Photoresist residue and polymer residue removing liquid composition

A technology of photoresist and composition, applied in the preparation of detergent mixture composition, detergent composition, non-surface active detergent composition, etc., can solve the problems of pollution, high melting point, etc., and achieve the improvement of reverse Effects of pollution, high solubility, high complexing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

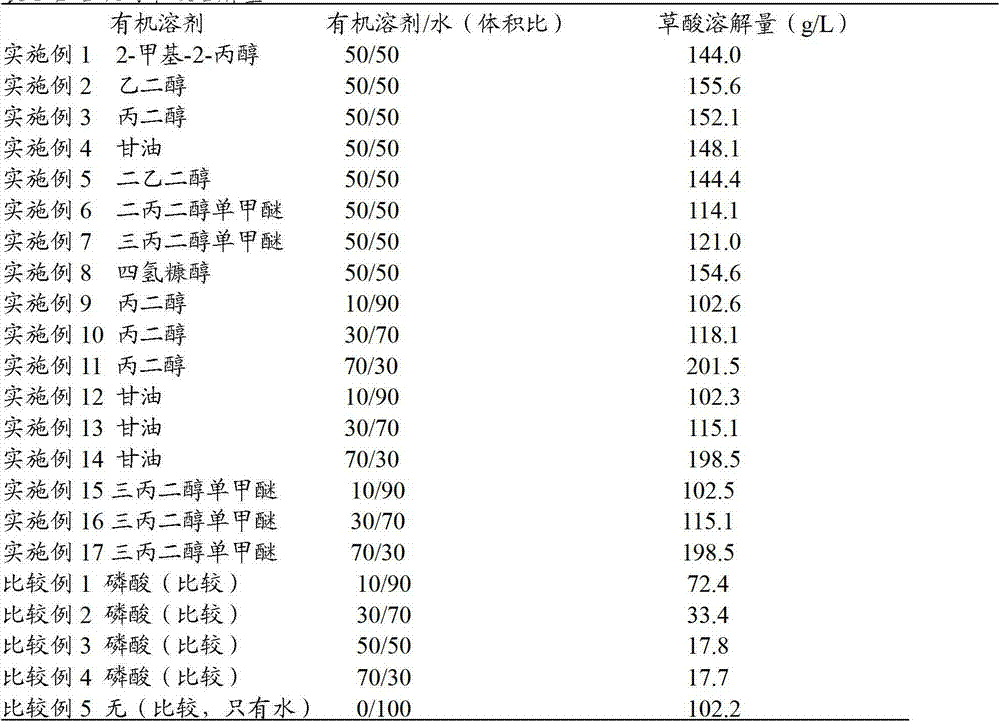

[0065] Next, the present invention will be described in more detail through examples and comparative examples about the photoresist residue and polymer residue removing liquid composition of the present invention, but the present invention is not limited to these examples.

[0066]

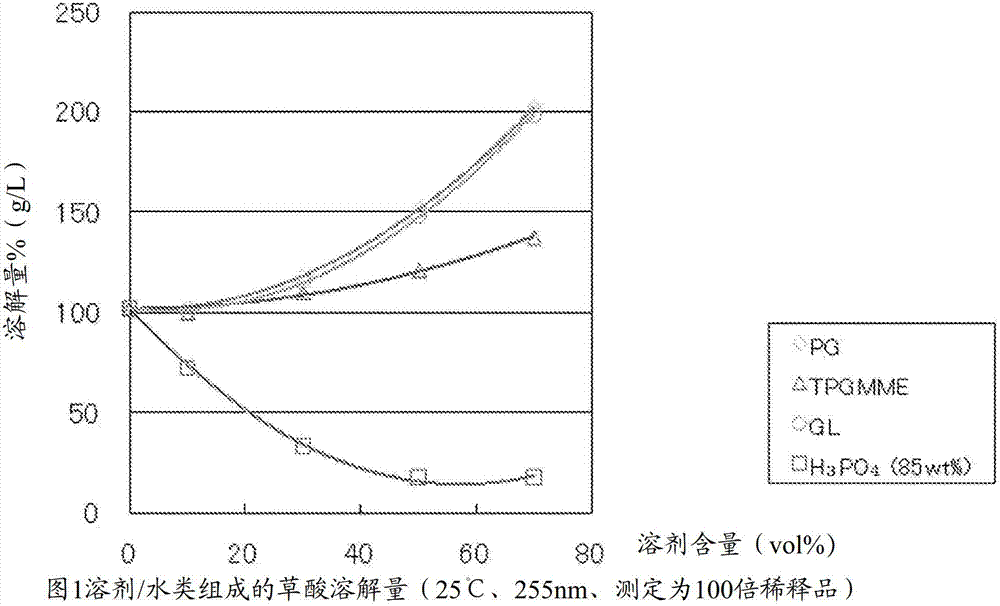

[0067] Oxalic acid (acid anhydride) (20 g) was added to each solution (100 ml), and it was left to stand in a sealed state with stirring for more than 12 hours. Then the supernatant was diluted 100 times, and the absorbance at 255 nm was measured using a spectrophotometer, and the solubility of oxalic acid was calculated.

[0068] Table 1 shows the amount of oxalic acid dissolved in each solution.

[0069] Table 1

[0070] The amount of oxalic acid dissolved in each solution of table 1

[0071]

[0072] figure 1 The amount of oxalic acid dissolved in each solution after changing the volume ratio of the organic solvent to water is shown. PG in the figure represents propylene glycol, TPGMME...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com