3D-printed manual vertebral body interior fixing device

A 3D printing and fixation device technology, applied in prosthetics, medical science, spinal implants, etc., can solve problems such as loss of intraoperative flexibility, impact on fusion, and long waiting time for patients, so as to reduce 3D printing consumables, reduce Bedridden complications and effects of saving waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

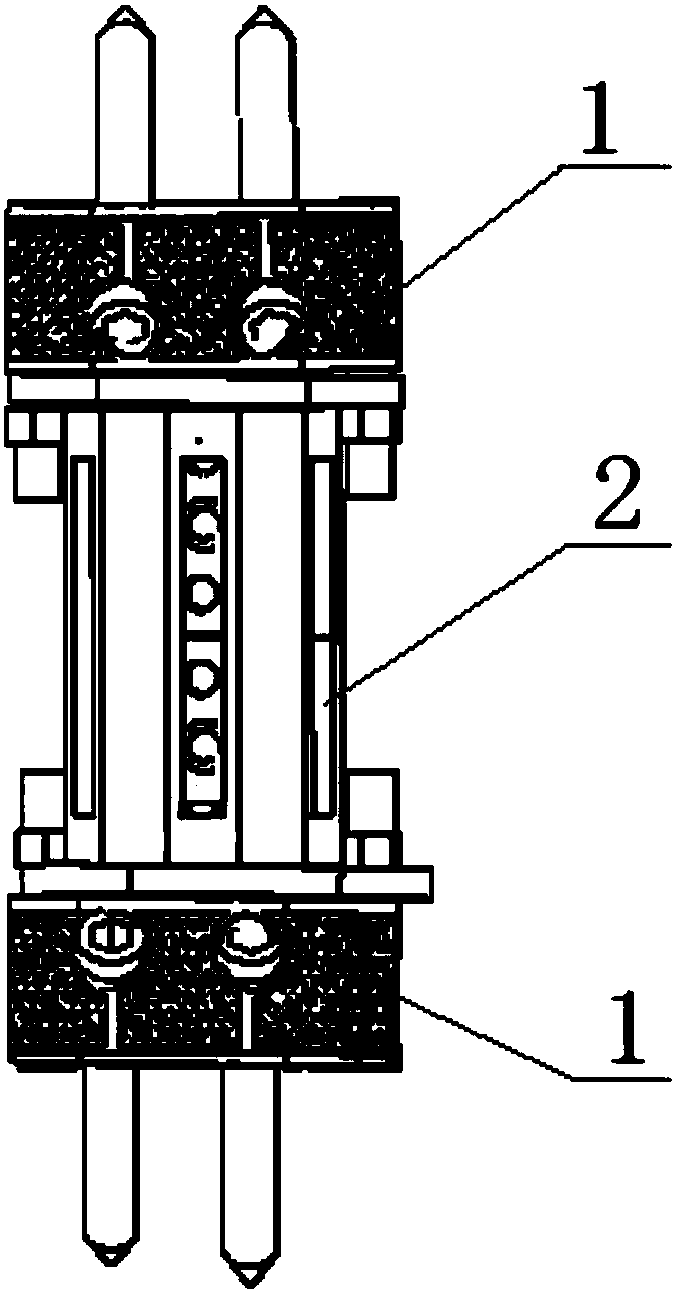

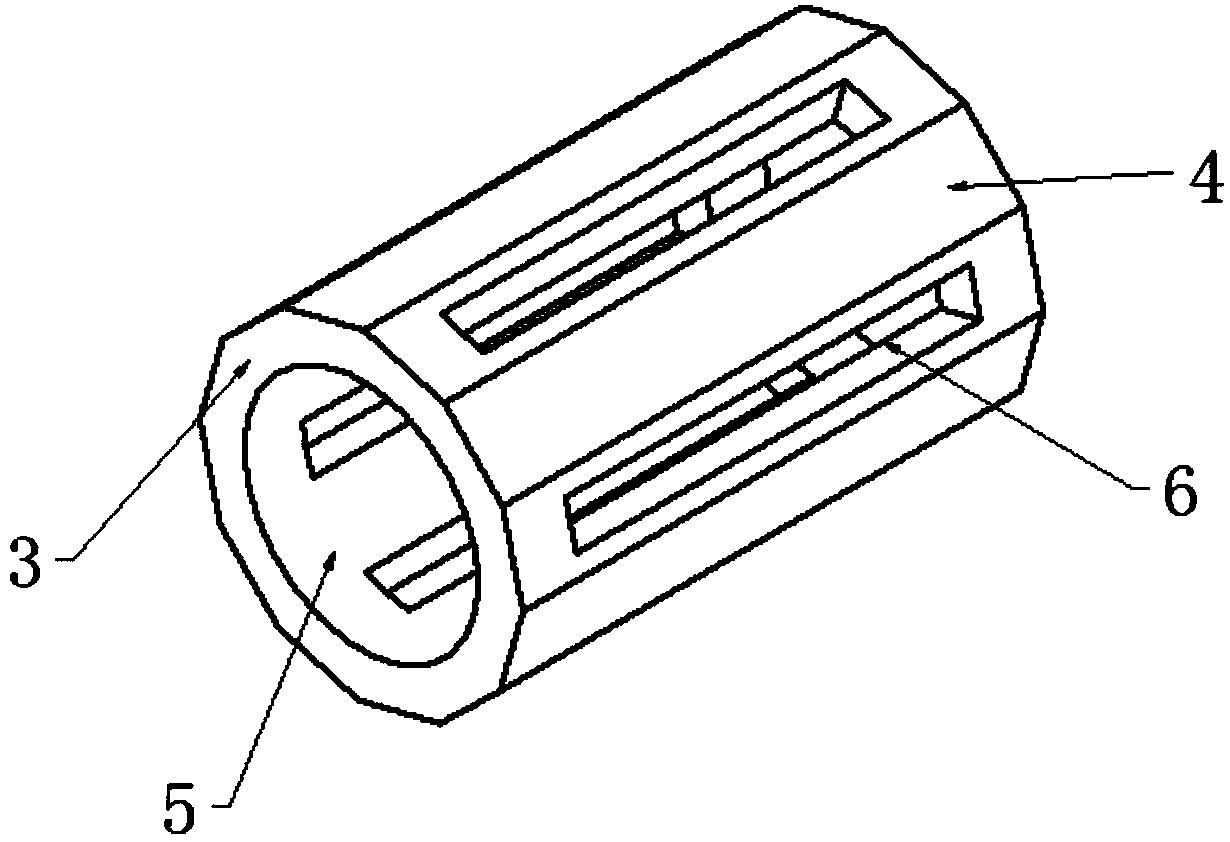

[0047] Such as figure 1 with Figure 16 As shown, the 3D printing artificial vertebral internal fixation device described in the present invention includes an extendable part 2 and 3D printing parts 1 located at both ends of the extendable part 2, as Image 6 with Figure 7 As shown, the extendable member 2 includes an outer sleeve 3 and support platforms 12 respectively located at both ends of the outer sleeve 3 , and the 3D printed part 1 is located outside the support platform 12 and is fixedly connected to the support platform 12 .

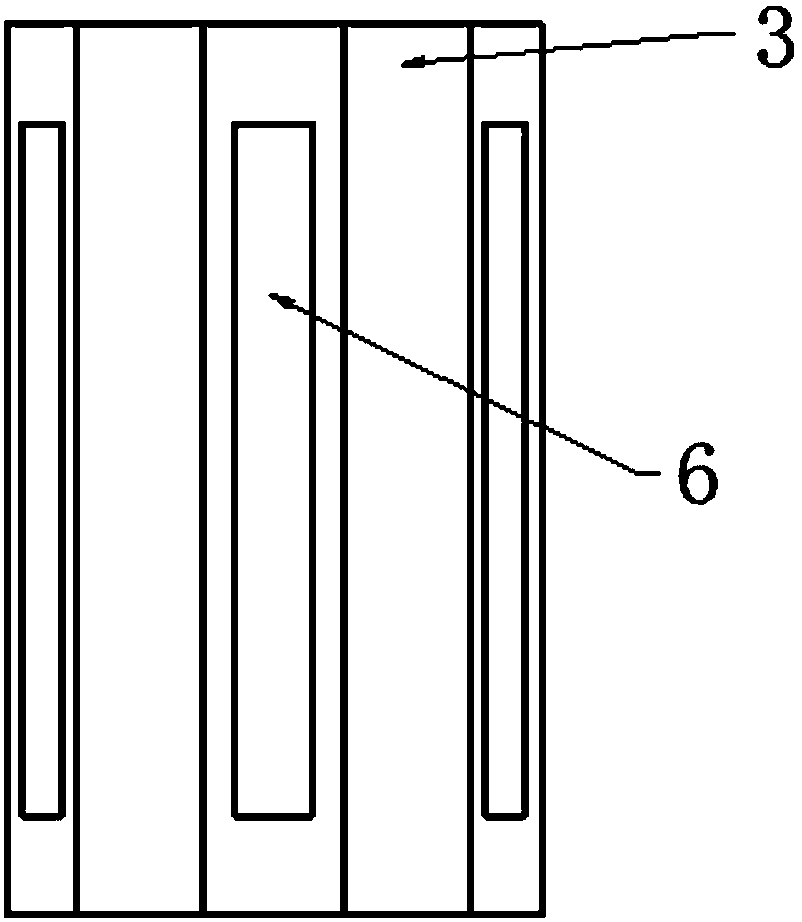

[0048] Such as figure 2 with image 3 As shown, the outer sleeve 3 is columnar, and the center of the outer sleeve 3 is provided with a cavity. In this embodiment, the cavity is cylindrical, so the tube wall of the outer sleeve 3 includes a sleeve outer wall 4 and a sleeve inner wall 5 . The outer wall 4 of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com