Processing method and device for forming aspheric surface part by numerical control tangent line turning method

A processing method and forming processing technology, applied in the field of NC tangential rotary forming processing and devices for aspheric parts, can solve the difficult processing quality requirements of aspheric optical parts, low processing efficiency, and inability to adapt to multi-variety batch-variable batch processing requirements, etc. problems, achieve the effect of ensuring roughness and surface quality requirements, improving processing efficiency, and simple and easy operation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

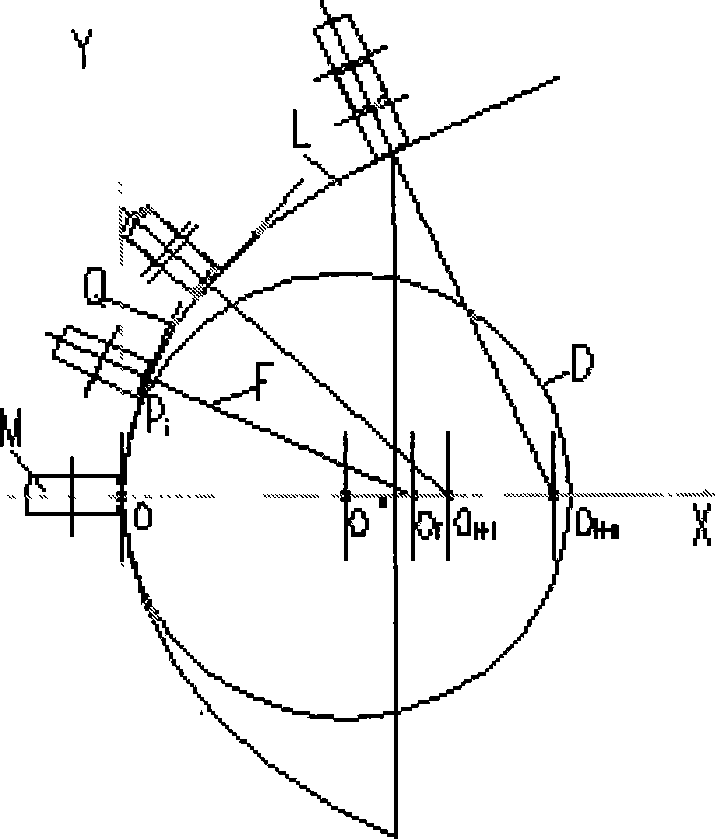

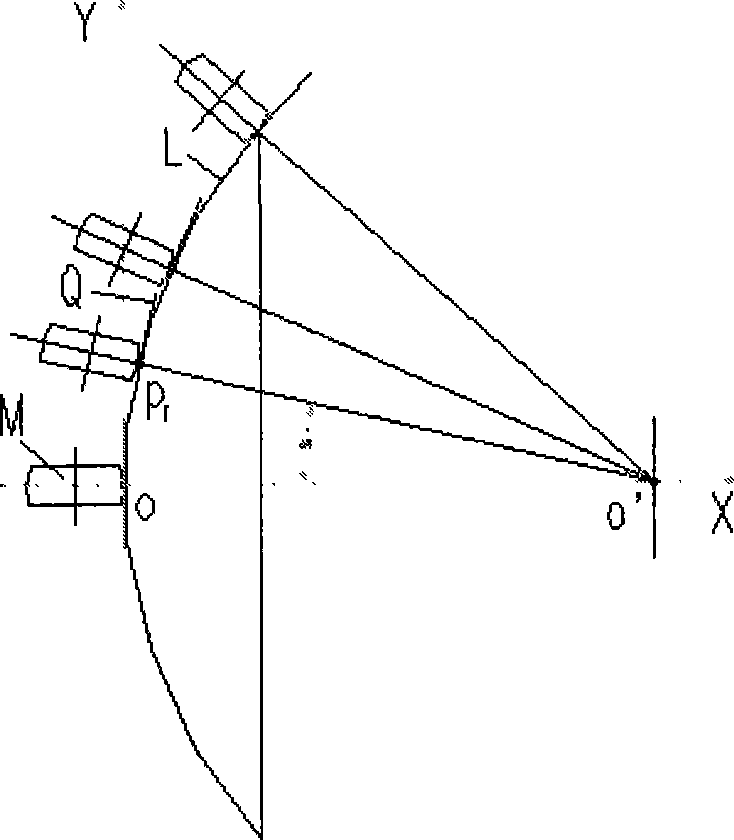

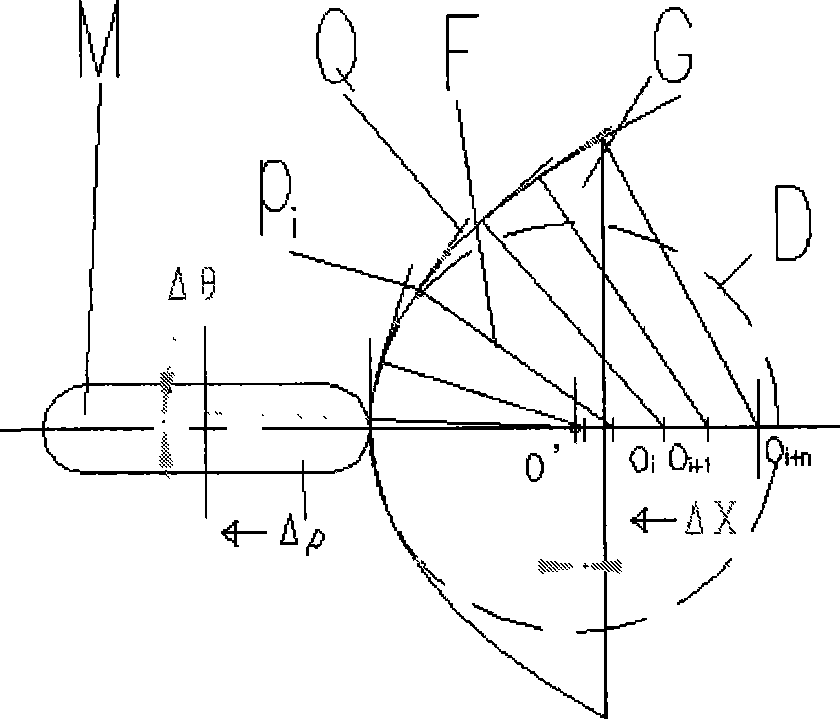

[0034] figure 1 Shown are the properties of the curves (higher or quadratic curves) on the aspheric meridional profile. In the figure, L is the design of any given aspheric meridional profile curve, O is the vertex of the surface, P i is any tangent point on the curve L, O’ is the curvature center of the vertex circle, O i is the intersection point of the normal line and the weighing axis OX, Q is the tangent point P i on the tangent line, F is the tangent point P i to intersection O i The normal line, D is the vertex circle of the curve, and M is the grinding wheel.

[0035] Depend on figure 1 It can be seen that there is only one axis of symmetry OX on the curved surface of an axisymmetric aspheric part, and each tangent point P on all aspheric meridional profile curves i The normal to the axis of symmetry has a different intersection position O i , all intersections form a continuous normal distance O’O i+n , and the normal length P of all intersection points to tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com