High-gloss and low-volatility flame retardant polycarbonate composition as well as preparation method and application thereof

A flame-retardant polycarbonate and low-volatility technology, which is applied in the field of high-gloss and low-volatility flame-retardant polycarbonate composition and its preparation, can solve the problems of easy precipitation of molded high-gloss parts, insufficient mechanical properties of materials, and limited compatibility. problems, to achieve excellent mechanical properties, good fluidity, and less volatiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~20

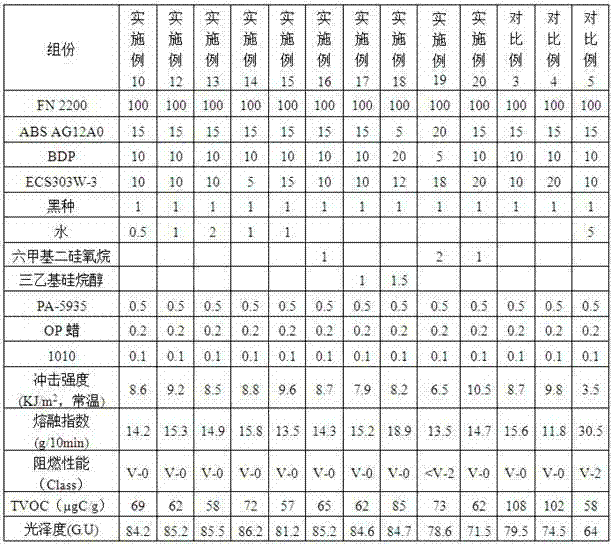

[0053] Embodiment 1~20 and comparative example 1~5

[0054] According to the proportions in Table 1~2, mix the dried PC resin, ABS resin, gloss additives, anti-dripping agent, black seed and additives in a high-speed mixer for 1-2 minutes to obtain a premix, premix The material is put into a twin-screw extruder (screw diameter is 35mm, aspect ratio L / D=36) for melt extrusion, phosphate ester flame retardant and glass fiber are side-fed, and the finished product is obtained by two-stage vacuum granulation. Among them, the temperature of each screw barrel of the twin-screw extruder (from the feeding port to the machine head) is: 140°C, 240°C, 250°C, 250°C, 240°C, 240°C, the screw speed is 300 rpm, and the feeding amount 50kg / h. The product obtained above is dried in an oven at 100° C. for 3-4 hours and then injected into a standard sample strip at a temperature of 250° C. The injection-molded standard strips were placed at 25°C and 50% relative humidity for 24 hours before te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com