Platinum group alloy manufacturing method

一种制造方法、基合金的技术,应用在铂族基合金的制造领域,能够解决合金组成变动等问题,达到组成变动小、减低经济损失、蒸发抑制效果高的效果

Active Publication Date: 2016-11-16

ISHIFUKU METAL IND CO LTD

View PDF7 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] Regarding vacuum plasma melting and / or electron beam melting, there is usually the ability to continuously cast a large amount of alloys compared to non-consumable electrode type arc melting, and since the melting atmosphere is vacuum, impurities can be evaporated and removed (refining effect), so It is suitable for the melting of pure metals, but when melting alloys, the constituent elements with high vapor pressure evaporate more, which changes the composition of the alloy

[0009] In this way, the melting method widely used in the past has limitations in producing a large amount of platinum-group-based alloys without compositional fluctuations with good yields.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0064] Further illustrate with embodiment. Table 1 shows the experimental conditions of Examples and Comparative Examples, Table 2 shows the experimental results of Examples and Comparative Examples, and Table 3 shows the evaluation of these results.

[0065] Table 1

[0066] The experimental conditions of table 1-embodiment and comparative example

[0067]

[0068] Table 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Login to View More

Abstract

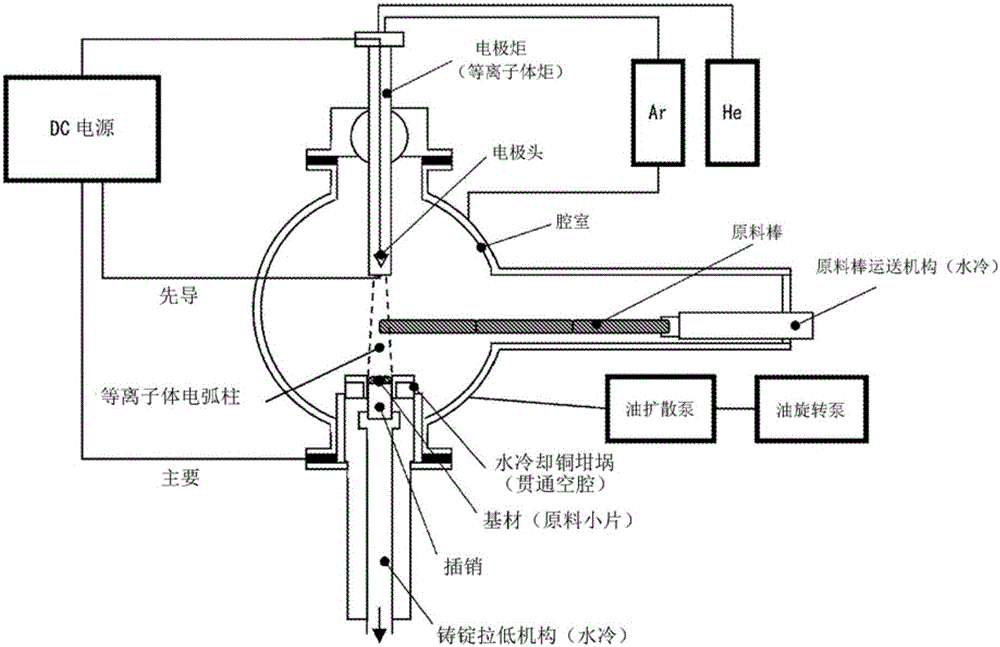

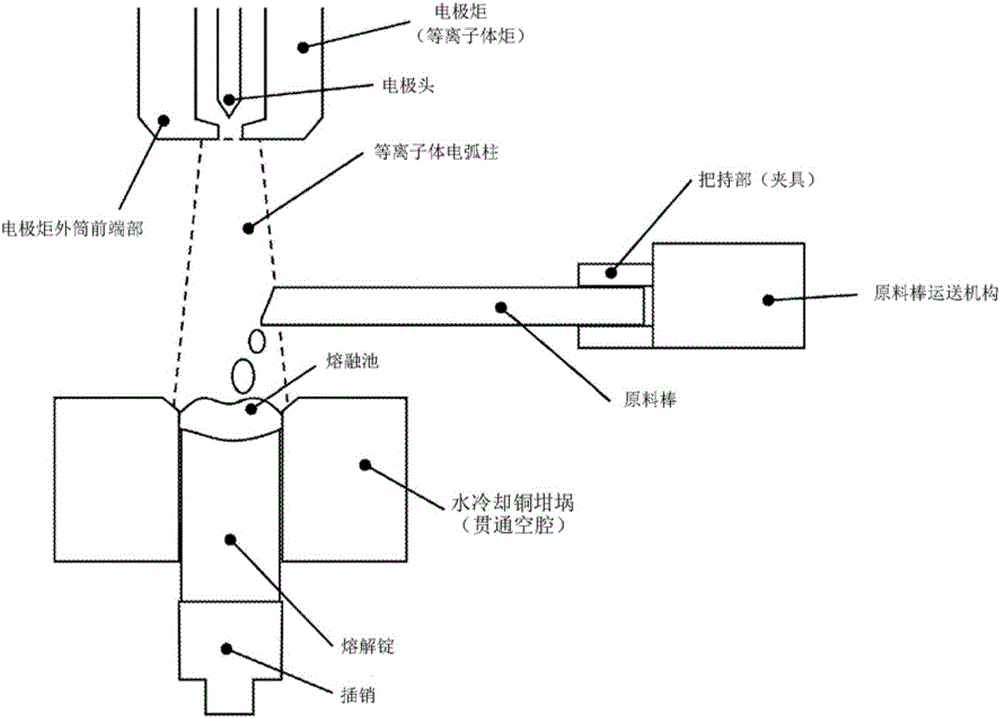

The present invention is a continuous founding-type melt ingot manufacturing process in which used is a plasma arc melting furnace in which a plasma arc column is formed between an electrode torch disposed inside and at an upper part of a vacuum chamber and a water-cooled copper crucible which is provided with a cavity having a cross sectional area S1 and which is disposed inside and at a lower part of the chamber. While the end portion of a raw material rod formed of a platinum group alloy is inserted into the plasma arc column and melted, the melted material is caused to drip onto a base material inside of the water-cooled copper crucible and form a molten pool. While the height of the liquid surface of the molten pool is maintained at a constant height by lowering the base material, the bottom portion of the molten pool is caused to solidify. The horizontal cross-sectional area S (mm2) and the length L (mm) of the melt ingot satisfy S1>=S>500, L>4 radical sign (S / Pi), the internal pressure of the chamber at the time of melting is at least 0.8atm, and the lowering speed is no more than 10mm / min.

Description

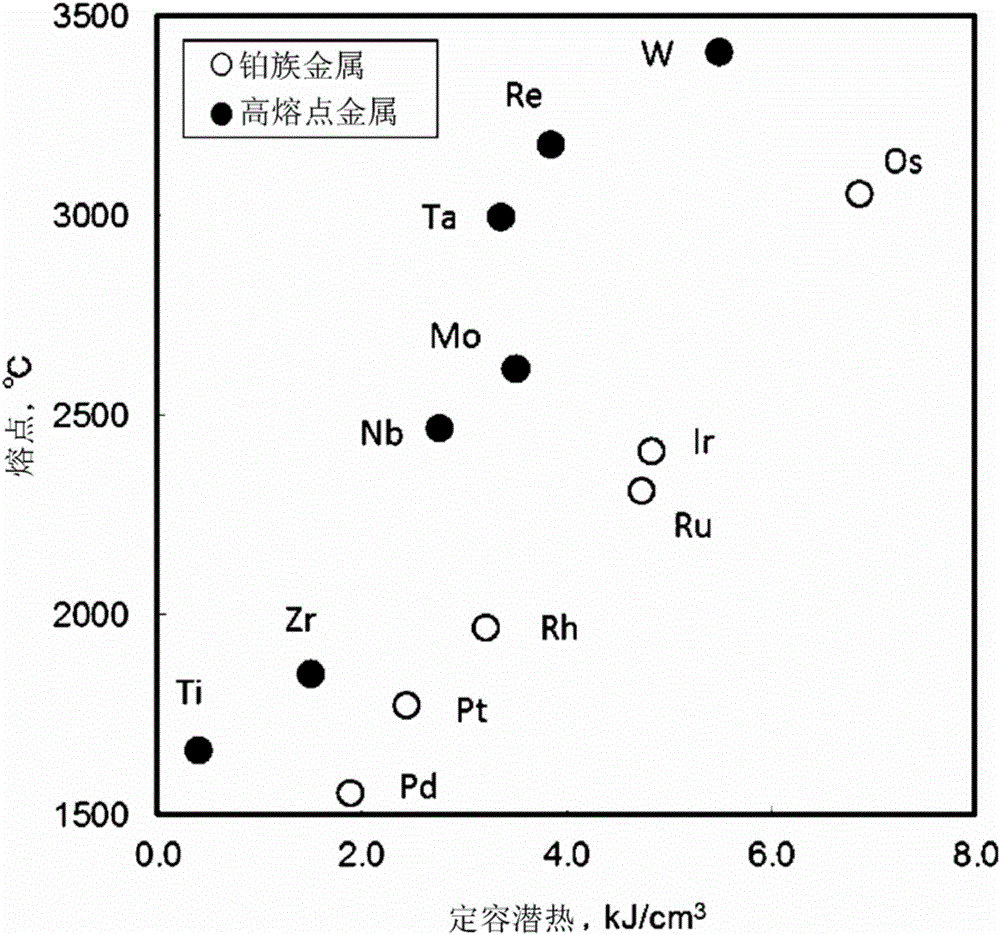

technical field [0001] The invention relates to a method for manufacturing a platinum group-based alloy, in particular to the manufacture of a molten ingot in the method for manufacturing a platinum group-based alloy. Background technique [0002] Platinum group-based alloys are designed by utilizing the heat resistance, oxidation resistance, and chemical resistance of platinum group metals, and are widely used as high-temperature components and / or corrosion-resistant products. Here, the platinum group metal refers to a generic term of Pt, Pd, Rh, Ir, Ru, and Os. [0003] The manufacturing process of platinum group-based alloys generally includes a compounding process of alloy raw materials, a melting process, a plastic processing process, etc., and the melting method is divided into several types. The melting point of platinum group metals, which are the main components, is very high, so an induction heating melting furnace or an energy beam melting furnace is used. [00...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B22D11/041B22D11/00B22D11/18

CPCB22D11/00B22D11/041B22D7/005C22C1/02C22C5/04C22F1/14B22D11/18B22D27/02

Inventor 土井义规今大助

Owner ISHIFUKU METAL IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com