Powder bed 3D printing equipment size adjustable and controllable platform

A 3D printing, powder bed technology, applied in processing platforms/substrates, manufacturing, solid material additive processing, etc., can solve problems such as poor compatibility, reduce printing costs, improve printing efficiency, and save printing materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

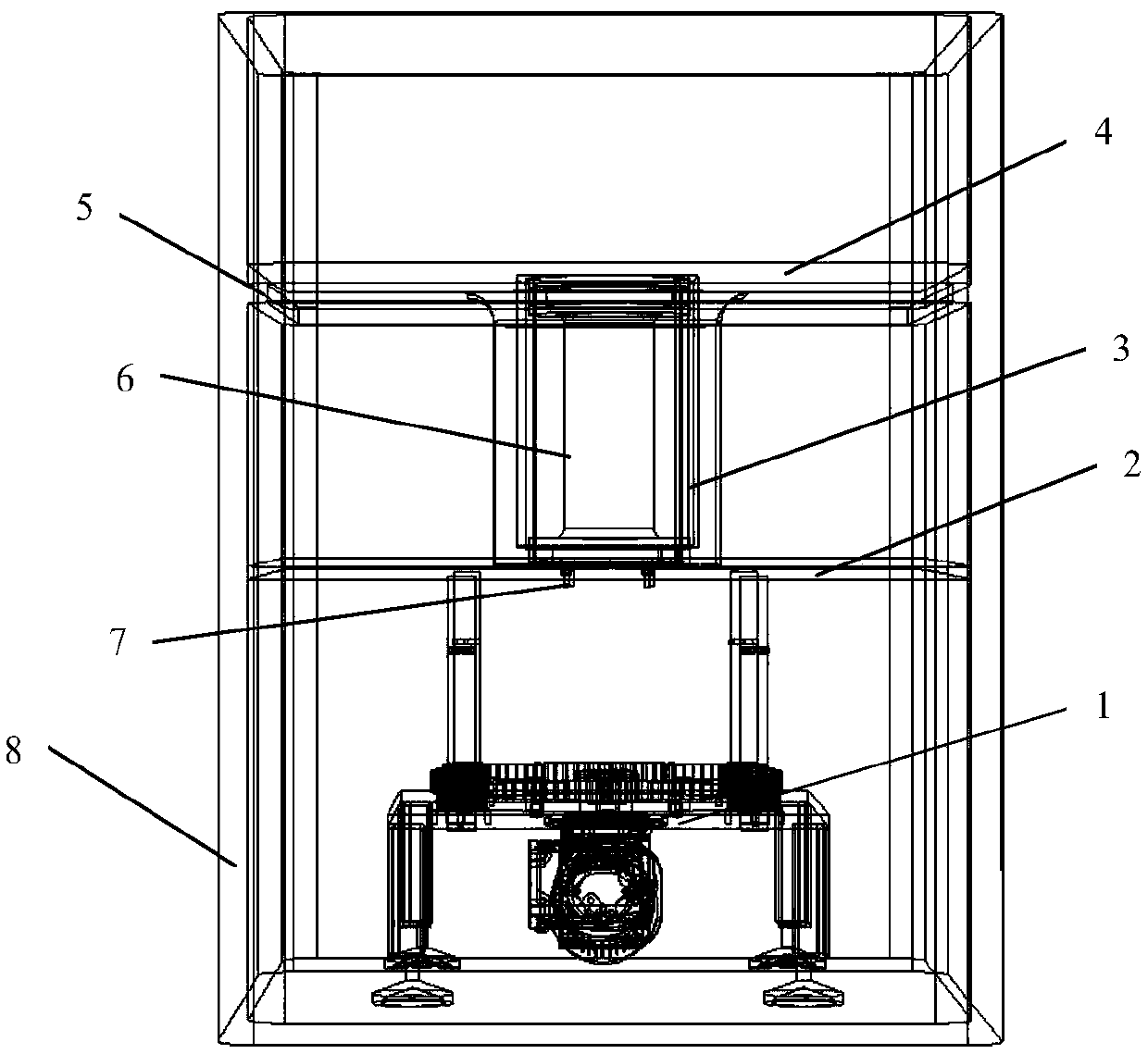

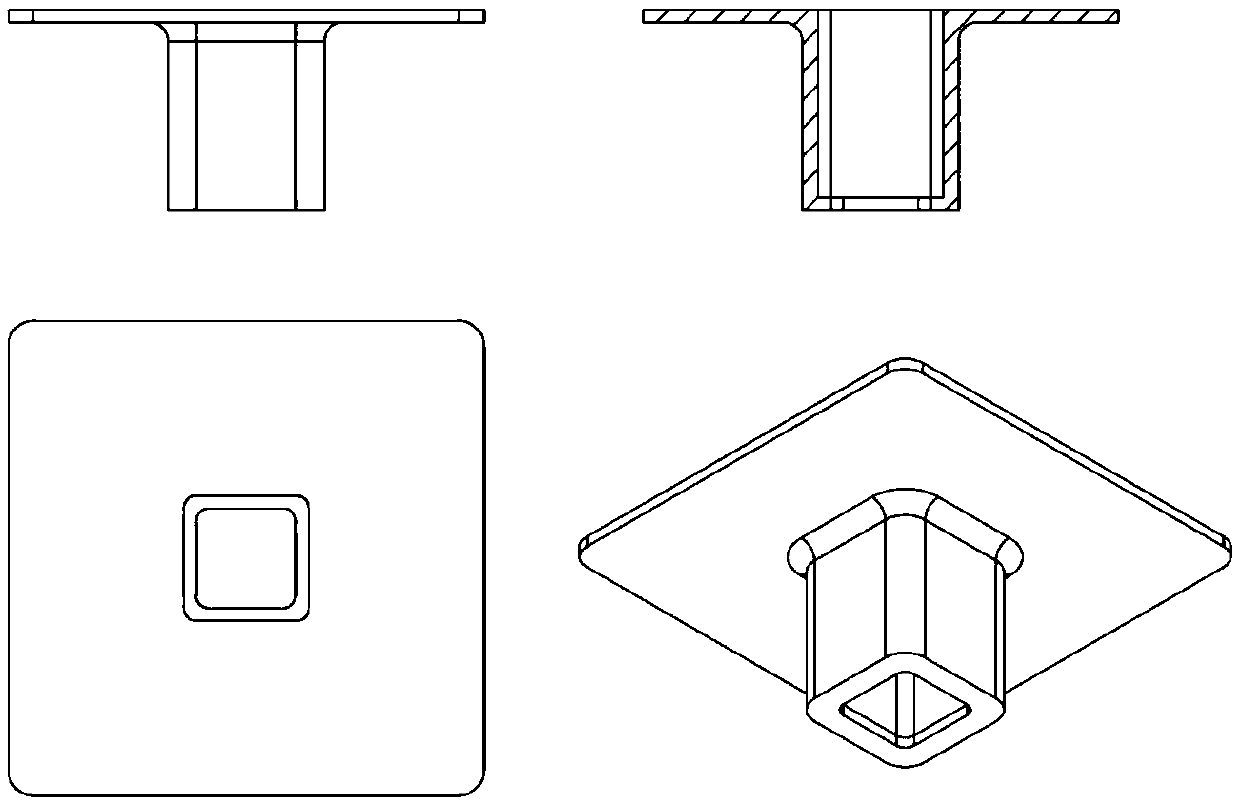

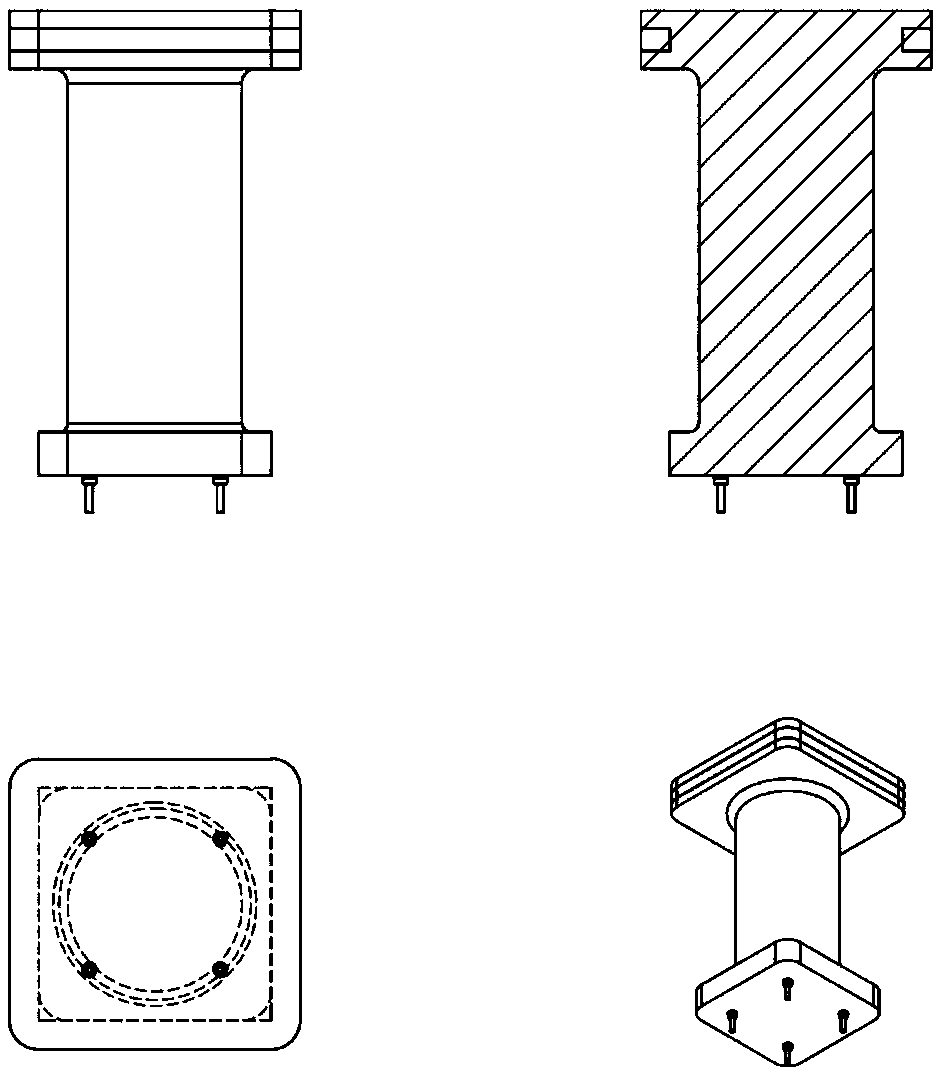

[0017] The following examples refer to Figure 1-7 .

[0018] The size-adjustable platform of the powder bed 3D printing equipment of the present invention includes a power system 1, a printing workbench 2, a circular sleeve or a square sleeve 3, a fixed circular inner cavity workbench or a fixed square inner cavity workbench 4, a convex Table structure 5, movable circular worktable or movable square worktable 6, connecting hole 7 and printing equipment outer cylinder 8.

[0019] A fixed circular inner cavity workbench or a fixed square inner cavity workbench 4 is divided into two parts: a table top and a connecting track. During the working process, the movable circular workbench or the movable square workbench 6 is driven by the power system 1 to move up and down in the connecting track.

[0020] The movable circular workbench or the movable square workbench 6 is mainly composed of three parts, the uppermost part is the working part of the tabletop, the lower part is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com