Production technique of pure cotton non-woven fabrics and device

A production process and non-woven technology, applied in non-woven fabrics, textiles and papermaking, etc., can solve the problems of complex process, low production rate and high energy consumption of pure cotton non-woven fabrics, saving raw materials and manufacturing costs. Low, reduced maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

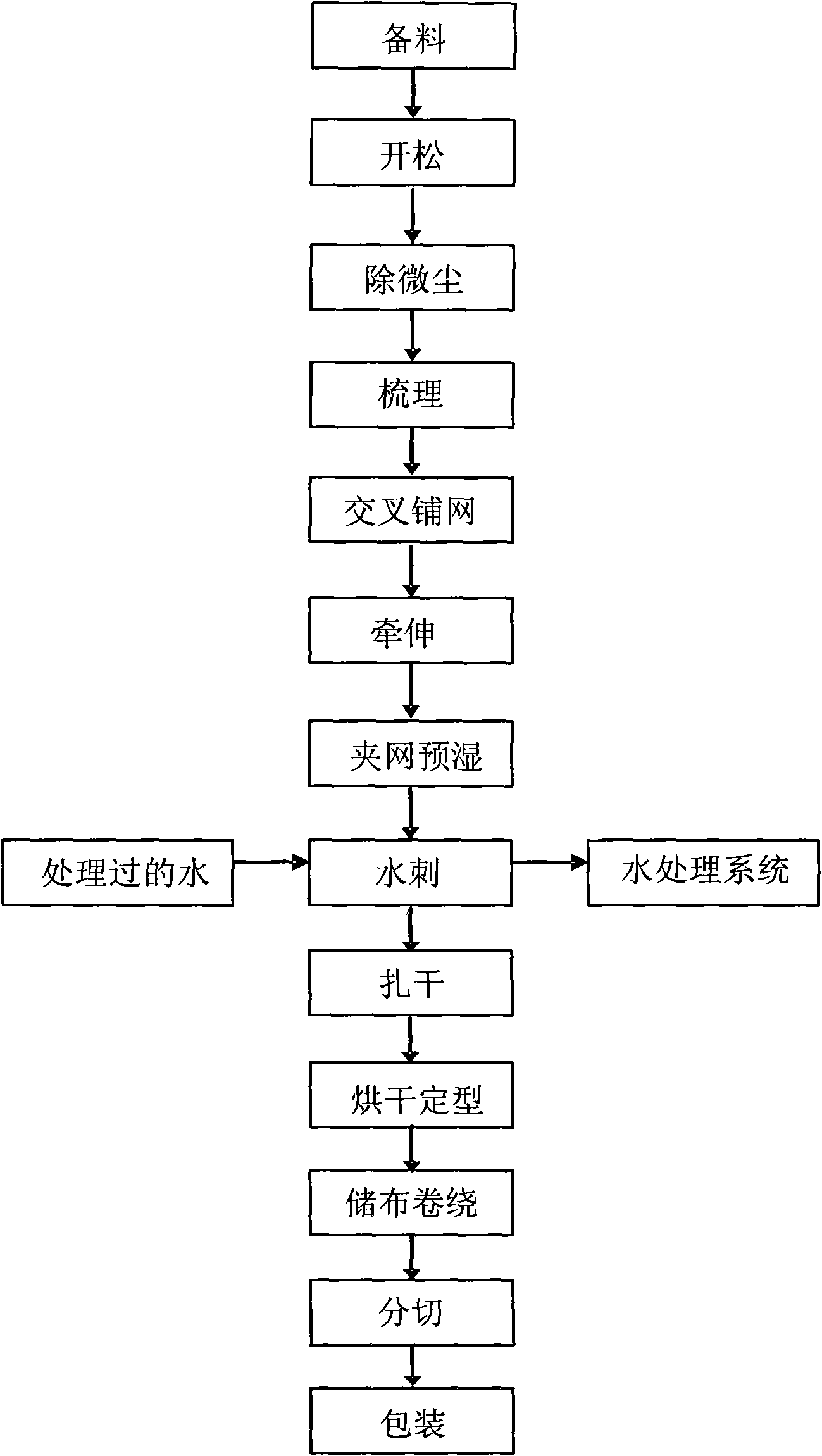

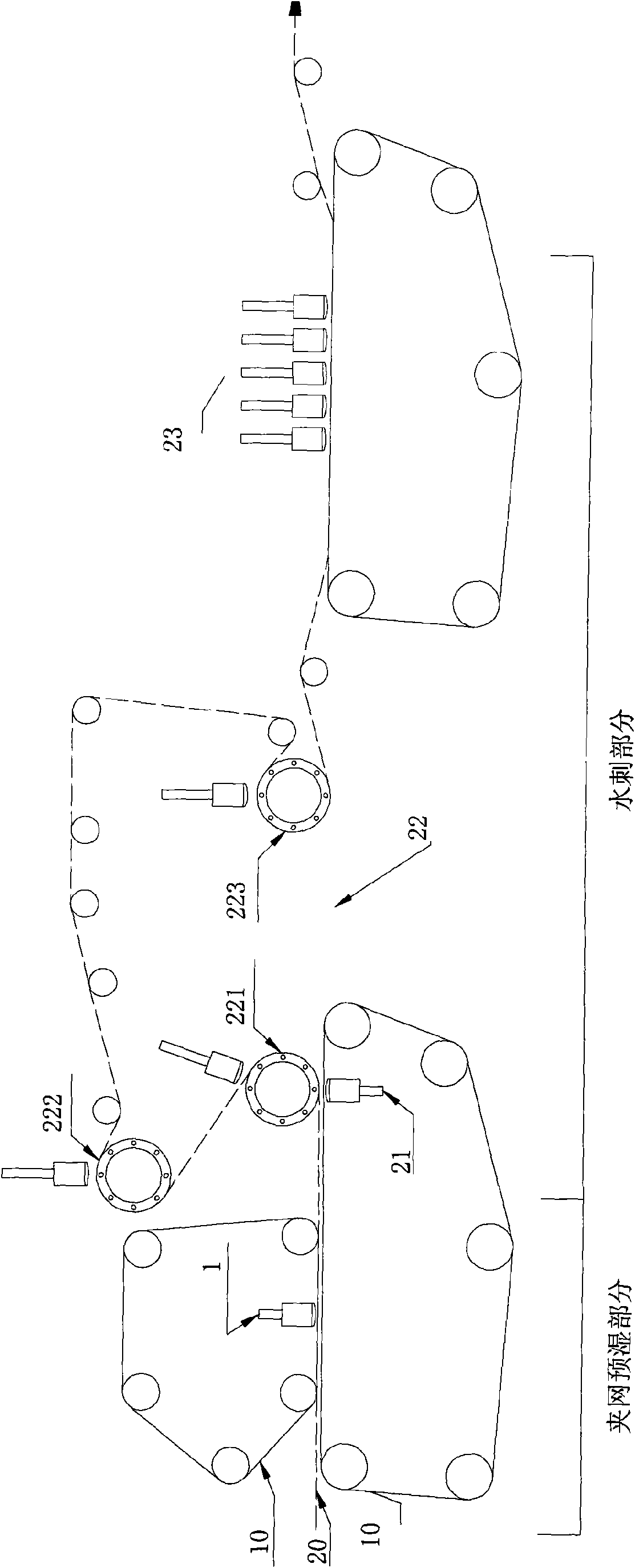

[0030] Such as figure 1 As shown, the non-woven fabric production process sequence in this example includes the following steps: material preparation, opening, dust removal, carding, cross-lapping, drafting, pre-wetting of the sandwich, spunlace, drying, drying and setting, storage Cloth winding, cutting, packaging.

[0031] 1) Material preparation: Prepare high-quality absorbent cotton or colored cotton for use in the next process.

[0032] 2) Opening: Use an opening device to open the raw material into a single fiber state. The prepared absorbent cotton or colored cotton is sent to the pre-opener through the conveyor belt for preliminary opening, and then sent to the large warehouse blender through the cotton conveying fan to fully mix various fibers of different lengths and deniers. Part of the raw material is taken out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com