Rapid micro-nano reconstruction treatment method for copper metal and application of rapid micro-nano reconstruction treatment method

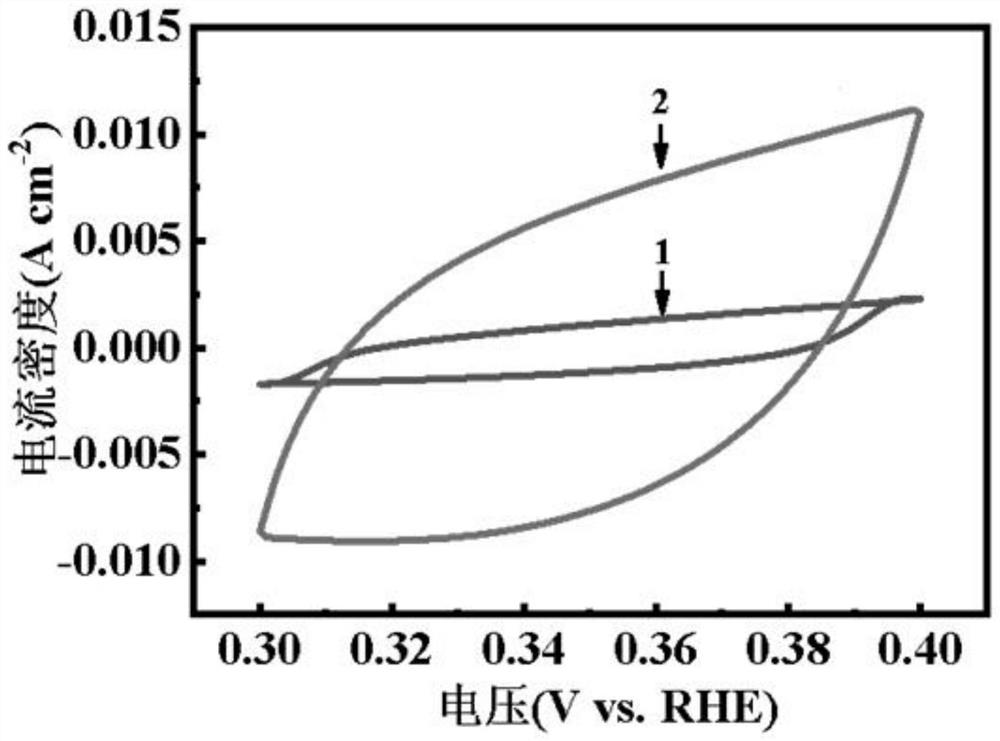

A processing method, micro-nano technology, applied in electrolysis components, electrodes, electrolysis process, etc., can solve the problems of low roughness and small specific surface area of commercial copper metal, achieve simple process, low equipment requirements, increase specific surface area and The effect of roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0032] Specific implementation mode 1: In this implementation mode, the rapid micro-nano reconstruction processing method of copper metal is implemented according to the following steps:

[0033] 1. Use copper or copper-based alloy metal materials as the precursor;

[0034] 2. With water as the solvent, the solute concentration is 0.5~5mol L -1 of (NH 4 ) 2 S 2 O 8 and 5~10mol L -1 NaOH, prepared to obtain a mixed oxidation solution;

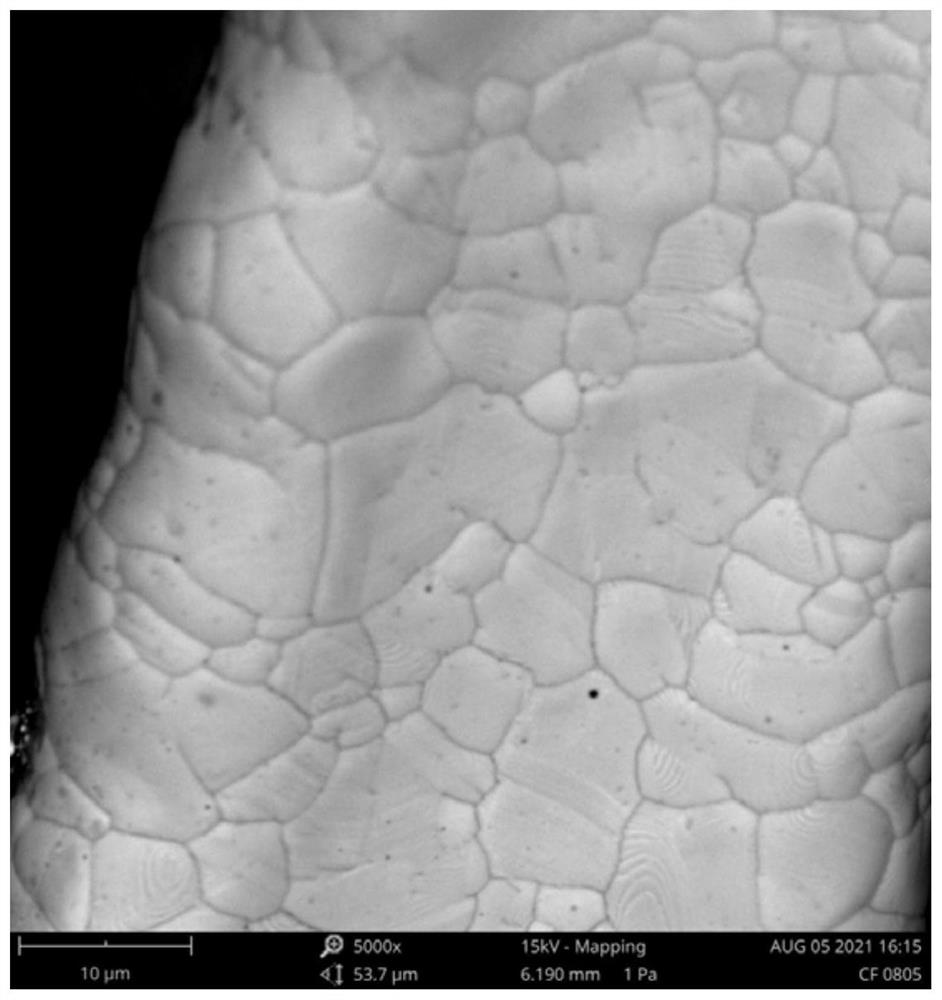

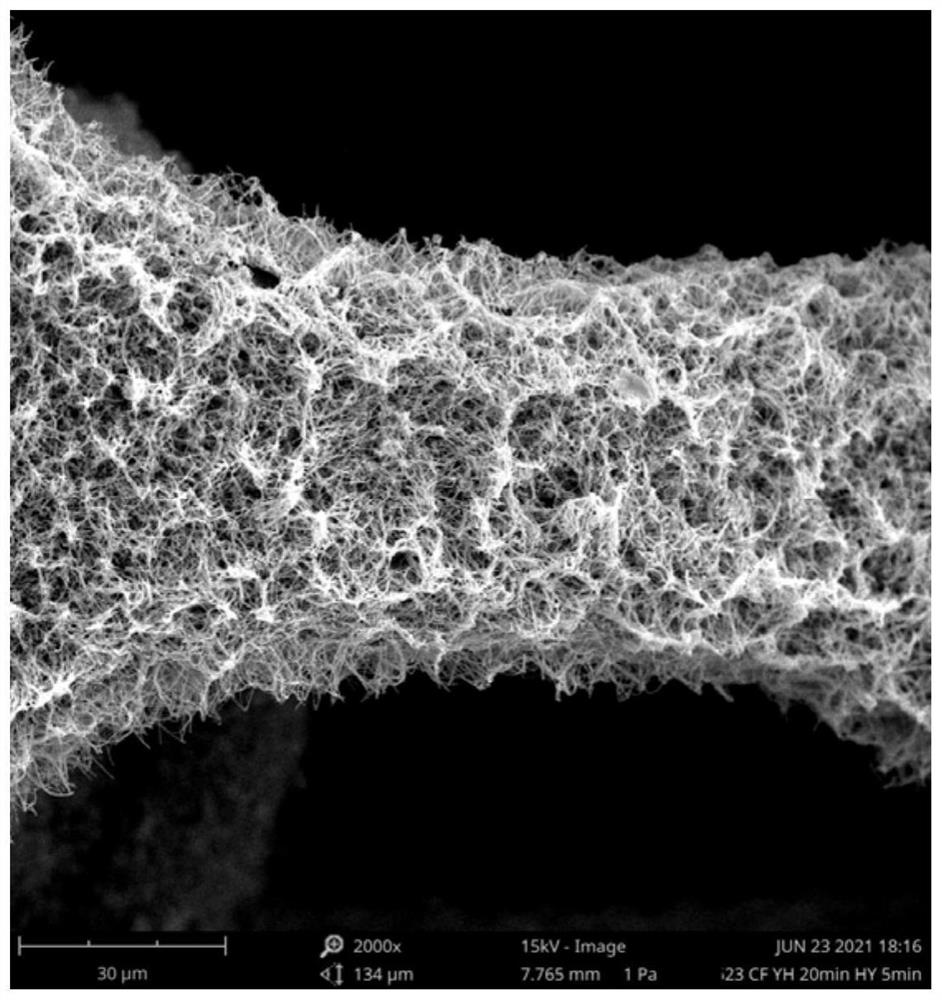

[0035] 3. Put the metal material precursor in step 1 into a mixed oxidation solution for oxidation treatment, and obtain a metal oxide precursor with a micro-nano porous fiber structure after cleaning and drying;

[0036] 4. With water as the solvent, the solute includes 50-100g L -1 Dimethylamine borane (DMAB) and 10~50g L -1 NaOH, prepared to obtain a mixed reducing solution;

[0037] 5. The metal oxide precursor in step 3 is placed in a mixed reducing solution for reduction treatment to obtain a metal material with a micro-nano porou...

specific Embodiment approach 2

[0040] Embodiment 2: This embodiment is different from Embodiment 1 in that the copper-based alloy is brass, bronze, white copper or phosphor bronze.

specific Embodiment approach 3

[0041]Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the form of the metal material in Step 1 is powder, metal wire, metal sheet or metal film.

[0042] In this embodiment, the metal material can also be a prepared copper metal device, and a two-step solution processing method is used to realize the preparation of micro-nano fiber structure on the surface of the complex copper device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com