Preparation method of electro-optical crystal film, electro-optical crystal film and electro-optical modulator

An electro-optical crystal and thin-film technology, applied in light guide, optics, instruments, etc., can solve problems such as affecting the performance of electro-optical modulators, affecting the propagation of optical signals, and the inability of silicon materials and lithium niobate crystals to be fully bonded.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

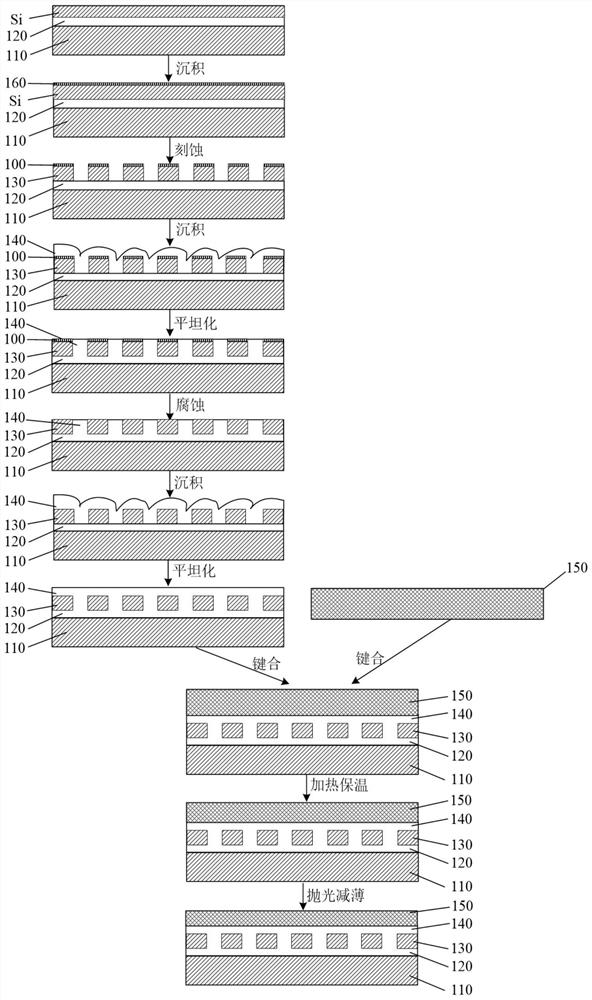

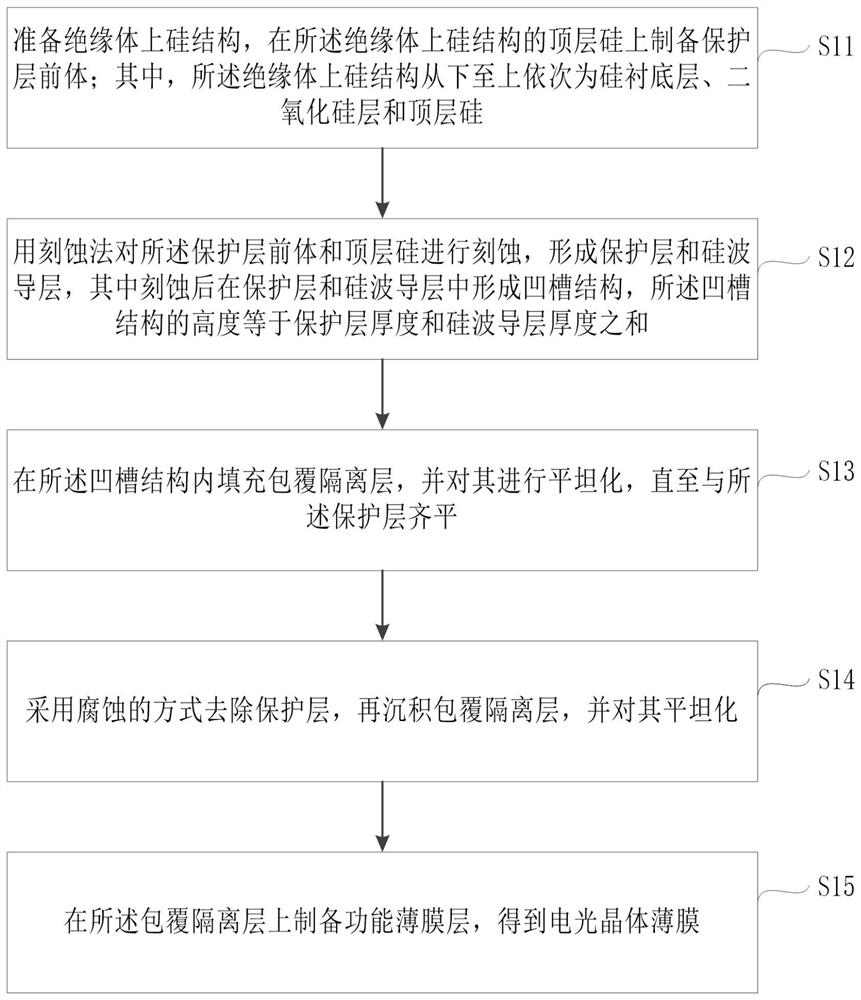

[0032] Specifically, such as figure 2 Shown, described preparation method comprises the following steps:

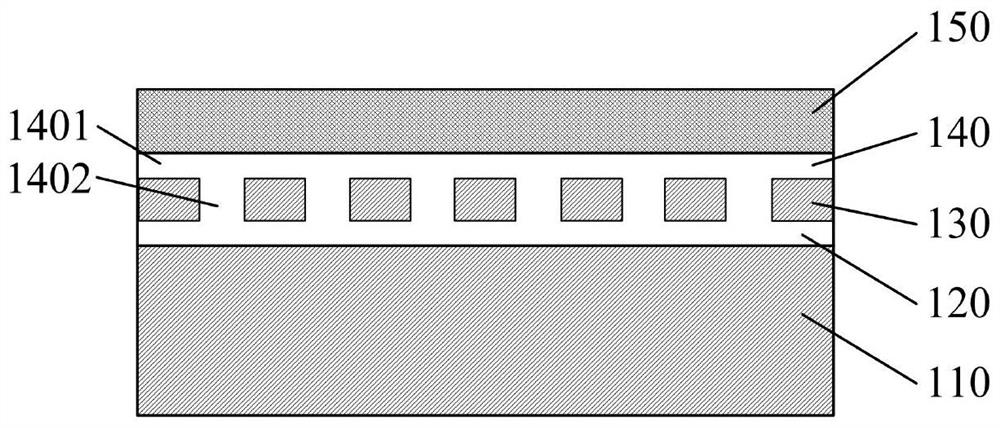

[0033] S11, preparing the SOI structure, depositing a protective layer precursor 160 on the top silicon layer of the SOI structure; wherein, the SOI structure is sequentially composed of a silicon substrate layer 110, a silicon dioxide layer 120 and a top layer of silicon Si from bottom to top.

[0034] In this step, the silicon-on-insulator structure is also called SOI wafer, and the SOI wafer structure from top to bottom is: 50nm-50μm Si / , 50nm-5μm SiO 2 / Si, use LPCVD to deposit a protective layer precursor 160 on the top layer of silicon Si, the thickness of which can be 20nm-2000nm. Of course, PECVD or thermal oxidation method can also be used for depositing the protective layer precursor 160, which is not specifically limited in this step.

[0035]S12, using an etching method to etch the protective layer precursor 160 and the top layer of silicon Si to form the pr...

Embodiment 1

[0076] Embodiment 1 (ion implantation+bonding separation method)

[0077] 1) Prepare an SOI wafer with a size of 4 inches, a thickness of 0.5mm and a smooth surface. The structure of the SOI wafer is 220nm Si / 2μm SiO from top to bottom 2 / Si, cleaning the top layer silicon (Si) of the SOI wafer, and then using LPCVD to deposit a layer of silicon nitride (SiNx) as a protective layer precursor, wherein the thickness of SiNx is 50nm.

[0078] 2) Etching the protective layer precursor and the top layer of silicon on the side of the wafer containing the protective layer precursor described in step 1) using a dry etching method to form a protective layer and a silicon waveguide layer. The silicon on the top layer is completely etched through and etched into a ridge-shaped silicon waveguide. Finally, a groove structure is formed in the protection layer and the silicon waveguide layer, and the height of the groove structure is equal to the sum of the thickness of the protection layer...

Embodiment 2

[0087] Embodiment 2 (method of direct bonding+grinding and polishing)

[0088] 1) Prepare an SOI wafer with a size of 4 inches, a thickness of 0.5mm and a smooth surface. The structure of the SOI wafer is 220nm Si / 2μm SiO from top to bottom 2 / Si, cleaning the top Si layer of the SOI wafer, and then using LPCVD to deposit a layer of silicon carbide as a protective layer precursor, wherein the thickness of silicon carbide is 50nm.

[0089] 2) Etching the protective layer precursor and the top layer of silicon on the side of the wafer containing the protective layer precursor described in step 1) using a dry etching method to form a protective layer and a silicon waveguide layer. The top layer of silicon is not completely etched through, and etched into a ridge-shaped silicon waveguide. Finally, a groove structure is formed in the protection layer and the silicon waveguide layer, and the height of the groove structure is equal to the sum of the thickness of the protection layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com