3D printing assisting method and device as well as 3D printer

A 3D printing and auxiliary device technology, applied in the field of printing, can solve the problems of affecting the final molding appearance, printing support structure occupying printing time, and consuming printing materials, etc., to save printing time, saving printing materials, and avoiding the effects of impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manner of the present application will be described in further detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

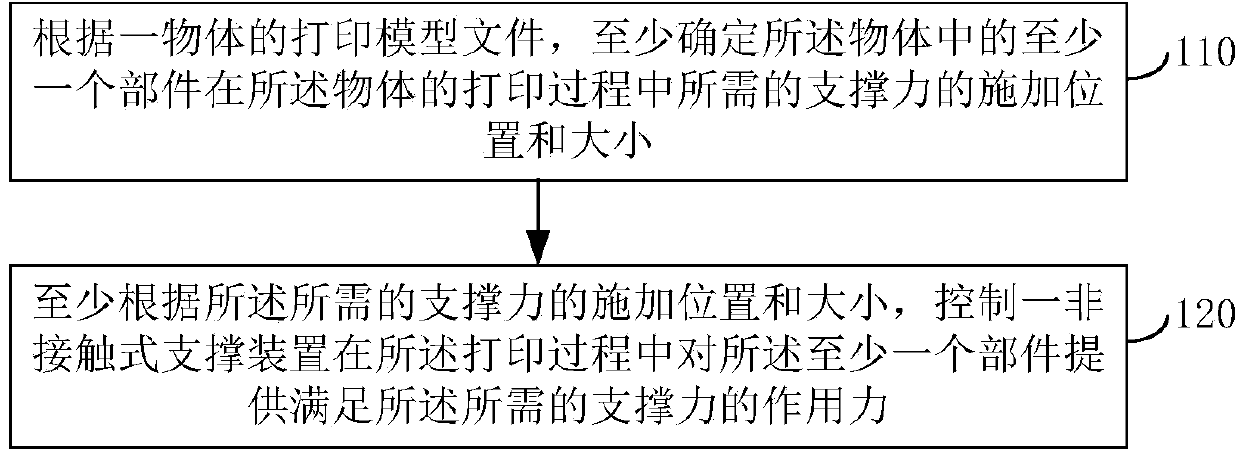

[0031] figure 1 It is a schematic flowchart of Embodiment 1 of a 3D printing auxiliary method provided by this application. Such as figure 1 As shown, this embodiment includes:

[0032] 110. According to a printing model file of an object, at least determine the application position and magnitude of the supporting force required by at least one component in the object during the printing process of the object.

[0033] For example, the 3D printing auxiliary device described in the first embodiment of the 3D printing auxiliary device provided by this application is used as the execution body of this embodiment, and steps 110-120 are performed. Wherein, the 3D printing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com