Battery powder material surface treatment device and method

A technology for surface treatment devices and powder materials, which is applied in the direction of preliminary treatment to promote the drying of solid materials, heating to dry solid materials, heating devices, etc., which can solve the problems of reducing the quality of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

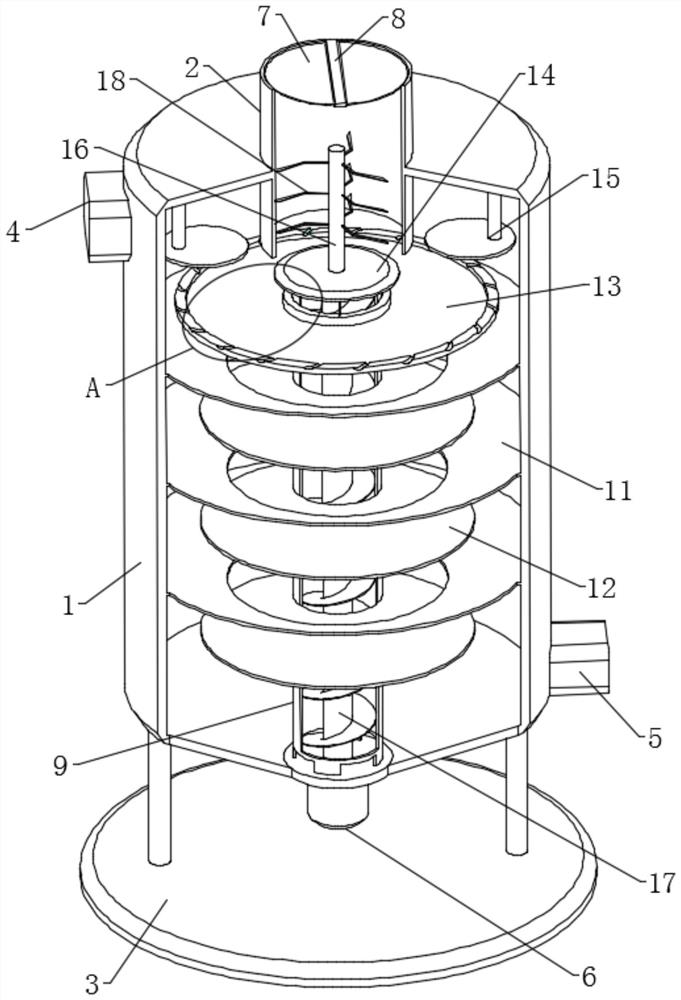

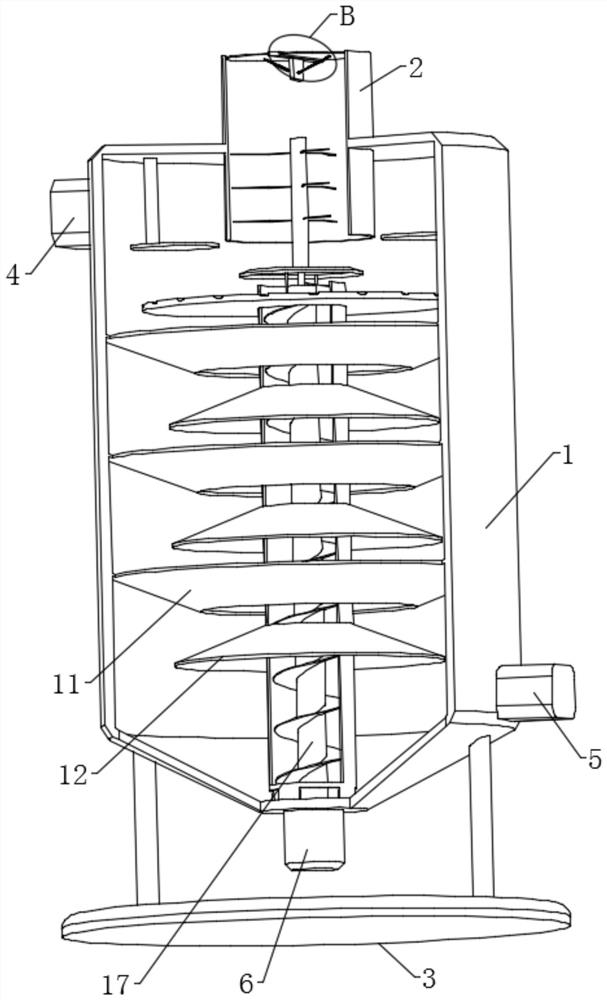

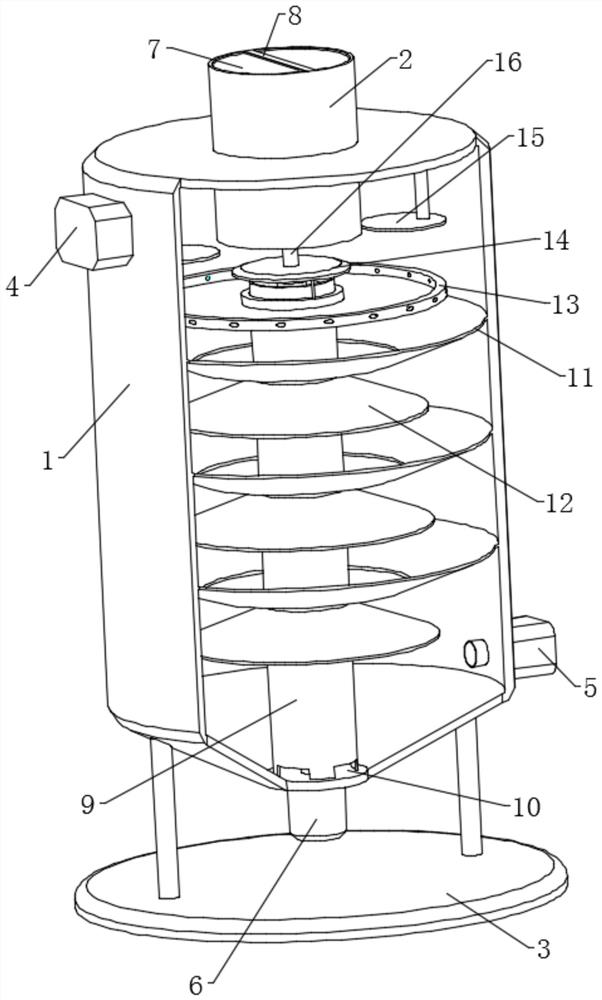

[0034] like Figure 1-7 As shown in the figure, a battery powder material surface treatment device and method proposed by the present invention includes a drying box 1 and two electric heating plates 15 , a base 3 is installed outside the drying box 1, and a fixed Drum 9, the inside of the drying box 1 is rotatably connected with a screw conveying rod 17, the outside of the drying box 1 is installed with a feeding pipe 2, the outside of the feeding pipe 2 is provided with an opening and closing mechanism, and the inside of the feeding pipe 2 is provided with a pulverizing mechanism ;

[0035] A plurality of outer ring guide plates 11 are installed inside the drying box 1, a plurality of inner ring guide plates 12 are installed outside the fixed cylinder 9, and a powder extractor 5 is installed outside the drying box 1, and the external movement of the fixed cylinder 9 is useful. For the scattering mechanism for dispersing the battery powder, the outer ring guide plate 11 and ...

Embodiment 2

[0040] like Figure 1-7 As shown, based on the first embodiment, the crushing mechanism includes a drive shaft 16 arranged inside the feed pipe 2 , a plurality of sets of cutting blades 18 are installed on the outside of the drive shaft 16 , and between the drive shaft 16 and the outside of the positioning plate 14 Connected through the transmission, the feed pipe 2 is communicated with the interior of the drying box 1;

[0041] The opening and closing mechanism includes a fixed beam 8 installed inside the feed pipe 2, the outside of the fixed beam 8 is symmetrically connected with the opening and closing plate 7, the outside of the fixed beam 8 is installed with a fixed plate 21, and the outside of the opening and closing plate 7 is installed with a spring 22, One end of the spring 22 away from the hinge plate 7 is connected to the outside of the fixing plate 21 .

[0042] In this embodiment, during operation, the screw conveying rod 17 makes the drive shaft 16 start to rota...

Embodiment 3

[0046] like Figure 1-7 As shown, based on the above-mentioned first or second embodiment, a plurality of discharge grooves 19 are provided on the outside of the holding plate 13, the cross-section of the discharge grooves 19 is arc-shaped, and the two electric heating plates 15 are installed inside the drying box 1;

[0047] A heat storage pipe 23 is installed inside the drying box 1, a heat transfer pipe 24 is installed outside the outer guide plate 11, a heat transfer pipe 25 is installed inside the inner guide plate 12, and the heating end of the electric heater 4 is connected to the heat storage pipe 23. The interior is communicated, and the heat storage tube 23 and the heat transfer tube 24 communicate with each other.

[0048] In this embodiment, when working, the electric heater 4 is started, and the electric heater 4 starts to heat the heat storage pipe 23 inside the drying box 1, and the heat storage pipe 23 is communicated with the heat conduction pipe 24, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com