Cu-Ti2 AlC functionally gradient material and preparation method thereof

A functionally graded material, gradient distribution technology, applied in chemical instruments and methods, layered products, metal layered products, etc., to achieve high melting point, prolong service life, and overcome the effects of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Taking the 4-layer gradient change as an example, Cu and Ti 2 The total volume of AlC is calculated as 100%, Cu and Ti in the gradient distribution layer 2 The volume fraction of AlC is shown in Table 1:

[0024] Table 1 Cu and Ti in gradient distribution layer 2 Volume percentage of AlC

[0025] raw material Tier 1 layer 2 layer 3 layer 4 Cu 100% 80% 60% 40% Ti 2 AlC 0 20% 40% 60%

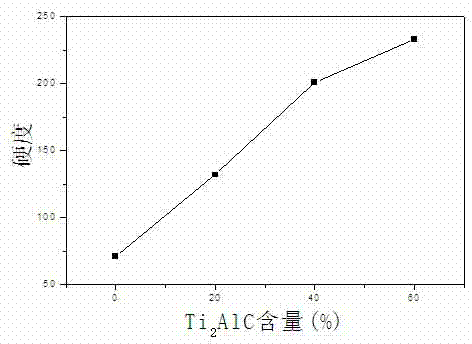

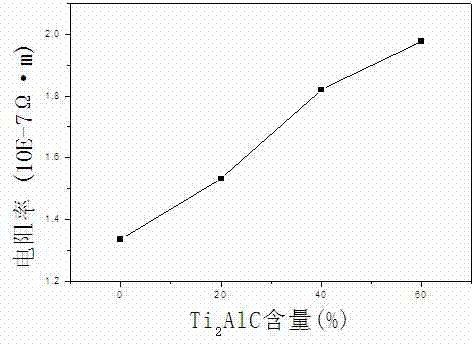

[0026] Weigh Cu and Ti respectively in proportion 2 After the AlC powder is mixed, it is ball milled with alcohol for 4 hours to mix evenly, and it is loaded into a graphite grinding tool layer by layer to form a gradient distribution layer, and it is hot-pressed and sintered in a vacuum environment. The heating rate is 8°C / min, the sintering temperature is 850°C, the pressure is 30MPa, and the temperature is kept for 1.5 hours. The relative density of the obtained sintered body is 97%, and the resistivity is less than 2.0*10 -7 Ω m, change of ...

Embodiment 2

[0028] Taking the 4-layer gradient change as an example, Cu and Ti 2 The total volume of AlC is calculated as 100%, Cu and Ti in the gradient distribution layer 2 The volume fraction of AlC is shown in Table 2:

[0029] Table 2 Cu and Ti in gradient distribution layer 2 Volume percentage of AlC

[0030] raw material Tier 1 layer 2 layer 3 layer 4 Cu 97% 70% 50% 30% Ti 2 AlC 3% 30% 50% 70%

[0031] Weigh Cu and Ti respectively in proportion 2 After the AlC powder is mixed, it is ball-milled with alcohol as the medium for 6 hours to mix evenly, and it is loaded into the graphite grinding tool layer by layer to form a gradient distribution layer, and it is hot-pressed and sintered under the Ar atmosphere. The heating rate is 10°C / min, the sintering temperature is 930°C, the pressure is 35MPa, and the temperature is kept for 2 hours. The relative density of the obtained sintered body is greater than 98%, and the resistivity is less tha...

Embodiment 3

[0033] Taking the 5-layer gradient change as an example, Cu and Ti 2 The total volume of AlC is calculated as 100%, Cu and Ti in the gradient distribution layer 2 The volume fraction of AlC is shown in Table 3:

[0034] Table 3 Cu and Ti in gradient distribution layer 2 Volume percentage of AlC

[0035] raw material Tier 1 layer 2 layer 3 layer 4 layer 5 Cu 95% 80% 60% 40% 20% Ti 2 AlC 5% 20% 40% 60% 80%

[0036] Weigh Cu and Ti respectively in proportion 2 After the AlC powder is mixed, it is ball-milled with alcohol as the medium for 8 hours to mix evenly, and it is loaded into the graphite grinding tool layer by layer to form a gradient distribution layer, and it is hot-pressed and sintered in a vacuum environment. The heating rate is 10°C / min, the sintering temperature is 950°C, the pressure is 40MPa, and the temperature is kept for 2 hours. The relative density of the obtained sintered body reaches more than 98%, and the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com