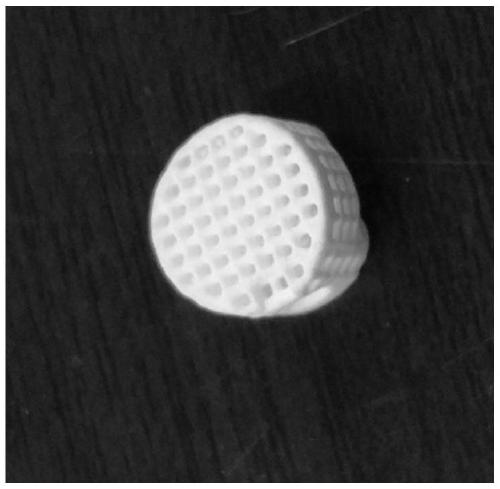

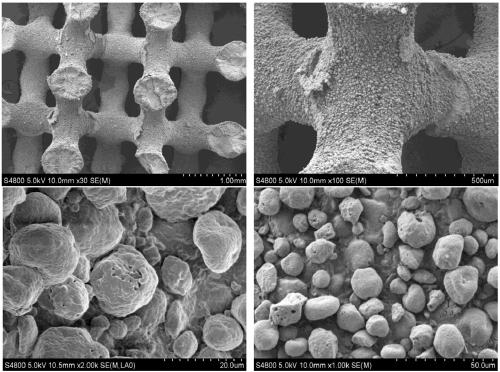

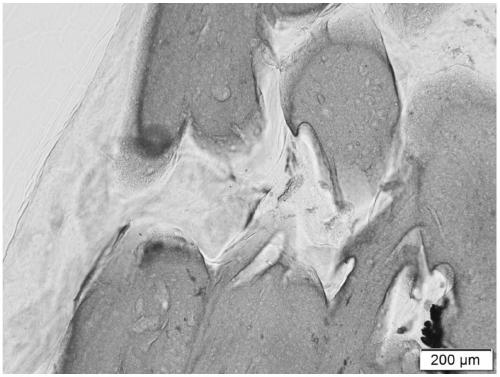

Calcium phosphate bone induction biological ceramic stent based on photocuring 3D printing technology and preparation method thereof

A technology of calcium phosphate ceramics and bioceramics, applied in the field of biomedical materials, can solve the problems of difficult to repair stents, difficult to accurately control the size and porosity of the pore structure of the stents, etc., and achieves fast printing speed, good molding effect, and fluidity. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Preparation of photosensitive resin premix: select 50wt% epoxy acrylate as oligomer, 44wt% TMPTA as reactive diluent, 5wt% 819 as photoinitiator, 1wt% EDB as sensitizer, Mix well with a magnetic stirrer for 20 min.

[0041] (2) Use hydroxyapatite with a purity of 99.9% (60% by mass), the prepared photosensitive resin premix (37% by mass), and KH-570 silane coupling agent as a dispersant (60% by mass) 3%) was placed in a ball mill at a speed of 150r / min, and ball milled for 10 hours to obtain a ceramic-resin slurry.

[0042] (3) Put the ceramic-resin slurry under the DLP light curing machine for printing, the wavelength is 405nm, the printing layer thickness is 50μm, the light time is 5s / layer, and the layers are stacked and accumulated to form a ceramic green body.

[0043] (4) After removing the support from the printed ceramic green body, place it in a muffle furnace for sintering and degreasing. Raise the temperature at a rate of 5°C / min, raise the temperature ...

Embodiment 2

[0046] (1) Preparation of photosensitive resin premix: select 59wt% epoxy acrylate as oligomer, 35wt% TMPTA as reactive diluent, 5wt% 819 as photoinitiator, 1wt% EDB as sensitizer, Mix well with a magnetic stirrer for 20 min.

[0047] (2) Same as step (2) in Example 1.

[0048] (3) Same as step (3) in Example 1.

[0049] (4) After removing the support from the printed ceramic green body, place it in a muffle furnace for sintering and degreasing. Raise the temperature at a rate of 5°C / min, raise the temperature to 800°C and keep it for 3 hours, then raise the temperature at a rate of 5°C / min to 1200°C, keep it for 5 hours, and then cool down with the furnace to obtain a porous calcium phosphate ceramic support with a ceramic porosity of 65. %.

[0050] The content of the reactive diluent in this embodiment selects the lowest value of the optional mass fraction range, and the sample can be successfully printed.

Embodiment 3

[0052] (1) Same as step (1) in Example 1.

[0053] (2) Use hydroxyapatite with a purity of 99.9% (50% by mass), the prepared photosensitive resin premix (47% by mass), and KH-570 silane coupling agent as a dispersant (proportion by mass 3%) was placed in a ball mill at a speed of 150r / min, and ball milled for 10 hours to obtain a ceramic-resin slurry.

[0054] (3) Same as step (3) in Example 1.

[0055] (4) After removing the support from the printed ceramic green body, place it in a muffle furnace for sintering and degreasing. Raise the temperature at a rate of 5°C / min, raise the temperature to 800°C and keep it for 3 hours, then raise the temperature at a rate of 5°C / min to 1200°C, keep it for 5 hours, and then cool down with the furnace to obtain a porous calcium phosphate ceramic support with a ceramic porosity of 73 %.

[0056] In this embodiment, the mass ratio (solid content) of hydroxyapatite is selected from the lowest value in the optional range, and the sample ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com