Large-section oxygen-free copper busbar and preparation method thereof

A technology of oxygen-free copper and large cross-section, which is applied in the manufacture of cables/conductors, rods/rods/wires/strip conductors, metal/alloy conductors, etc. It can solve the problems of multiple production processes, low material utilization, and low conductivity. problems, to achieve the effect of improving quality performance, excellent surface quality and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

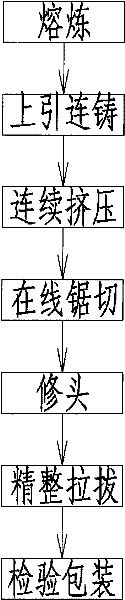

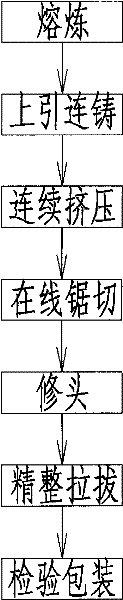

[0019] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0020] A large cross-section oxygen-free copper busbar is composed of chemical components in the following weight ratios:

[0021] Cu+Ag 99.97%, P 0.002%, Bi 0.001%, Sb 0.002%, As 0.002%, Fe 0.004%, Ni 0.002%, Pb 0.004%, Sn 0.002%, S 0.004 %, Zn is 0.003%, O is 0.001%, and the sum of impurities is 0.003%.

[0022] At 20°C, the resistivity is 0.016891Ωmm 2 / m, the conductivity is 59.2Ms / m, and the conductivity is 102.1%IACS.

[0023] Its preparation method comprises the following steps:

[0024] a. Smelting: select high-purity cathode copper with a copper-silver content of more than 99.97% as raw material, preheat and dry it, then use a vertical power frequency induction furnace to melt and keep it warm at a tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com