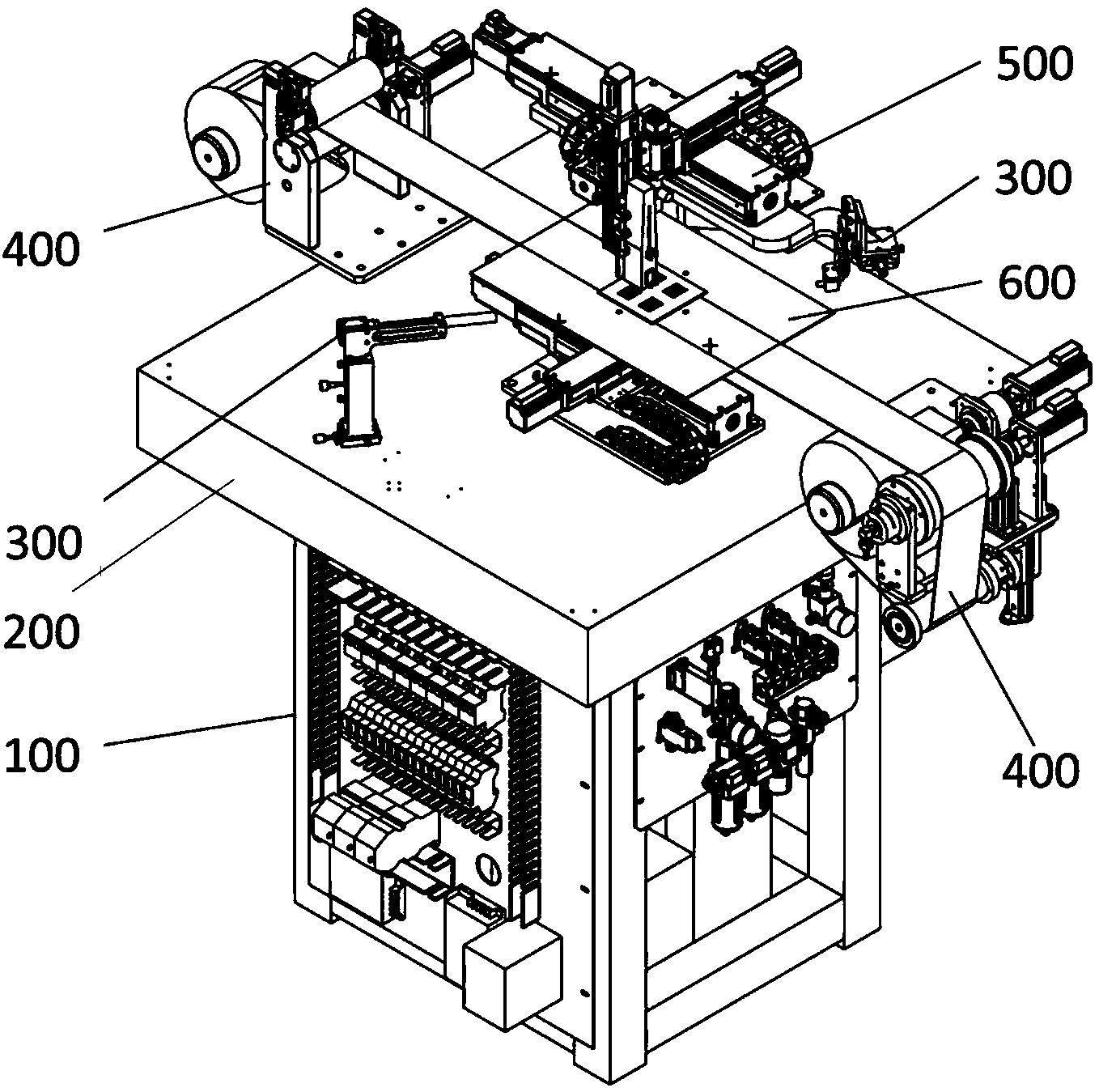

[0091] The printing module 500 and the hard substrate carrying movement module 600 move in cooperation to print patterns on the hard substrate. By adjusting the movement module 600 to initialize it, and the X-axis movement module 602 and the Y-axis movement module 604, the slider moves to the center of its movement stroke. Place hard substrates such as silicon wafers in the center of the adsorption platform, turn on the vacuum pump through the control module, and form negative pressure on the surface of the vacuum platform, the substrate is firmly adsorbed on the adsorption platform, and then adjust the movement of the three movement modules of the printing module 500 , so that the nozzle is facing the edge of the substrate, that is, relative to the zero point of the system. The height of the nozzle from the substrate determines the printing mode, which can be selected according to the needs after being calibrated through experiments. After the specific position is reached, t...

example 2

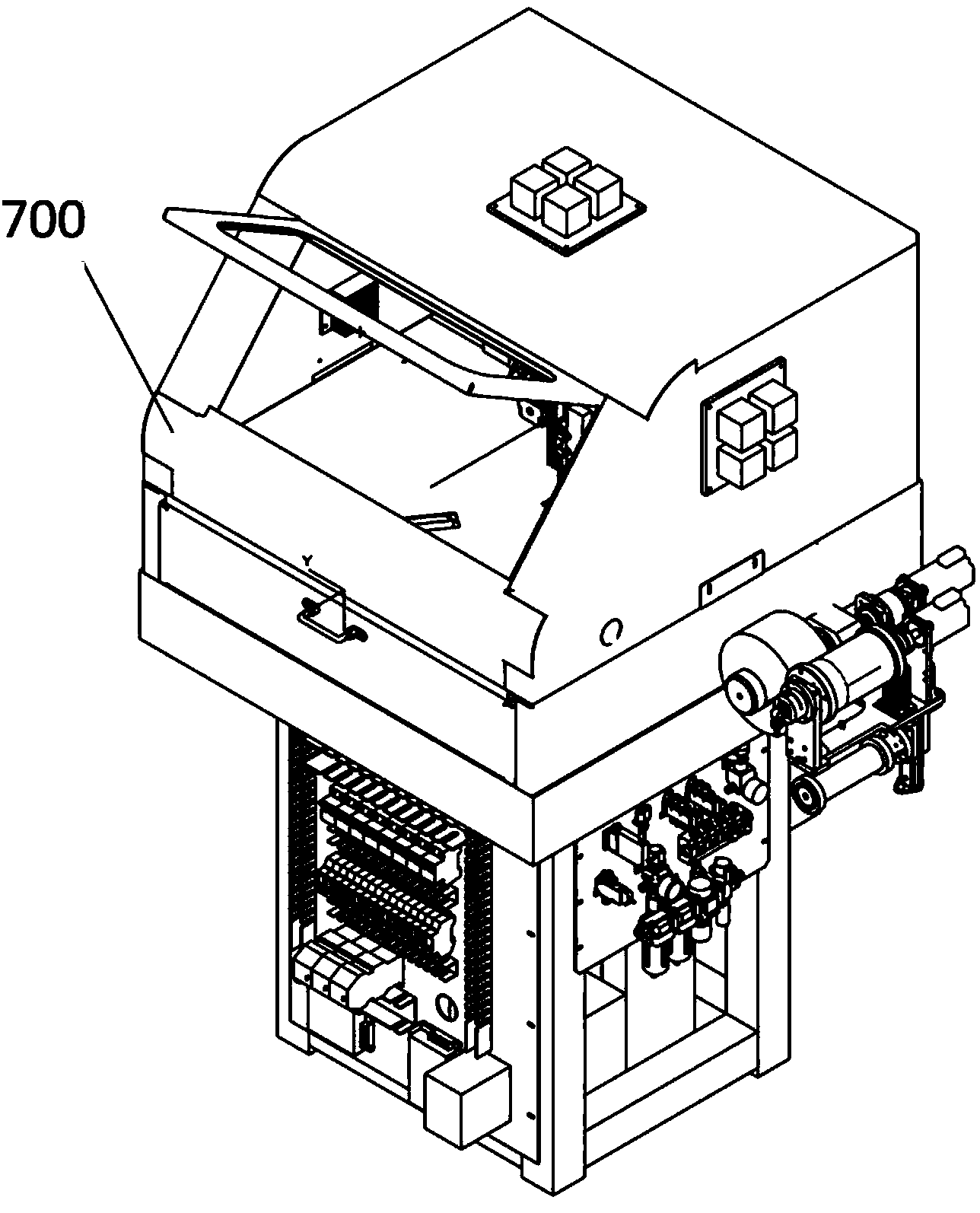

[0093] The roll-to-roll film substrate conveying module 400 cooperates with the jet printing module 500 to print patterns on the flexible substrate. In this working mode, the roll-to-roll film substrate conveying module 400 is responsible for conveying the substrate in a single direction, and the specific printing pattern movement is realized by the jet printing module 500 . Firstly, the material roll is installed on the discharge roller 420 of the front-end discharge part of the roll-to-roll film substrate conveying module 400, passes through the direct gap between the upper and lower rollers of the counter-roller 430, is placed on the adsorption platform, and finally wound on the rear-end receiving part On the rewinding roller, its specific mode and motion state such as Figure 19 shown. Before printing, the hard substrate module returns to the initial position, at this time the thin film substrate is just above the adsorption platform, and then remains in a static state. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com