Method for preparing composite nano film on metal surface

A metal surface and nano-film technology, applied in the direction of electrolytic organic material coating, etc., to achieve high compactness, high stability, and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Prepare the base metal of composite nano film on its surface to be the aluminum alloy of designation 5052, and size is 50 * 30 * 0.2 (mm), and its concrete method comprises the following steps:

[0034] 1) Preparation of first layer electrolytic polymerization polymer nano film:

[0035] a. First, clean the aluminum alloy of grade 5052:

[0036] Use acetone to ultrasonically wash the base metal for 10nm, and after drying at room temperature, degrease and decontaminate the metal surface with 10% SK-144 alkali solution at 60°C, then rinse repeatedly with clean water, and use it as a working electrode after drying at room temperature;

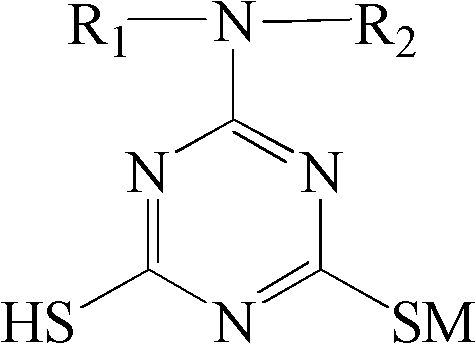

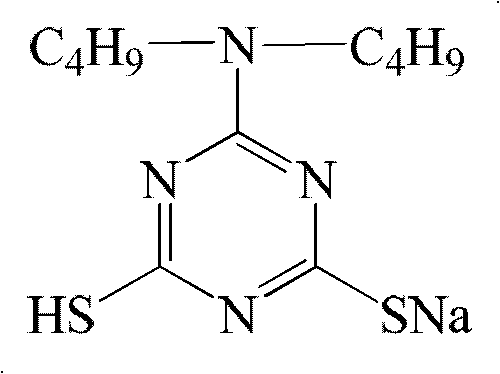

[0037]B, with the metal surface after cleaning as working electrode, with SUS304 electrode as auxiliary electrode, saturated calomel electrode as reference electrode, to contain 2.0mmol / L triazine thiol monosalt compound and 0.1mol / L sodium nitrite ( As a supporting electrolyte), the mixed solution is an electrolyte solution, and the elect...

Embodiment 2

[0044] Prepare the base metal of composite nano film on its surface to be the aluminum alloy of designation 5052, and size is 50 * 30 * 0.2 (mm), and its concrete method comprises the following steps:

[0045] 1) Preparation of first layer electrolytic polymerization polymer nano film:

[0046] a. First, clean the aluminum alloy of grade 5052:

[0047] Use acetone to ultrasonically wash the base metal for 5nm, dry it at room temperature, degrease the metal surface with 10% SK-144 alkali solution at 80°C, rinse it repeatedly with clean water, dry it at room temperature and use it as a working electrode;

[0048] B, with the metal surface after cleaning as working electrode, with SUS304 electrode as auxiliary electrode, saturated calomel electrode as reference electrode, to contain 3.0mmol / L triazine thiol monosalt compound and 0.5mol / L sodium sulfite (as support The mixed solution of electrolyte) is the electrolyte solution, and the constant current method is used for electrol...

Embodiment 3

[0055] Prepare the base metal of composite nano film on its surface to be the steel sheet of grade 304, and size is 50 * 30 * 0.2 (mm), and its concrete method comprises the following steps:

[0056] 1) Preparation of first layer electrolytic polymerization polymer nano film:

[0057] a. First, clean the steel sheet of grade 304:

[0058] Use acetone to ultrasonically wash the base metal for 15nm, dry it at room temperature, degrease the metal surface with 10% SK-144 alkali solution at 75°C, rinse it repeatedly with clean water, dry it at room temperature and use it as a working electrode;

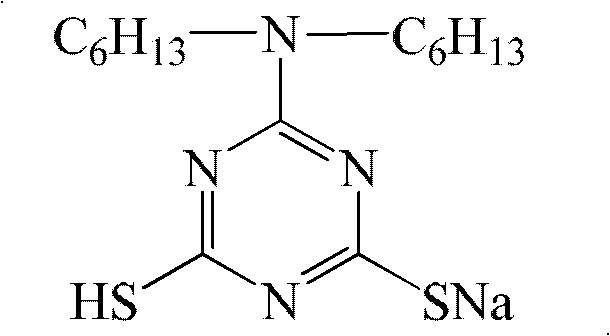

[0059] B, with the metal surface after cleaning as working electrode, with Pt electrode as auxiliary electrode, saturated calomel electrode is reference electrode, to comprise 3.0mmol / L triazine mercaptan monosalt compound and 0.1mol / L sodium carbonate (as The mixed solution of supporting electrolyte) is the electrolyte solution, and the electrolysis is carried out by constant current met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com