Method for polishing inner concave surface of optical elements as well as device

A technology for optical components and polishing devices, which is applied to optical surface grinders, grinding/polishing equipment, and polishing compositions containing abrasives, etc., which can solve the problem that the workpiece has a limited swing range, the polishing wheel cannot be inserted into the cavity, and cannot adapt to processing and other issues to achieve the effect of high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

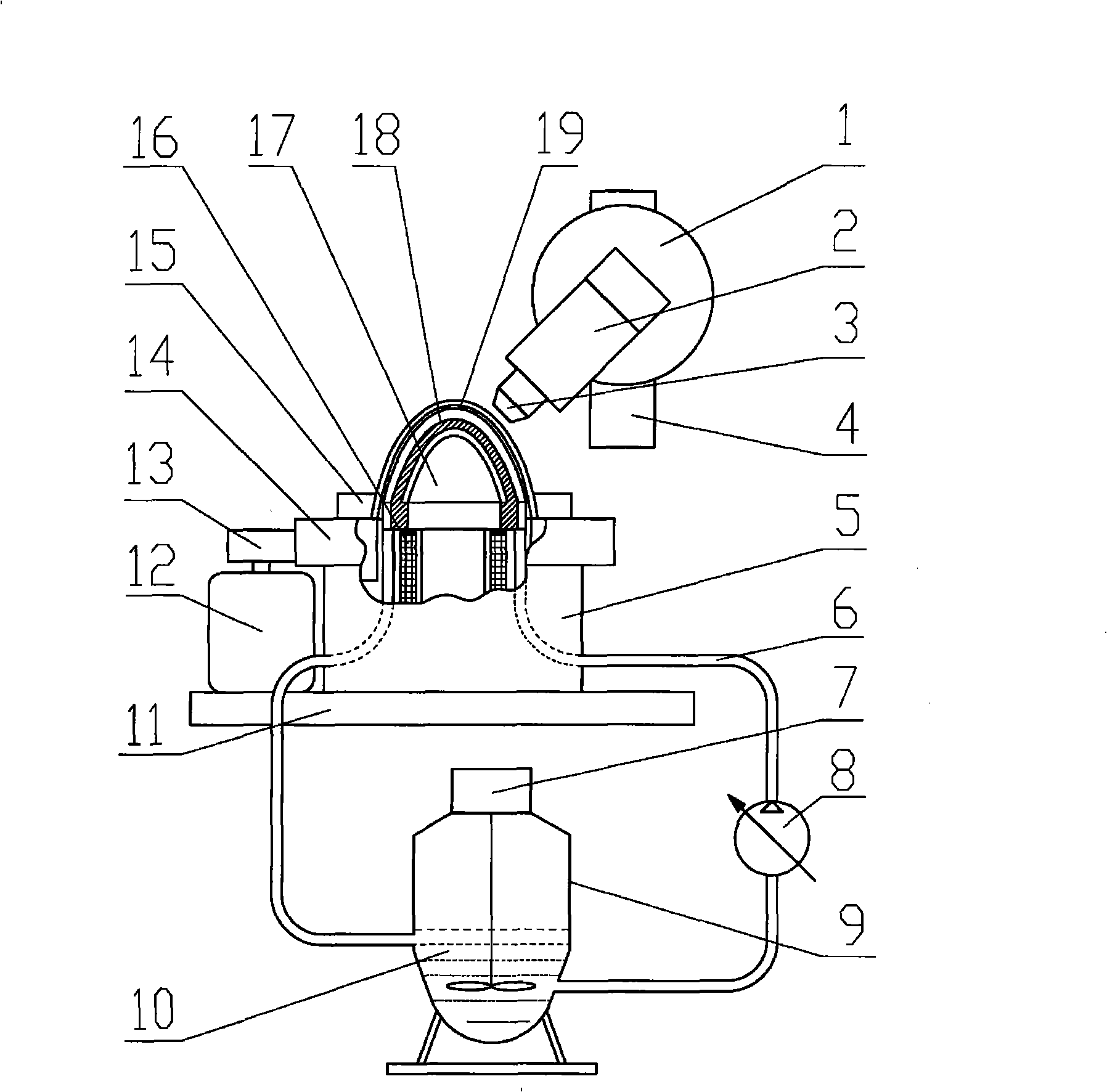

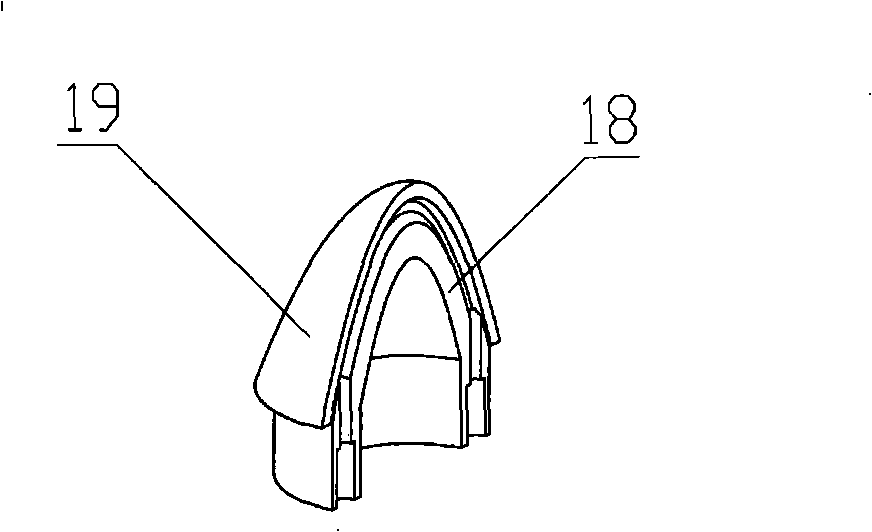

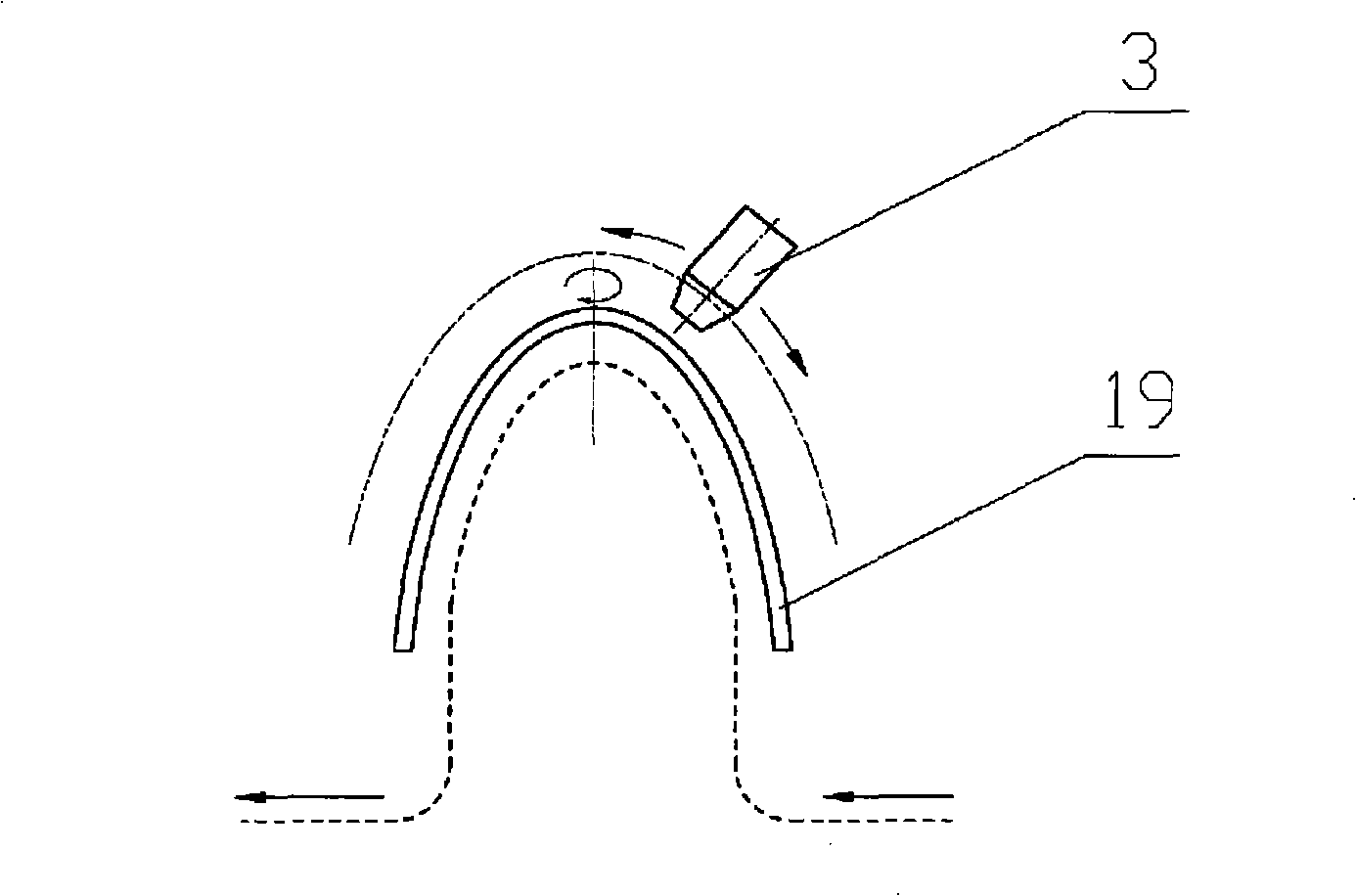

[0028] figure 1 It is a structural schematic diagram of the device of the present invention, figure 2It is a schematic diagram of the positional relationship between the slotted mandrel and the workpiece to be processed. The polishing turntable base 5 is fixedly connected with the CNC XY workbench 11, and the inner magnetic pole excitation coil 16, the inner magnetic pole core 17 and the mandrel 18 are integrally fixed on the numerical control XY workbench 11 and kept concentric with the polishing turntable base 5; 15 Fix the workpiece 19 on the polishing turntable 14, the polishing turntable 14 and the polishing turntable base 5 are connected by bearings, so that together with the workpiece 19, they rotate under the action of the turntable drive motor 12 and the transmission wheel 13, and the rotating central axis and the mandrel The axes of 18 are coincident, and keep a small gap between the inner concave surface of the workpiece 19 and the mandrel 18, and the two surfaces...

Embodiment 2

[0035] In this embodiment, the inner magnetic pole iron core 17 of the inner concave surface polishing device for optical elements adopts the form of permanent magnet instead of the inner magnetic pole excitation coil 16, and the outer magnetic pole tool head 3 also adopts the form of permanent magnet, which is changed by adjusting the distance from the magnetic pole to the processing area. magnetic field strength. The device structure and processing method of other parts are the same as those in Example 1.

Embodiment 3

[0037] In this embodiment, the outer magnetic pole tool head 3 of the optical element inner concave surface polishing device adopts a multi-pole composite magnetic pole head, and can rotate around its own central axis to form a rotating external strengthening magnetic field. The device structure and processing method of other parts are the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com