Extremely-thick low alloy steel plate for E-level high purity ocean platform and production method thereof

A technology of offshore platform and production method, which is applied in the field of metallurgy, can solve the problems of thickness level not meeting the user's requirements, unevenness, and small margin, etc., and achieve good comprehensive mechanical properties and welding performance, high purity, and main The effect of little change in composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

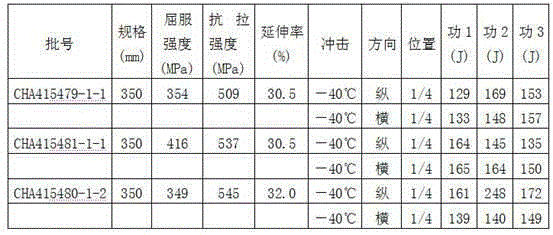

Examples

Embodiment 1

[0036] The steel grade EH36 of present embodiment, steel plate thickness is 350mm, and the step of production method is as follows:

[0037] (1) Smelting: It will contain the following weight percentages C: 0.16%, Si: 0.30%, Mn: 1.39%, P: 0.014%, S: 0.001%, Al: 0.018%, Nb: 0.026%, V: 0.052%, Ti: The molten steel with 0.001% composition is smelted in electric furnace first, and then sent to LF refining furnace for refining. When the temperature of molten steel reaches 1620℃, it is transferred to VD furnace for vacuum degassing treatment. Before VD, 100kg / furnace of CaSi block is added to change the shape of inclusions; The vacuum degree of the VD furnace is 57Pa, and the vacuum holding time is 20 minutes to ensure the effective removal of inclusions and gases and the purity of molten steel;

[0038] (2) Continuous casting: low-carbon mold slag is used, the billets are off-line and stacked for 24 hours, cleaned with temperature, transferred to an electroslag remelting furnace to...

Embodiment 2

[0050] The steel grade EH36 of present embodiment, steel plate thickness is 330mm, and the step of production method is as follows:

[0051] (1) Smelting: will contain the following weight percentages C: 0.18%, Si: 0.35%, Mn: 1.60%, P: 0.014%, S: 0.001%, Al: 0.010%, Nb: 0.020%, V: 0.065%, Ti: The molten steel with 0.001% composition is smelted in electric furnace first, and then sent to LF refining furnace for refining. When the temperature of molten steel reaches 1640℃, it is transferred to VD furnace for vacuum degassing treatment. Before VD, add CaSi block 120kg / furnace to change the shape of inclusions; The vacuum degree of the VD furnace is 61Pa, and the vacuum holding time is 30 minutes to ensure the effective removal of inclusions and gases and the purity of molten steel;

[0052] (2) Continuous casting: low-carbon mold slag is used, the billets are off-line and stacked for 26 hours, cleaned with temperature, transferred to an electroslag remelting furnace to make bille...

Embodiment 3

[0062] The steel grade EH36 of present embodiment, steel plate thickness is 300mm, and the step of production method is as follows:

[0063] (1) Smelting: will contain the following weight percentages C: 0.10%, Si: 0.15%, Mn: 0.90%, P: 0.015%, S: 0.002%, Al: 0.020%, Nb: 0.030%, V: 0.035%, Ti: The molten steel with 0.002% composition is smelted in an electric furnace first, and sent to an LF refining furnace for refining. When the temperature of the molten steel reaches 1630°C, it is transferred to a VD furnace for vacuum degassing treatment. Before VD, 110kg / furnace of CaSi block is added to change the shape of inclusions; The vacuum degree of the VD furnace is 66.6Pa, and the vacuum holding time is 22 minutes to ensure the effective removal of inclusions and gases and the purity of molten steel;

[0064] (2) Continuous casting: low-carbon mold slag is used, the billets are off-line and stacked for 25 hours, cleaned with temperature, transferred to an electroslag remelting fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com