Method for producing propylene continuously in switch mode

A switchable, propylene technology, which is applied in the direction of hydrocarbon cracking, hydrocarbon production, organic chemistry, etc., can solve the problems of large changes in the composition of reaction products, stable product quality and difficult operation of subsequent processes, and achieve small changes in composition and stable product quality , the effect of good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

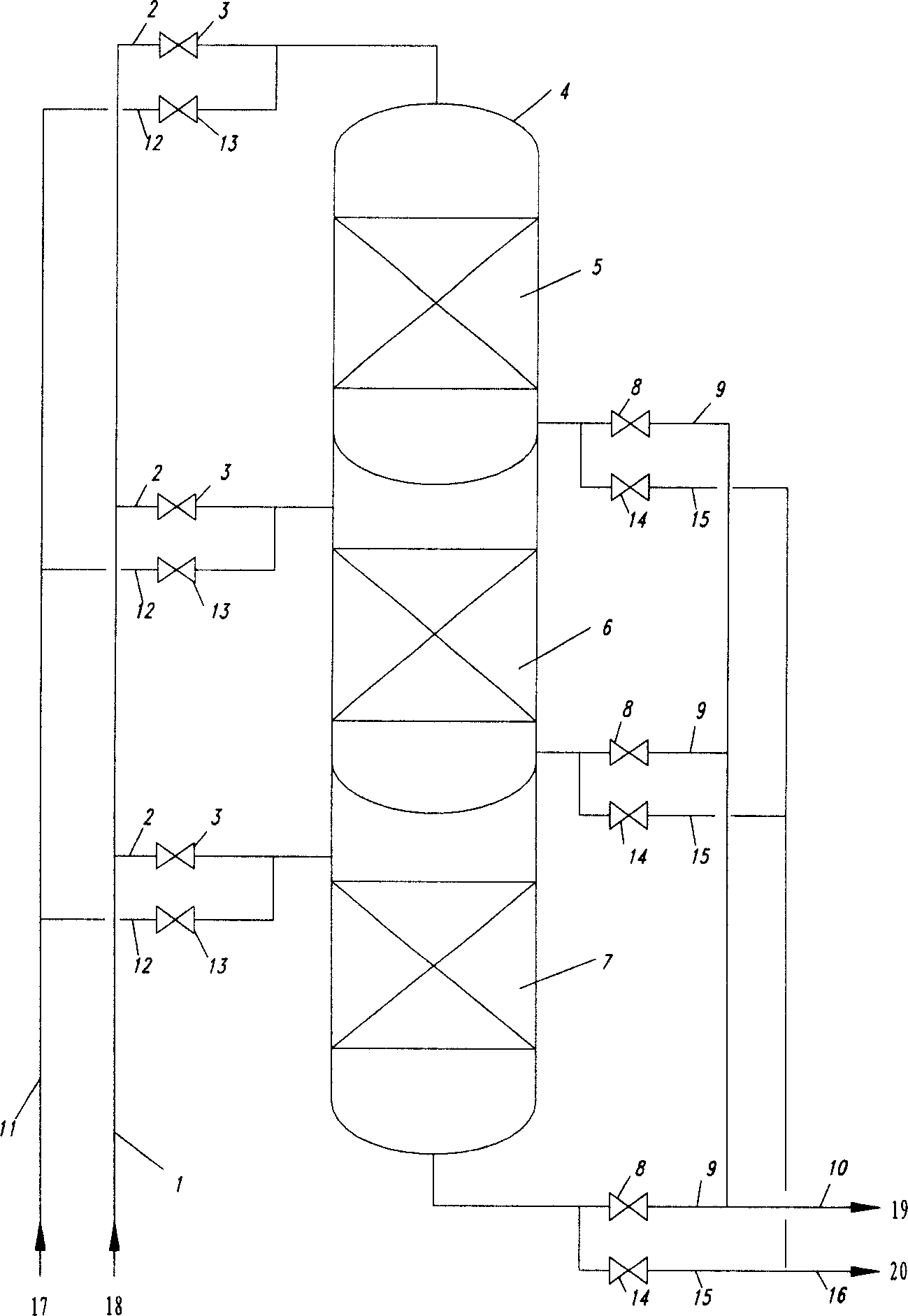

[0013] The process of producing propylene by catalytic cracking of olefins with carbon four and above is as follows: figure 1 In the switching continuous production process shown, the reactor includes three sections of fixed beds, two sections of fixed beds are used for reaction, and one section is used for regeneration. Reaction temperature 600°C, space velocity 14 hours -1 , normal pressure, catalyst life of 48 hours, that is, the reactor is switched once every 48 hours, each reactor is switched every 24 hours, and the molar ratio of silicon to aluminum (SiO 2 / Al 2 o 3 ) is a ZSM-5 type molecular sieve catalyst of 200, and the reaction raw material is ethylene plant etherified carbon four, and the composition of the initial stage and the final stage of the reaction product is shown in Table 1, and the propylene yield is 26.38~19.31%.

Embodiment 2

[0015] The process of producing propylene by catalytic cracking of olefins with carbon four and above is as follows: figure 1 In the switching continuous production process shown, the reactor includes four sections of fixed beds, three sections of fixed beds are used for reaction, and one section is used for regeneration. Reaction temperature 600°C, space velocity 14 hours -1 , normal pressure, catalyst life of 48 hours, that is, the reactor is switched once every 48 hours, each reactor is switched every 16 hours, and the molar ratio of silicon to aluminum (SiO 2 / Al 2 o 3 ) is a ZSM-5 type molecular sieve catalyst of 200, and the reaction raw material is carbon ether etherified in ethylene plant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com