Production apparatus of multilayer coating film

a production apparatus and coating film technology, applied in lighting and heating apparatus, drying machines with progressive movements, instruments, etc., can solve the problems of large variation in quality, low production efficiency, and inability to efficiently produce high-quality coating films with ordinary coating devices, so as to prevent the wind speed of clean air entering the transfer path case from decreasing, the effect of improving the cleanliness inside the casing and small siz

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

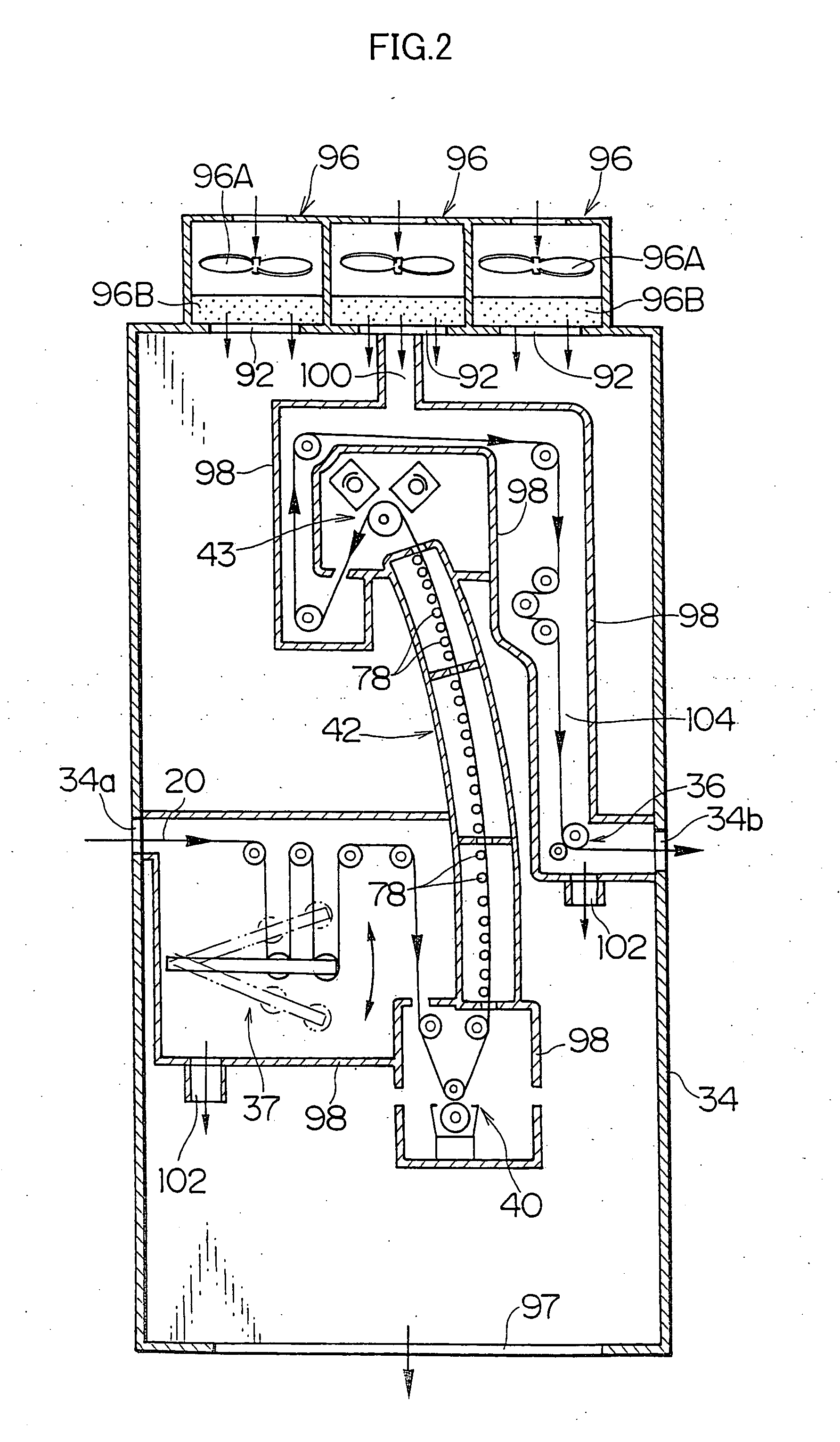

[0029] A preferred embodiment of a production apparatus of a multilayer coating film according to the present invention will be explained in detail below with reference to the attached drawings.

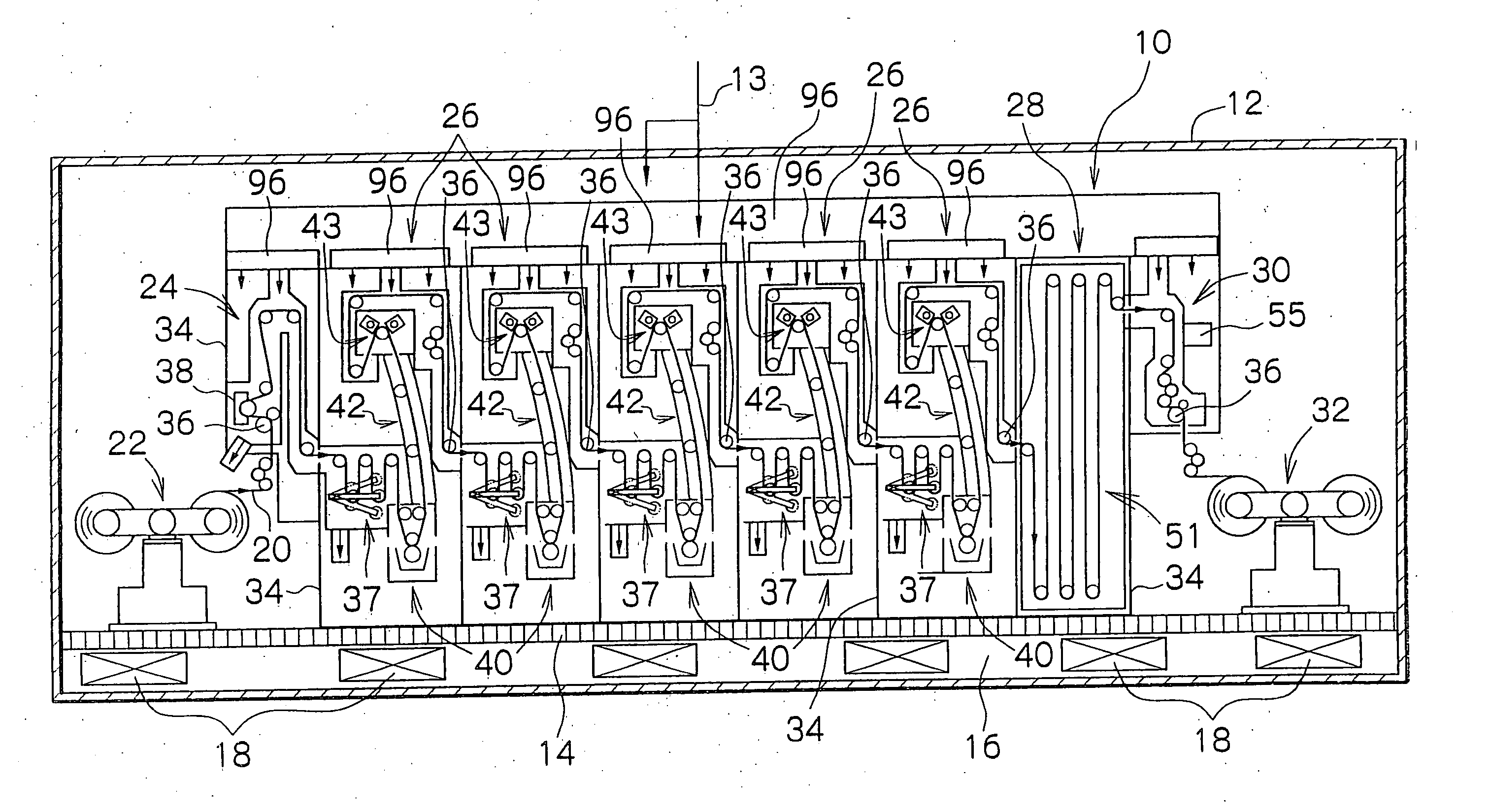

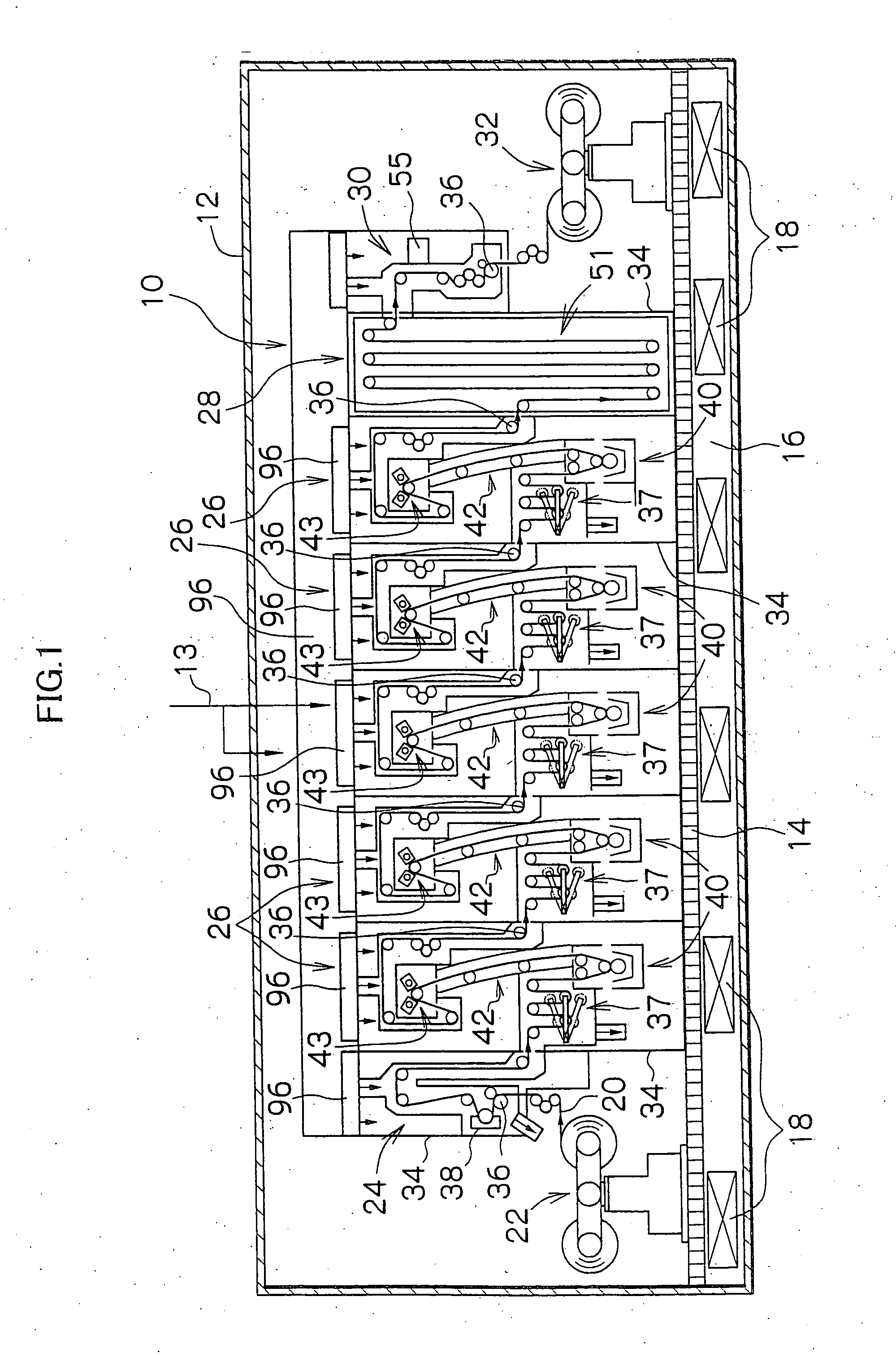

[0030]FIG. 1 is a block diagram of an entire production apparatus of a multilayer coating film according to the present invention and is an example of the production apparatus which produces function films such as a wide view angle film and an antireflection film. The apparatus in FIG. 1 is constructed to produce a multilayer coating film of five layers.

[0031] As shown in FIG. 1, the production apparatus 10 is entirely housed in a production chamber 12, and clean conditioned air is supplied into the production chamber 12 from an air conditioner (not shown) through an air duct 13. A floor surface 14 of the production chamber 12 is formed by a grating floor, and an underfloor space 16 is formed under the floor surface 14. Consequently, the conditioned air supplied into the production chamber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com