Processing method of invisible braces

A processing method and a technology of invisible braces, which are applied in dentistry, orthodontics, and dental prosthetics, etc., can solve the problems of excessive printing raw materials, waste of raw materials, and high transportation costs, so as to save transportation costs, reduce production costs, and optimize processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

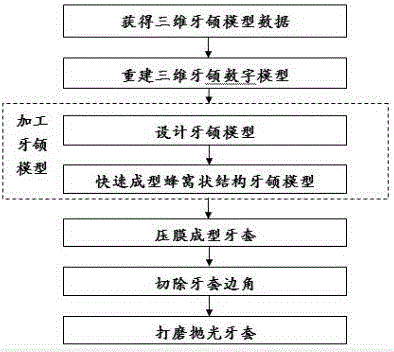

[0022] The processing method of the invisible braces includes a step of processing the dental model, and the processing step of the dental model includes:

[0023] 1) Design the jaw model

[0024] Using three-dimensional graphics processing software to design the target dental model, the interior of the dental model is with an internal support structure;

[0025] 2) Rapid prototyping dental model with internal support structure

[0026] The 3D printing equipment is used to rapidly form the dental model with internal support structure.

[0027] Before the step of processing the dental model, it also includes obtaining the three-dimensional dental model data and rebuilding the three-dimensional digital model of the dental jaw. After the step of processing the dental model, it also sequentially includes molding the dental braces, cutting the corners of the dental braces, and grinding and polishing. braces.

[0028] The interior of the dental model is provided with an internal ...

Embodiment 2

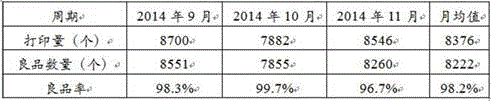

[0052] Embodiment 2: Dental model test test

[0053] In this embodiment, the weight, yield rate and dental model parameters of the finished dental model are tested.

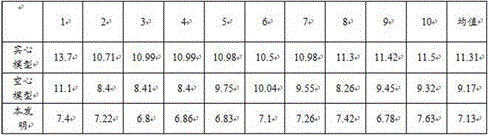

[0054] This test carries out weight test to three different types of jaw models, which are respectively solid model, hollow model and the model with internal support structure of the present invention, each processing 10, and detecting its weight, specifically refer to the following table 1.

[0055] Table 1 Weight comparison of different jaw models (unit: g)

[0056]

[0057] By comparing the weight of the solid model, the hollow model and the model of the present invention, as can be seen from Table 1, the weight of the model made by the present invention is the lightest, which reduces by 22.3% compared with the hollow model, and the weight of the hollow model is relative to the solid model Reduced by 18.9%, and the strength of the model made by the present invention meets the production requirements. This s...

Embodiment 3

[0064] Example 3: Acquisition of dental model with internal support structure

[0065] (1) Following the honeycomb shape of bees, the hexagonal grid structure is used as the reinforcement structure of the prototype of the dental model.

[0066] (2) The data size selected in the internal support structure involved in the present invention refers to the size of the jaw model: in the usual measurement data, in the direction of the horizontal section of the jaw model, the incisor part at the narrowest part of the gum is 7mm As mentioned above, the molar part is generally above 12mm, so the size of the inscribed circle of the hexagonal grid structure is selected to be below 5mm, and a sufficient test has been done on this size. See Table 3 for the test comparison table. On the basis of functional materials, the rules of shelling 1.6mm, mesh opening 5mm, and grid wall thickness 0.6mm are adopted for design and manufacture.

[0067] (3) The specific operation steps are as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com