Photochromic films and method for manufacturing the same

一种光致变色膜、光致变色的技术,应用在化学仪器和方法、光学、光学元件等方向,能够解决形成皱纹表面、差透明性、很难达到均匀的厚度等问题,达到优异透明度和耐久性、膜表面缺陷小、厚度偏差小的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

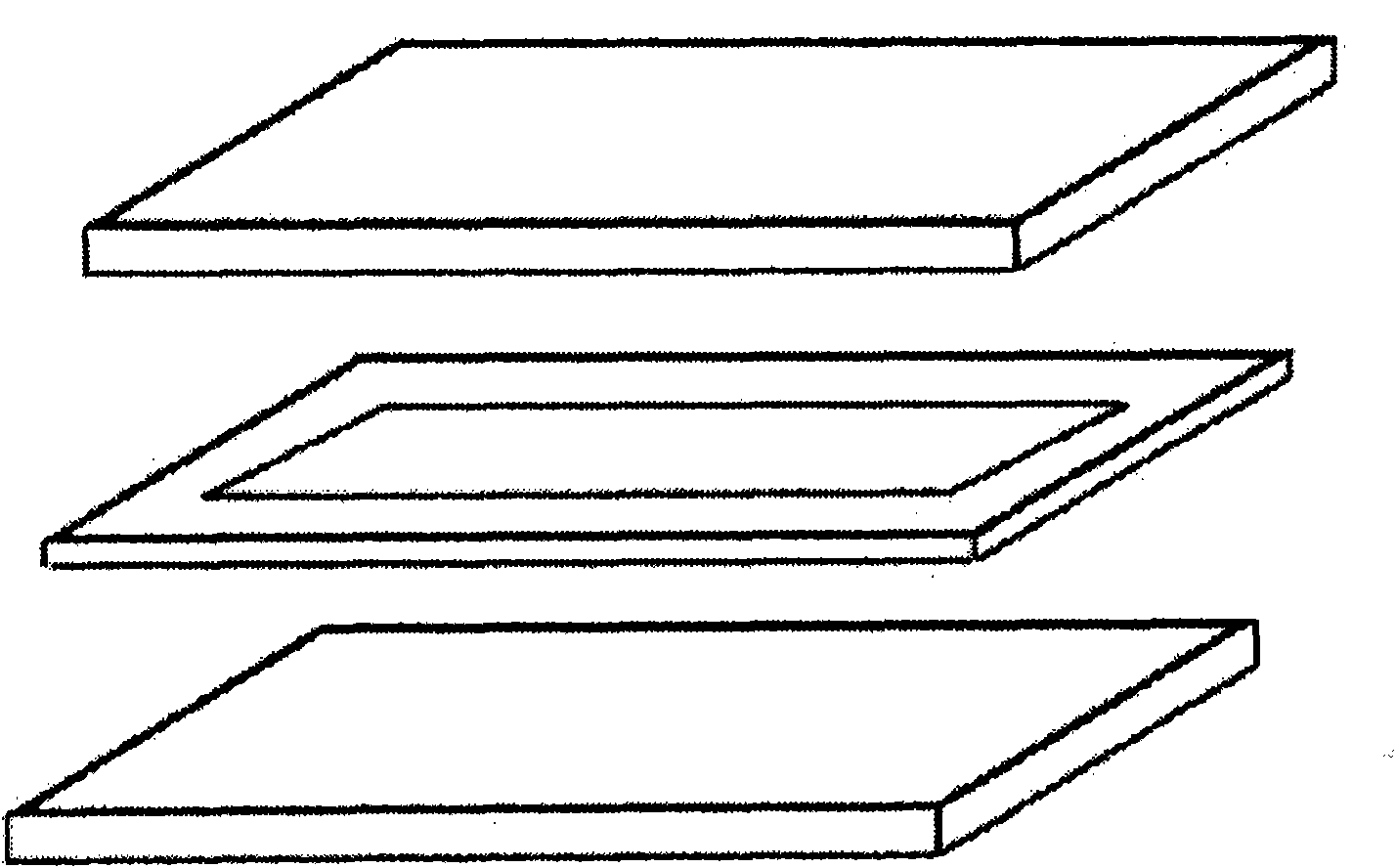

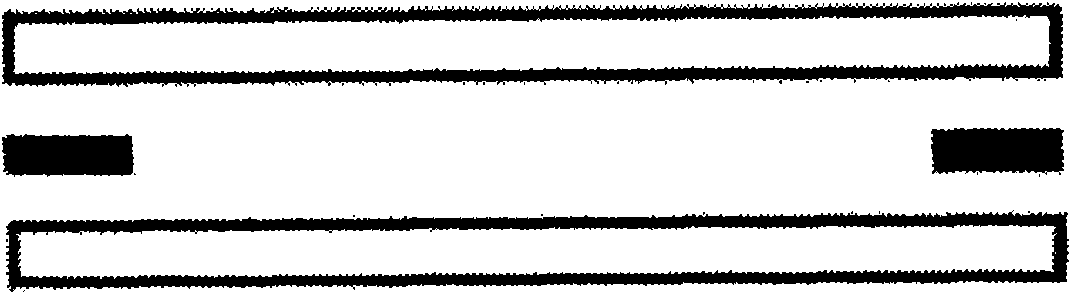

[0048] In the method of manufacturing a photochromic film according to the present invention, the material of the spacer is not particularly limited as long as it does not dissolve in the photochromic composition and has shrinkage according to curing as described above. For example, foamed polyethylene, foamed polyvinyl chloride, foamed PDMS (polydimethylsiloxane), foamed polystyrene, foamed polyurethane, and the like can be used. The spacers may be hollow in shape, or may be filled. Furthermore, its section may be circular, rectangular or trapezoidal, and it may be conical. Depending on the desired thickness of the membrane, one skilled in the art can determine the thickness of the spacer, and according to the desired size of the membrane, the size of the spacer can be determined.

[0049] In the present invention, the material of the substrate may be used without any limitation as long as it is known in the art. For example, glass, metal, plastic substrates can be used, bu...

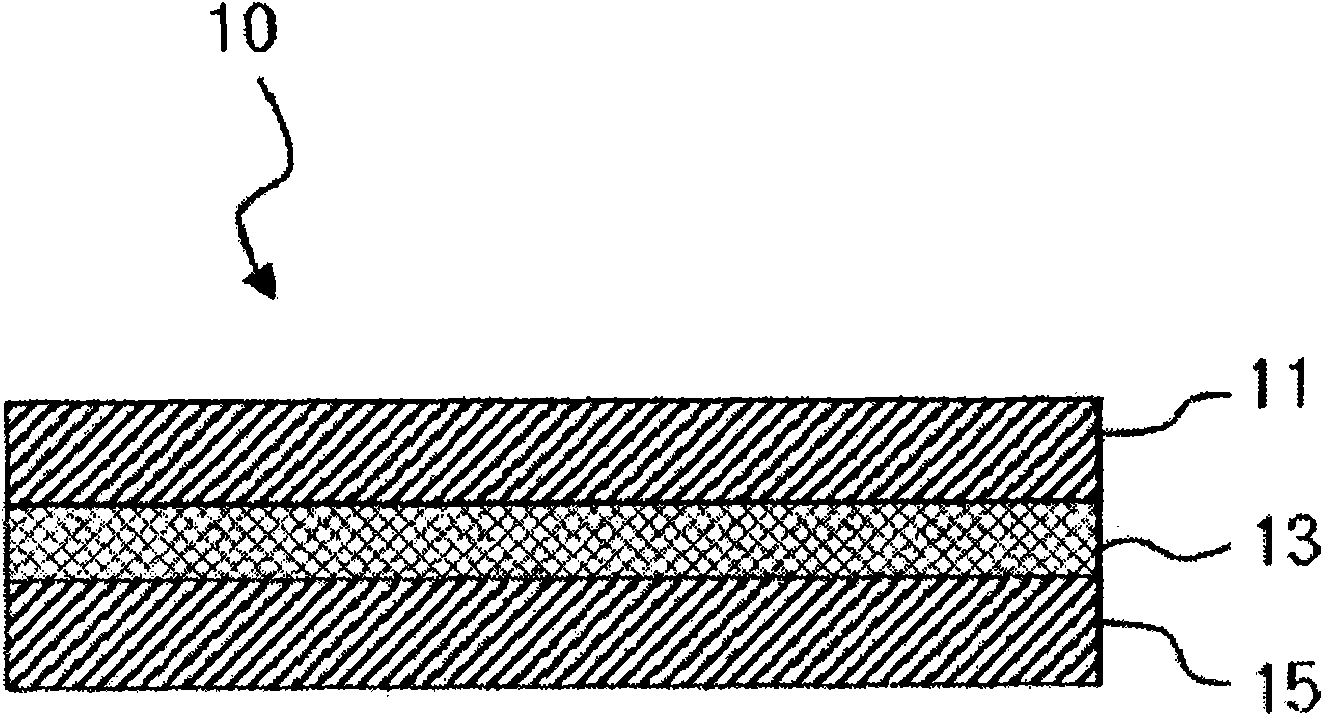

Embodiment 1

[0058] A spacer formed of foamed PVC (polyvinyl chloride), which has a shrinkage of 20% when cured under vacuum compression, shows a thickness between 500- Variation between 400µm. Then, fill the photochromic composition (shrinkage rate: 17%) formed by the composition of the following table 1 between the glass plates, start curing at 25 ° C under normal pressure conditions, and gradually increase the temperature within 4 hours to 100°C, hold at 100°C for 2 hours, then lower the temperature to 25°C over 4 hours. After the curing step, the thickness deviation of the film separated from the glass substrate and spacer was within 5%, and the thickness was 395-410 μm. In addition, when the film is discolored, the optical density is lower than 20% and the oxygen transmission rate is 100 cc / m 2 day atm. The samples were exposed to an ATLASUV 2000 (an accelerated weather resistance tester) using a light intensity of 0.77W / m at 340nm 2 Under the condition of UVA fluorescent lamp at ...

Embodiment 2

[0062] A film was prepared in the same manner as in Example 1 except that foamed PE (polyethylene) having a shrinkage rate of 25% (showing a thickness varying between 400 to 300 μm) was used as a spacer when curing was performed under vacuum compression. After the curing step, the thickness deviation of the film separated from the glass substrate and spacer was within 8%, and the thickness was 305-330 μm. In addition, when the film is discolored, the optical density is lower than 20% and the oxygen transmission rate is 100 cc / m 2 day atm. The sample was exposed to ATLAS UV 2000 (an accelerated weather resistance tester) using a light intensity of 0.77W / m at 340nm 2 Under the condition of UVA lamp at 60°C for 8 hours, and repeated 4 hours of condensation at 50°C as a cycle to measure the optical density and measure the λ min The time required for the transmittance at that point to increase to half of the transmittance at the earlier discoloration step. As a result, the time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| linear shrinkage | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| linear shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com