High-silicon daily reinforced porcelain and preparation method thereof

A technology for strengthening porcelain and daily use, which is applied in applications, clay products, household appliances, etc. It can solve the problems of unstable components of Longyan raw ore, and achieve the effects of good thermal shock stability, good sintering performance, and high whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

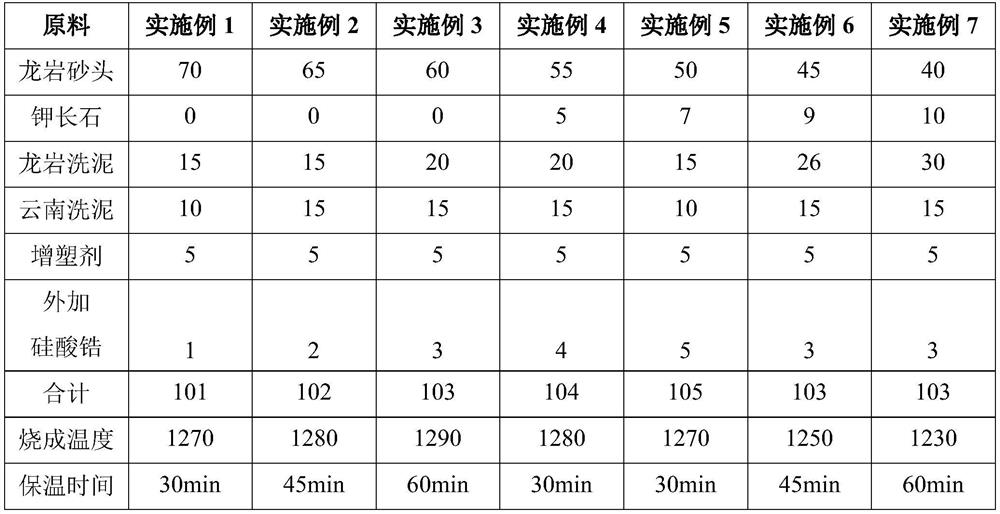

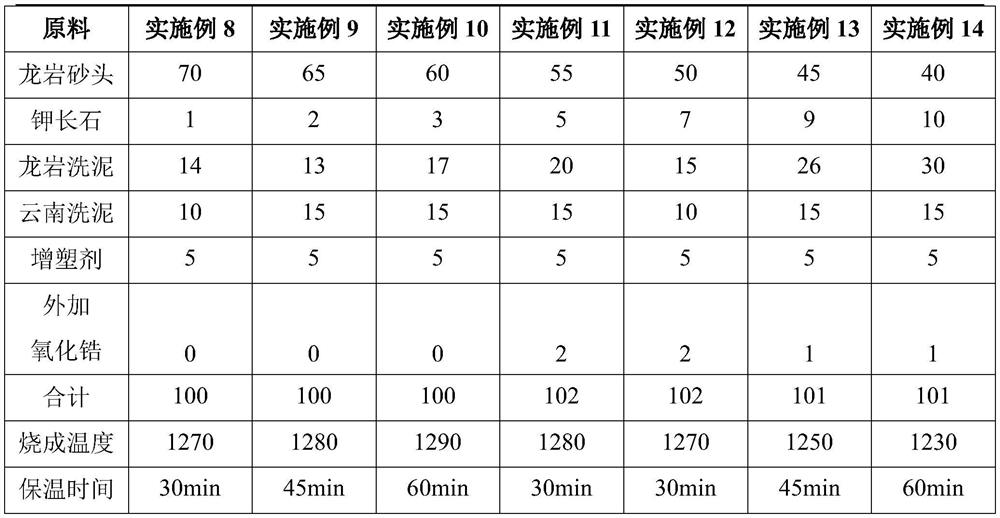

[0022] The high-silica daily-use reinforced porcelain of the present invention has a porcelain body mainly composed of Longyan sandstone, feldspar minerals, and clay minerals. The specific implementation methods are shown in the following table (by mass fraction of each raw material).

[0023]

[0024]

[0025]

[0026]

[0027] The chemical composition (mass fraction) of raw material used is as follows:

[0028] raw material SiO 2

al 2 o 3

CaO MgO K 2 o

Na 2 o

Longyan sand head 84.52 8.67 0.32 0.01 4.83 0.78 Potassium feldspar 67.81 17.95 0.31 0.13 11.52 2.28 Albite 73.45 16.54 0.35 0.15 0.5 8.85 Longyan mud washing 52.44 32.97 0.31 0.26 3.23 0.54 Yunnan mud washing 48.15 35.86 0.17 0.21 1.42 0.34 plasticizer 52.84 22.36 6.97 0.85 0.54 1.85

[0029] Zirconium silicate and zirconia are industrially pure.

[0030] The preparation method of the above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com