Small diameter metal pipe long-range lining glass reinforced plastic hose repairing method

A technology of metal pipes and glass fiber reinforced plastics, applied in the direction of pipes/pipe joints/fittings, pipe components, mechanical equipment, etc., can solve the problems of reducing infusion volume, small channel area, and reducing the area of original pipeline channels, so as to save repair costs, The effect of reducing technical difficulty and simplifying the on-site repair process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

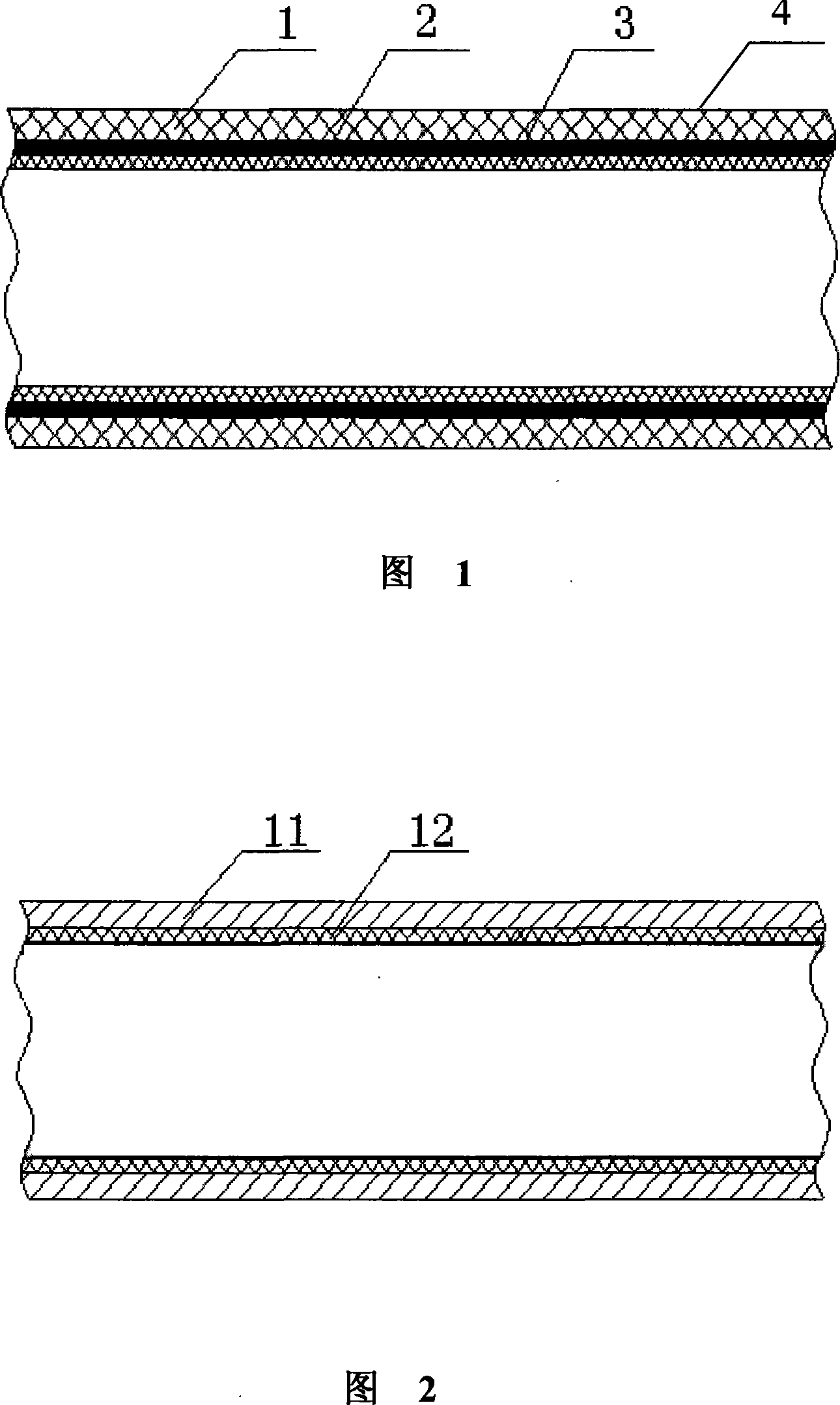

[0022] As shown in Figure 1, the FRP hose 4 is composed of a hose blank 1, an adhesive layer 2, and a soft rubber hose 3, wherein the hose blank 1 is tubular and seamless, and the material is chemical fiber or inorganic fiber, such as polyester fiber, polypropylene fiber, polyester fiber, acrylic fiber, spandex fiber or glass fiber, or a combination of several fibers; of course, it is not limited to the aforementioned fibers, as long as the fiber has a certain strength and is suitable for weaving, It can be resistant to liquid corrosion in pipelines such as crude oil and sewage. Wherein the polyester fiber is preferably a thermoplastic saturated polyester fiber, which can be obtained by injection molding of a thermoplastic saturated polyester resin through a spinneret, because the resin has the characteristics of high mechanical strength, good corrosion resistance to crude ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com