End milling cutter for processing nonferrous metal

A non-ferrous metal and end mill technology, applied in the field of metal cutting, can solve problems such as affecting the appearance and surface quality of non-ferrous metal products, no trimming of the cutting part, anti-vibration structure, and inability to perform surface treatment, so as to reduce residues Depth, improve surface quality, prevent resonance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

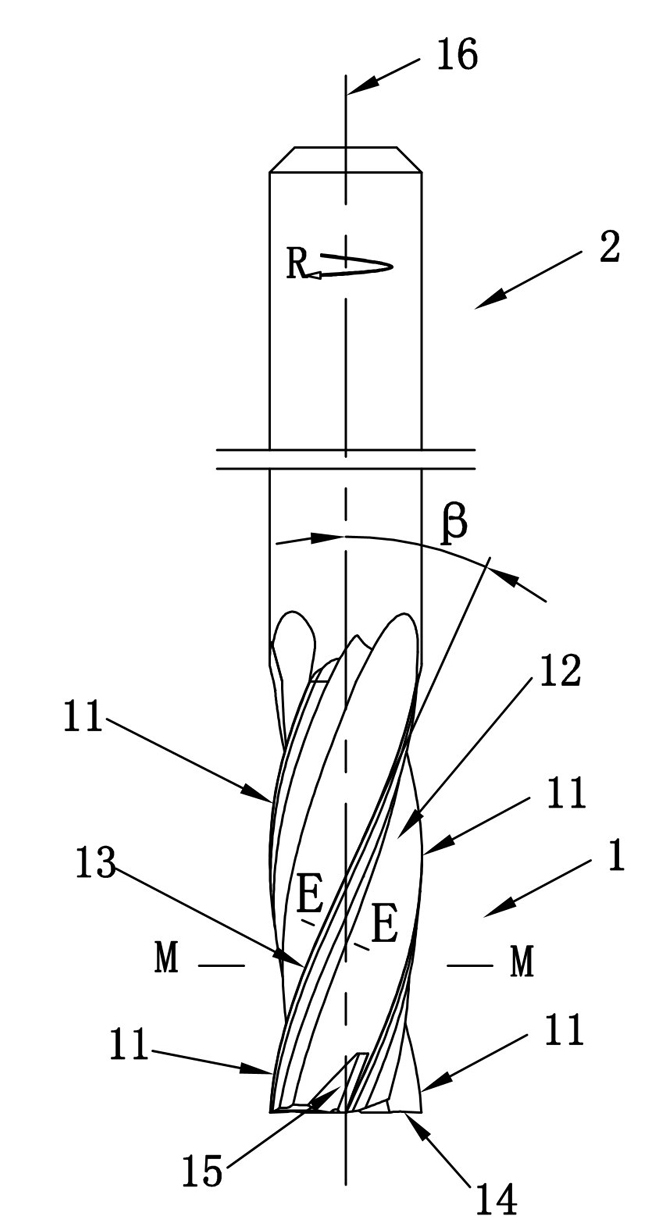

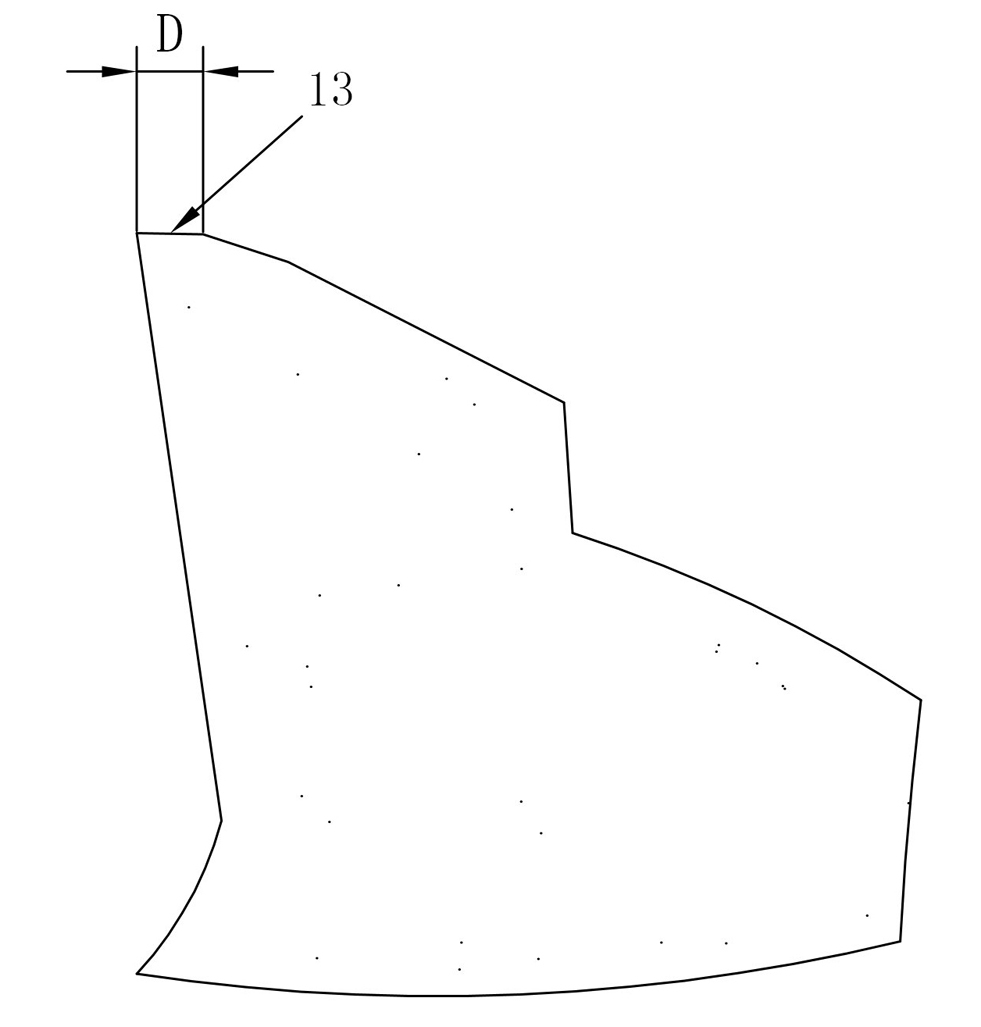

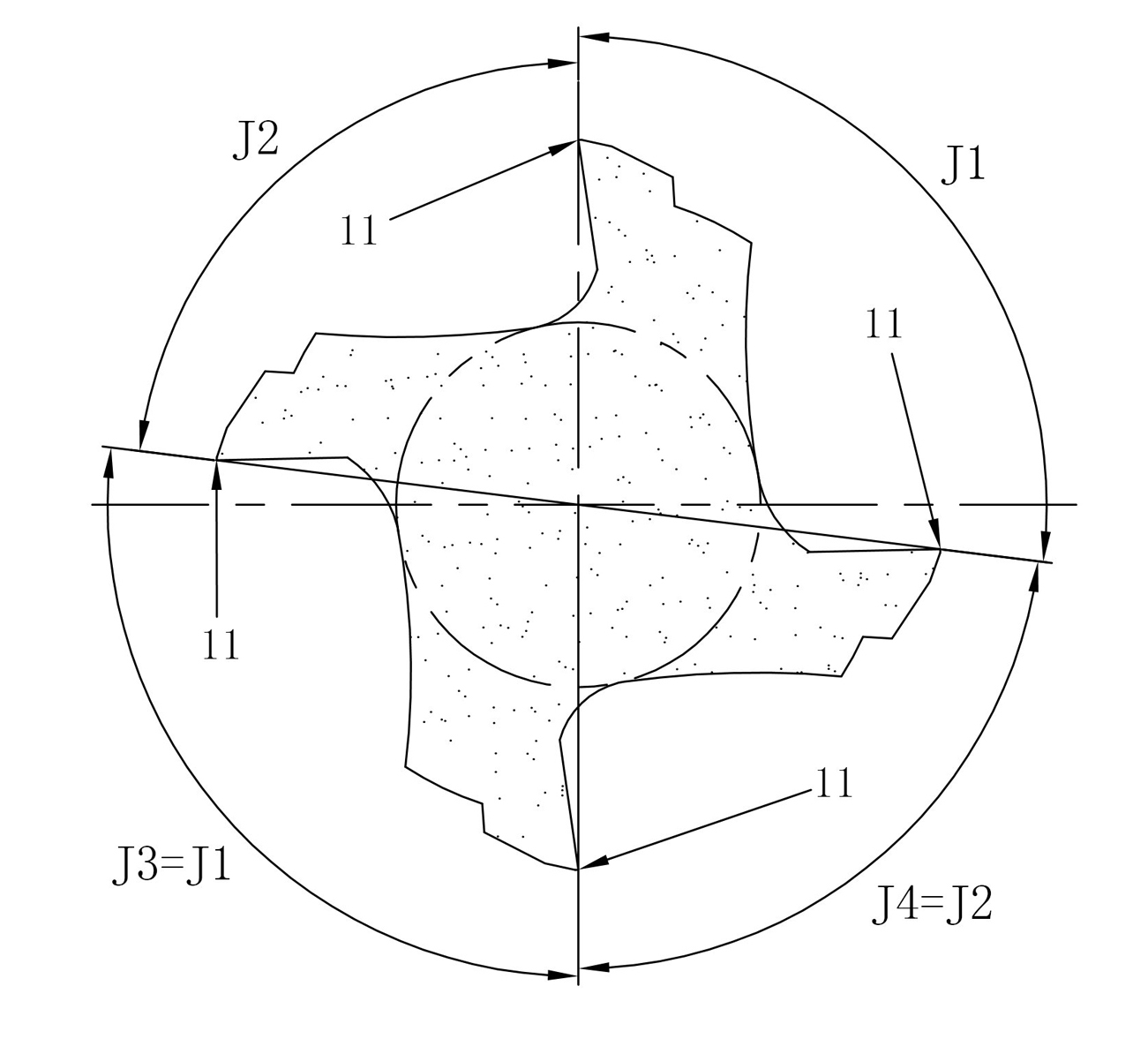

[0021] Figure 1 to Figure 5 An embodiment of an end milling cutter for non-ferrous metal processing of the present invention is shown, which is made of cemented carbide material into a cylinder, including a cutting part 1 and a shank part 2, wherein the shank part 2 is located at the rear end , used to fix the end mill on the machine tool, and the cutting part 1 is located at the front end for cutting. The entire cutting part 1 is provided with a plurality of peripheral cutting edges 11 (four in this embodiment) extending helically from the bottom end to the shank part 2. Each peripheral cutting edge 11 takes the central axis 16 as the center of rotation and rotates in the direction of rotation of the end mill. R is twisted into a spiral shape, and a spiral chip removal groove 12 is provided between two adjacent peripheral edges 11. In the radial plane of the cutting part 1, the line connecting each peripheral edge 11 to the rotation center of the end mill is the same as the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com