Shell-shaped component light modeling system for 3D (three-dimensional) printing

A 3D printing and lightweight technology, applied in 3D modeling, image data processing, special data processing applications, etc., can solve the problem of less research on shell models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

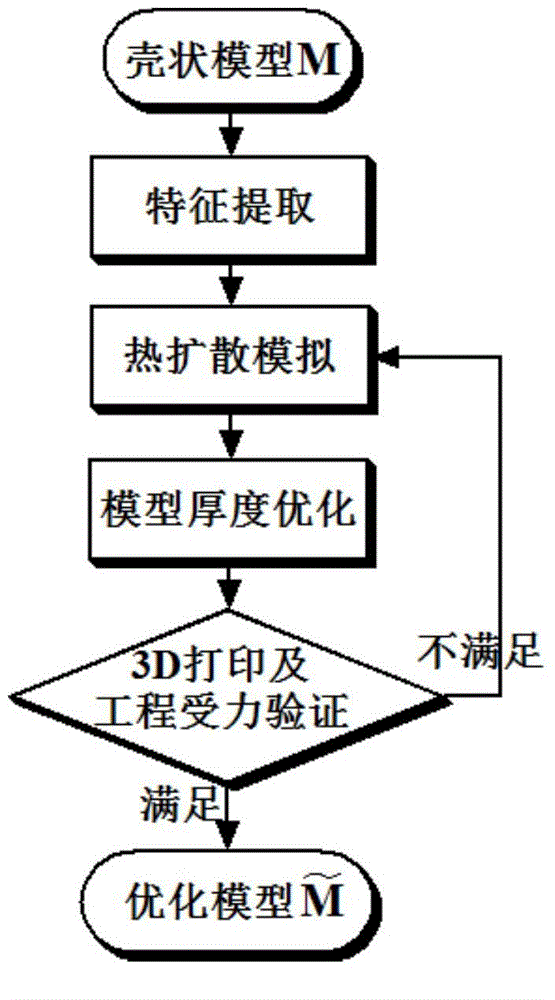

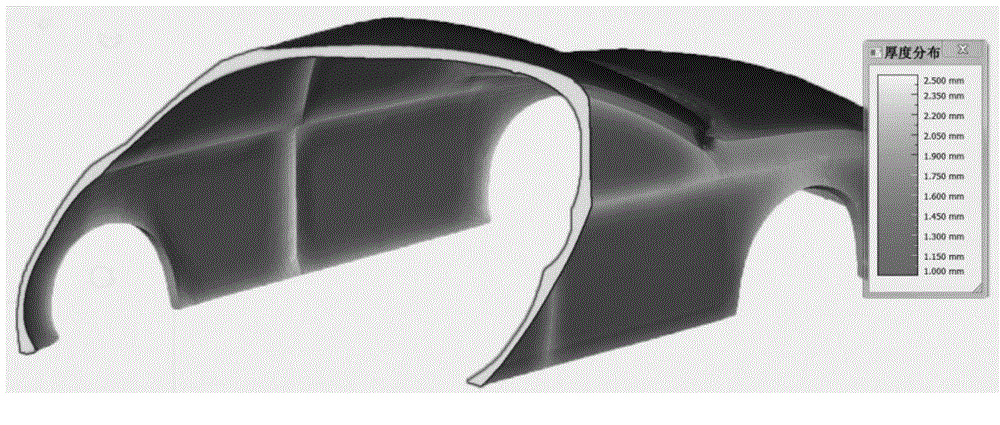

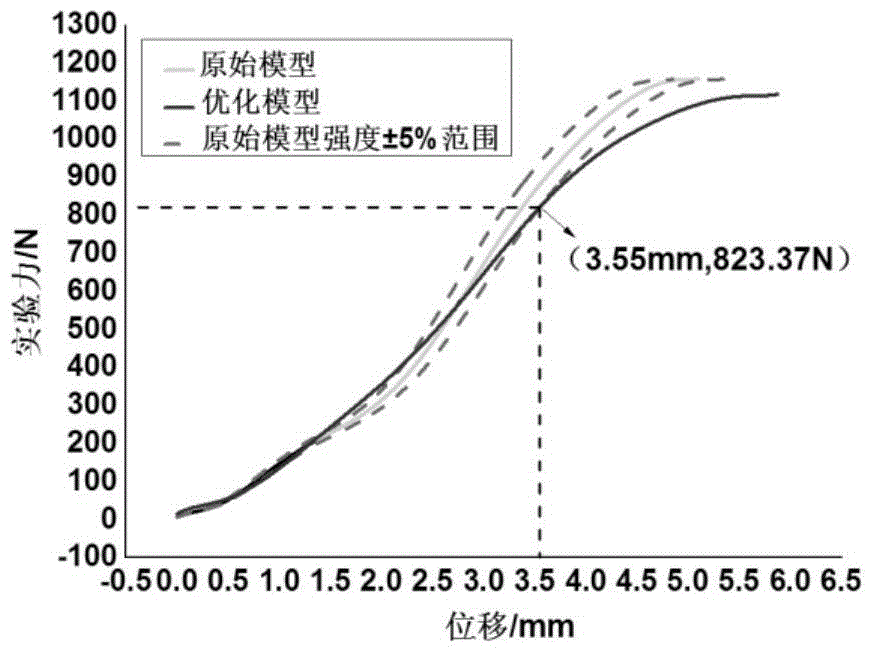

[0051] The implementation of the present invention can be divided into several main steps of feature extraction, thermal diffusion simulation and thickness optimization, 3D printing and engineering force verification:

[0052] (1) Feature extraction

[0053] Given a shell model M with thickness, S is its corresponding inner surface. First of all, it is necessary to perform feature analysis on the inner surface S of the model, which includes two parts: automatic extraction of geometric information features and interactive extraction of other features. The former is mainly used to analyze and extract the geometric features of the model itself, such as ridge features, etc.; the latter is mainly used to supplement other features of the model, such as non-geometric features such as the main supporting parts. Here, the features play a similar role as a structural skeleton, providing constraint information for the next step of optimization.

[0054] grid point v i The normal vote ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com