F-grade large-thickness weldable steel plate with high pureness and high low-temperature toughness and production method thereof

A production method and high and low temperature technology, applied in the field of F-grade ultra-thick high-strength steel, can solve the problems that the smelting and casting methods cannot meet the needs, the internal quality cannot meet the requirements, etc., and achieve good comprehensive mechanical properties and welding properties. The effect of isotropic and Z-direction performance, good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

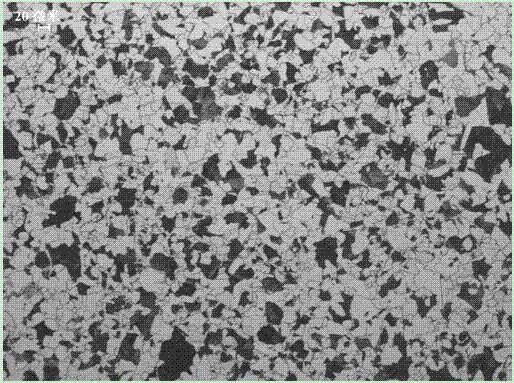

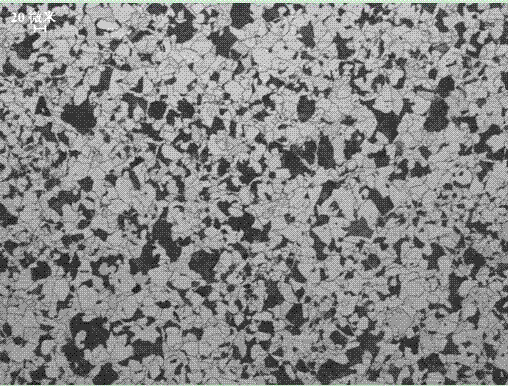

Image

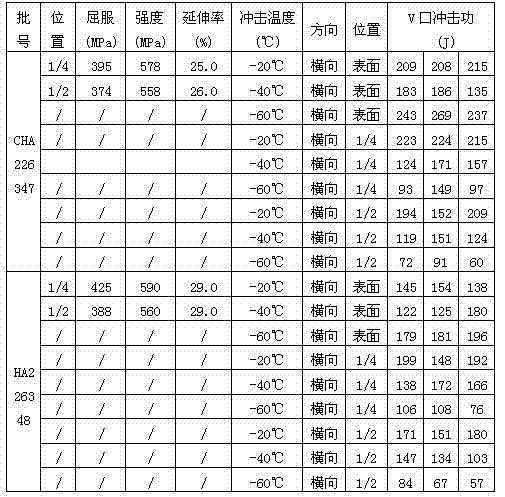

Examples

Embodiment 1

[0033] Example 1: The specific production steps of the high-purity, high-low temperature toughness F-grade large-thickness easy-to-weld steel plate are as follows, and the finished thickness of the steel plate is 350 mm.

[0034] (1) Smelting: It will contain the following weight percentages C: 0.15%, Si: 0.17%, Mn: 1.18%, P: 0.011%, S: 0.001%, Al: 0.016%, Nb: 0.031%, V: 0.045%, Ti: 0.001% molten steel is first smelted in an electric furnace, sent to an LF refining furnace for refining, and then transferred to a VD furnace for vacuum degassing treatment. Before VD, CaSi block ≥ 100kg / furnace or Fe-Ca wire is added to change the shape of inclusions; VD The vacuum degree of the furnace is 65.2Pa, and the vacuum holding time is 18 minutes to ensure the effective removal of inclusions and gases and the purity of molten steel.

[0035] (2) Continuous casting: low-carbon mold slag is used, the billets are off-line and stacked for 26 hours, cleaned with temperature, and transferred t...

Embodiment 2

[0044] Embodiment 2: The specific production steps of the steel plate are as follows, and the finished thickness of the steel plate is 420 mm.

[0045] (1) Smelting: It will contain the following weight percentages C: 0.17%, Si: 0.30%, Mn: 1.38%, P: 0.012%, S: 0.001%, Al: 0.017%, Nb: 0.033%, V: 0.048%, Ti: 0.002% molten steel is smelted in an electric furnace first, sent to an LF refining furnace for refining, and then transferred to a VD furnace for vacuum degassing treatment. Before VD, CaSi block ≥ 100kg / furnace or Fe-Ca wire is added to change the shape of inclusions; VD The vacuum degree of the furnace is 62.5Pa, and the vacuum holding time is 20 minutes to ensure the effective removal of inclusions and gases and the purity of molten steel.

[0046] (2) Continuous casting: low-carbon mold slag is used, the billets are off-line and stacked for 27 hours, cleaned with temperature, and transferred to an electroslag remelting furnace to make billets.

[0047] (3) Electroslag ...

Embodiment 3

[0056] Embodiment 3: The specific production steps of the steel plate are as follows, and the thickness of the finished steel plate is 500 mm.

[0057] (1) Smelting: It will contain the following weight percentages C: 0.18%, Si: 0.24%, Mn: 1.40%, P: 0.011%, S: 0.001%, Al: 0.016%, Nb: 0.028%, V: 0.050%, The molten iron with Ti: 0.001% component is first smelted, then sent to the LF refining furnace for refining, and then transferred to the VD furnace for vacuum degassing treatment; the vacuum degree of the VD furnace is 60.1Pa, and the vacuum holding time is 20min to ensure the inclusions and gases. Effective removal to ensure the purity of molten steel.

[0058] (2) Continuous casting: low-carbon mold slag is used, the billets are off-line and stacked for 30 hours, cleaned with temperature, and transferred to an electroslag remelting furnace to make billets.

[0059] (3) Electroslag remelting: The electroslag furnace adopts a crystallizer with a thickness of 960mm and its mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com