Working medium for heat cycle, composition for heat cycle system, and heat cycle system

A technology of working medium and circulation system, which is applied to irreversible circulating compressors, refrigeration components, materials for heat exchange, etc. It can solve the problems of large temperature gradient, difficult recovery of working medium, and poor management of working medium, and achieve temperature gradient. Small, excellent cycle performance, small composition change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0189] Hereinafter, examples of the present invention will be described, but the present invention is not limited to these examples.

[0190] (Evaluation of self-degradability of HFO-1132(E))

[0191] The evaluation of self-decomposability was carried out using a device based on Method A recommended as a device for measuring the combustion range of a gas mixed with a halogen-containing gas in a separate document of the High Pressure Gas Safety Act.

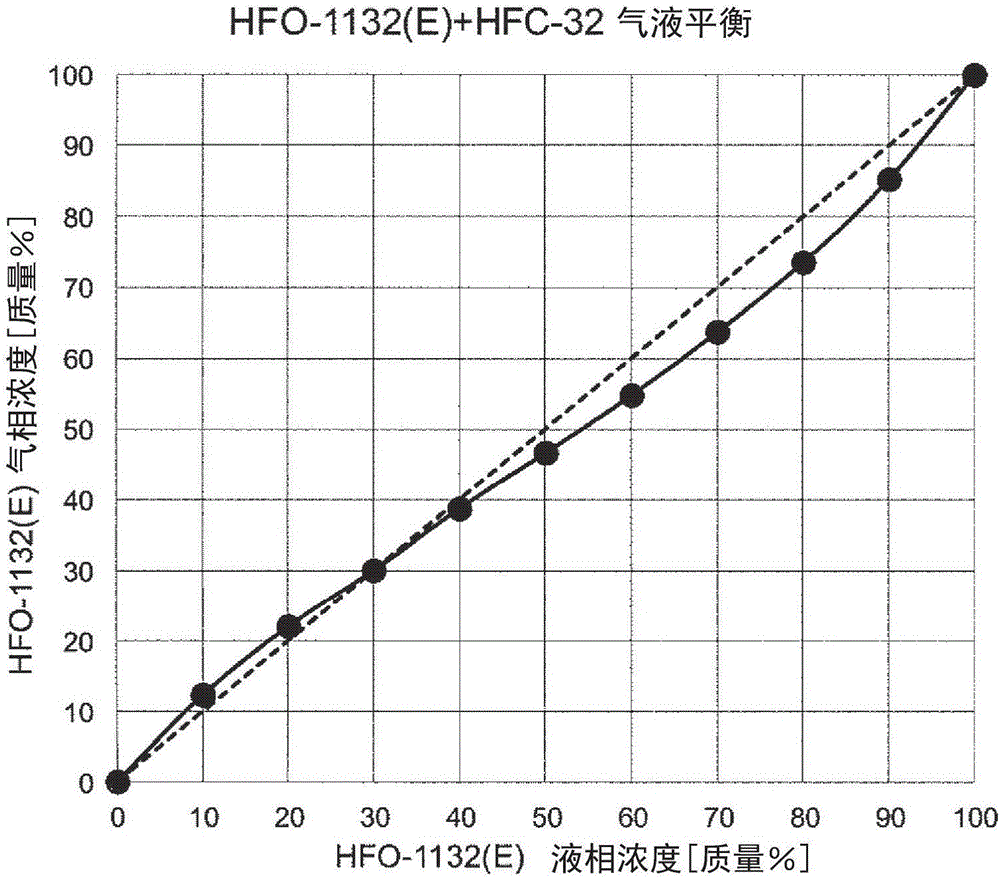

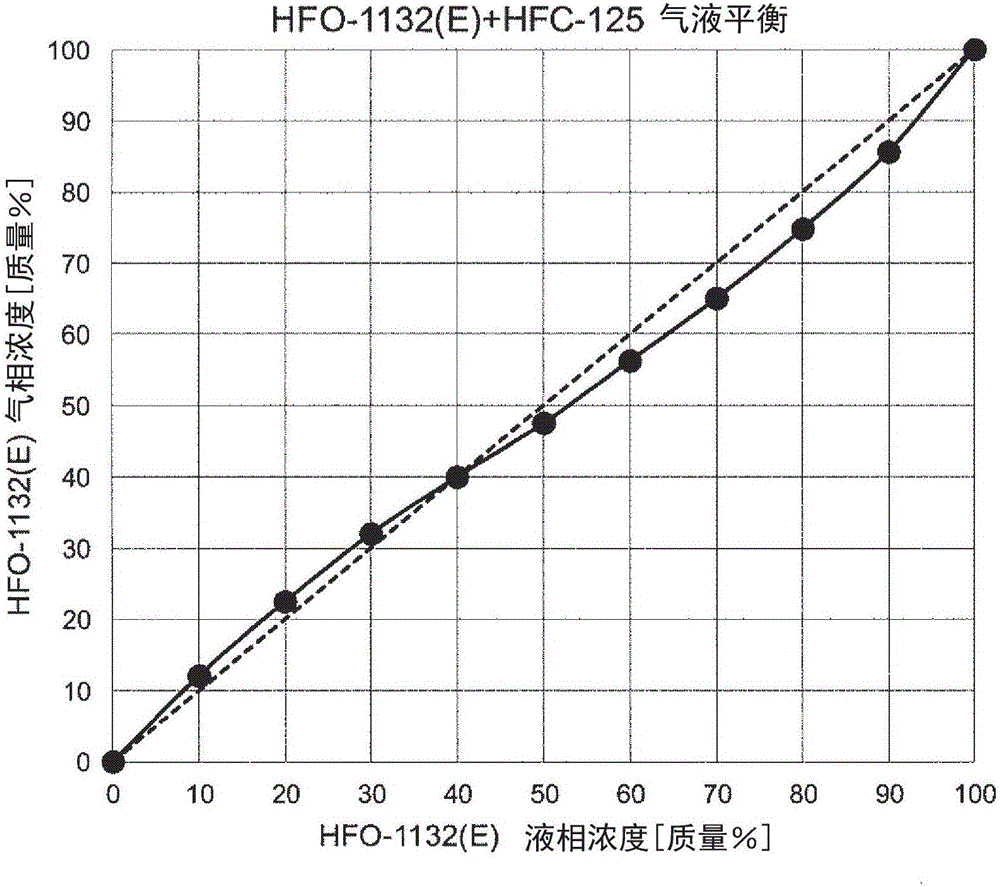

[0192] To be specific, the internal volume is 650cm when the temperature is controlled externally. 3 After sealing the thermal cycle working medium obtained by mixing HFO-1132(E) and HFC-32 or HFC-125 in various proportions in a spherical pressure-resistant container at a specified pressure, the platinum wire installed inside is fused An energy of about 30J was applied. The presence or absence of self-decomposition was confirmed by measuring the temperature and pressure changes in the pressure-resistant container after energy ap...

example 1

[0197] (Evaluation of refrigeration cycle performance)

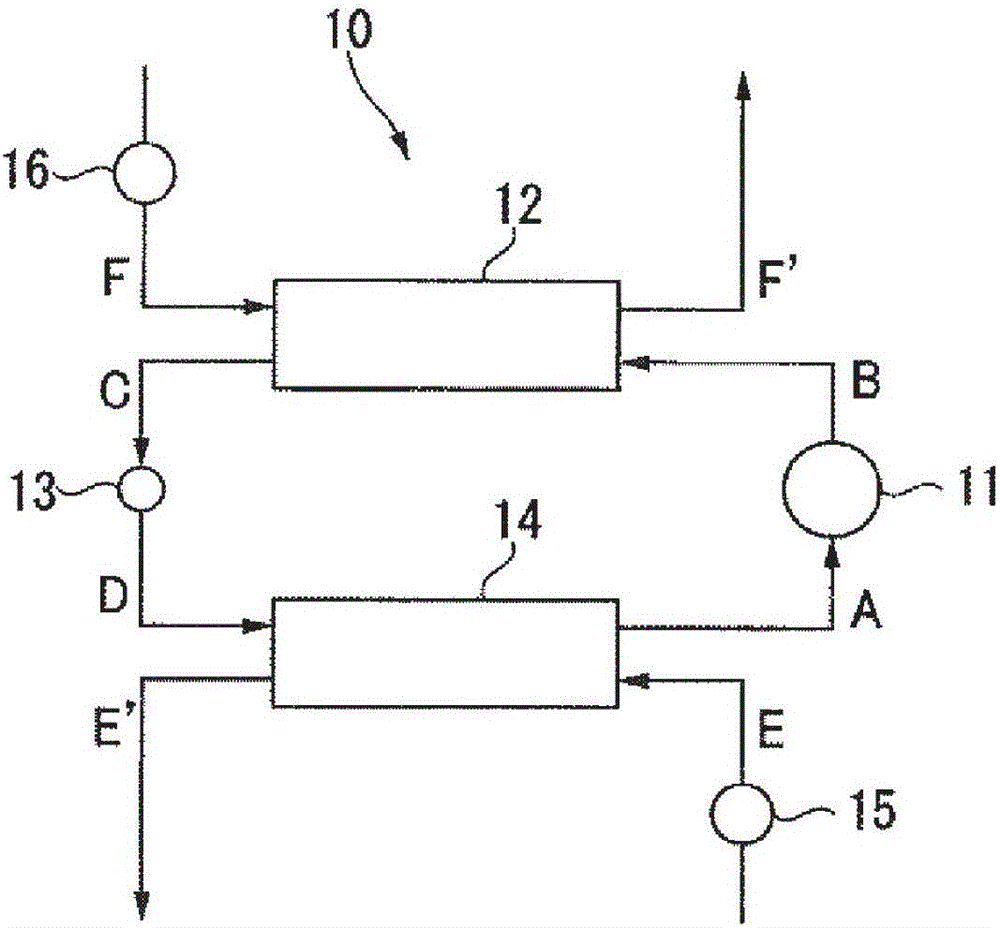

[0198] The cycle performance evaluation of the thermal cycle working media 1-28 composed of this type of azeotropic composition shown in Tables 4-6 was carried out as follows. exist image 3 In the refrigerating cycle system 10 of the above-mentioned thermal cycle using the working medium 1~28 respectively, in image 3 The thermal cycle shown, i.e. adiabatic compression using compressor 11 in process AB, isobaric cooling using condenser 12 in process BC, isenthalpic expansion using expansion valve 13 in process CD, and evaporation in process DA The refrigeration cycle performance (refrigeration capacity and efficiency coefficient) was evaluated as the cycle performance (capacity and efficiency) when the device 14 performed isobaric heating.

[0199] The evaluation was carried out under the following conditions: the average evaporation temperature of the working medium for thermal cycle in the evaporator 14 is 0°C, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com