Polyurethane grouting material and preparation method thereof

A grouting material and polyurethane technology, applied in the field of polyurethane grouting material and its preparation, can solve the problems of poor injectability, toxicity of organic chemical grouting materials, environmental protection restrictions, etc., and achieve low volatile components, fast and effective sealing. The effect of blocking water and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

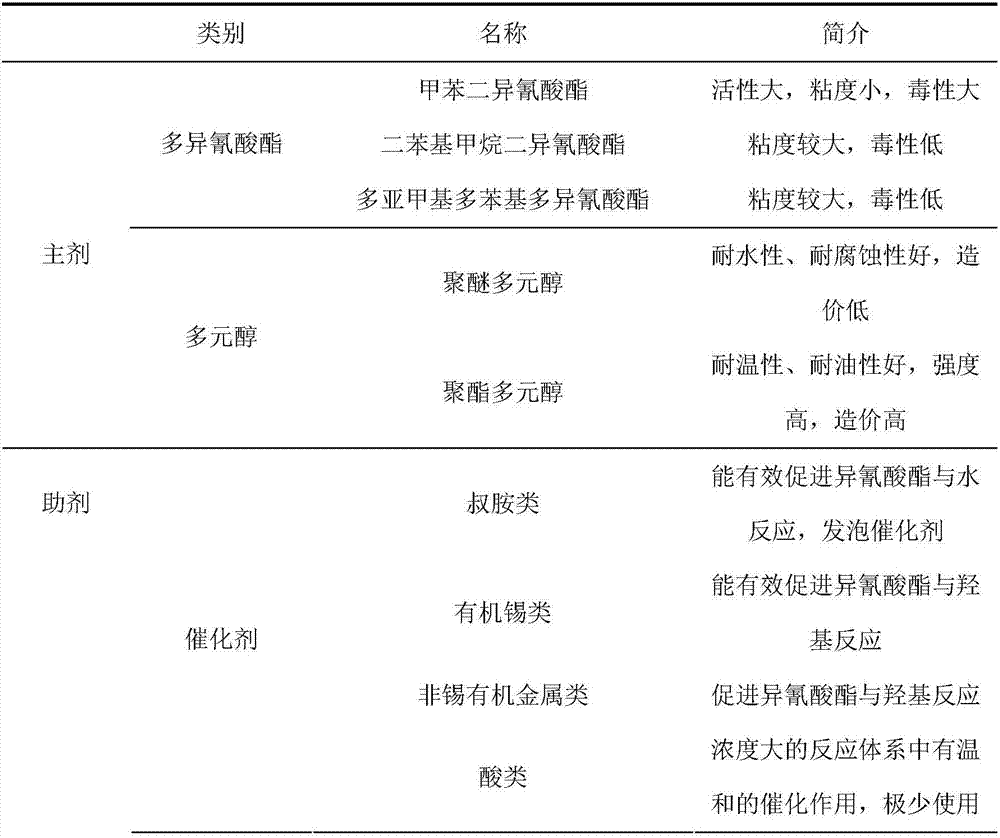

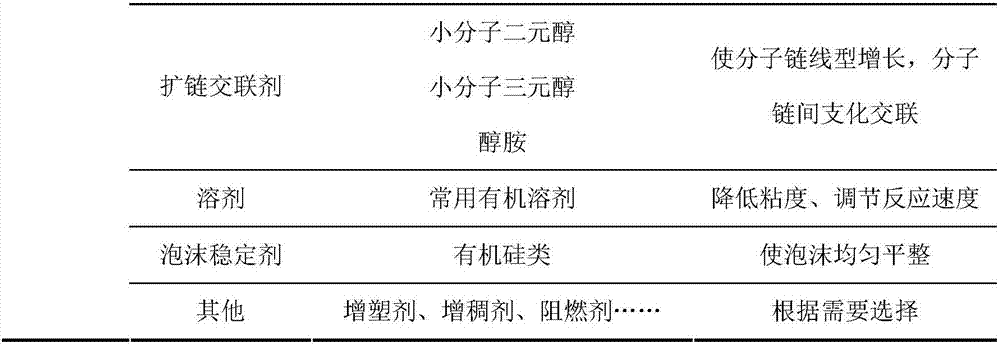

Method used

Image

Examples

preparation example Construction

[0043] A preparation method of polyurethane grouting material, comprising the following steps:

[0044] 1) Accurately weigh a certain mass of polyol, the amount of additive added is calculated according to the percentage of the mass of polyol, after the addition, fully stir with a glass rod to form component B together;

[0045] 2) Weigh polyisocyanate equal to the volume of component B as component A;

[0046] 3) Add an appropriate amount of water to component B to simulate an underground water-rich environment (above 1g);

[0047] 4) Mix components A and B and stir quickly and fully. The system starts to foam and expand, the liquid level rises slowly, and the system gradually becomes viscous. When it reaches a certain height, it stops foaming and rising, and the product gradually hardens. Strength and stiffness, and no stick when the reaction is over.

Embodiment

[0049] The polyisocyanate selected in this embodiment is the polymerized MDI produced by Jining Huakai Resin Co., Ltd., which is a brown liquid at room temperature, with a density of 1.23g / cm3 and a viscosity of 170 ± 5mPa s; polyols are produced by Haian Petrochemical Plant in Jiangsu Province Polyoxypropylene diol, colorless oily liquid at room temperature, density 1.19g / cm3, viscosity 150±5mPa·s; in order to coordinate the reaction of polyisocyanate with polyol and water, tertiary amine catalyst and organotin catalyst are selected at the same time, tertiary The amine catalyst is triethanolamine produced by Sinopharm Chemical Reagent Co., Ltd.; the organic tin catalyst is dibutyltin dilaurate produced by Tianjin Guangxia Fine Chemical Research Institute; the chain-extending cross-linking agent is produced by Sinopharm Chemical Reagent Co., Ltd. The ethylene glycol; Foam stabilizer selects dimethyl silicone oil produced by Guangzhou Suixin Chemical Co., Ltd.

[0050] Raw mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com