Nanopowder laser selective melting additive manufacturing system and method

An additive manufacturing and nano-powder technology, applied in the field of nano-powder laser selective melting additive manufacturing system, can solve problems such as difficult to manufacture parts, and achieve the effect of improving selective laser sintering performance and surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

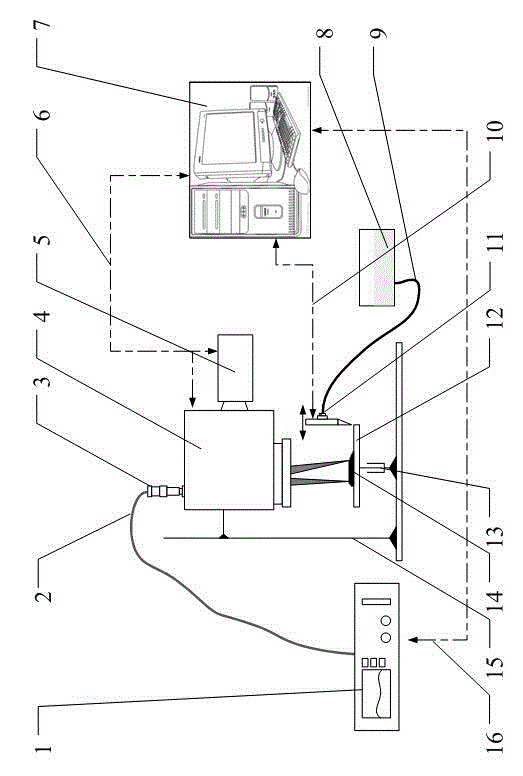

[0025] Specific implementation mode one: as figure 1 As shown, the nano powder laser selective melting additive manufacturing system provided in this embodiment consists of a single-mode fiber laser 1, an output fiber 2, a QBH connector 3, a scanning galvanometer 4, a CCD camera 5, a scanning control line 6, and a control computer 7 , coating chamber 8, conveying pipeline 9, coating motion control device 10, coating knife 11, worktable base 12, lifting device 13, parts 14, bracket 15, and laser control line 16.

[0026] The support 15 is provided with a scanning vibrating mirror 4 and a lifting device 13 , the worktable base 12 is installed on the lifting device 13 , and the scanning vibrating mirror 4 is located above the working table base 12 . The single-mode fiber laser 1 outputs a single-mode Gaussian laser beam with a beam quality less than 1.05, which is connected to the scanning galvanometer 4 through the output fiber 2 and the QBH connector 3, and a CCD camera 5 is us...

specific Embodiment approach 2

[0028] Specific implementation mode 2: In this implementation mode, 100nm copper nanopowder, ethylene glycol, PVP (polyvinylpyrrolidone k30), and deionized water are used to mix and prepare a dispersion in a certain proportion, and the additive manufacturing system is selectively melted by nanopowder laser The coating device coats the surface of the superalloy, in the air environment, using a 1064nm wavelength laser with a power density of 23.1W / mm 2 , scanning speed 20mm / s process parameters for scanning. Copper surface coatings can be produced on superalloys to increase surface functionality and improve quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com