Preparation method of gradient zirconium boride ultrahigh-temperature ceramic

A technology of ultra-high temperature ceramics and zirconium boride, which is applied in the field of preparation of ultra-high temperature ceramics, can solve the problems of poor toughness and thermal insulation performance of ultra-high temperature ceramics of zirconium boride, achieve good interface bonding, reduce heat conduction, and reduce residual heat. effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

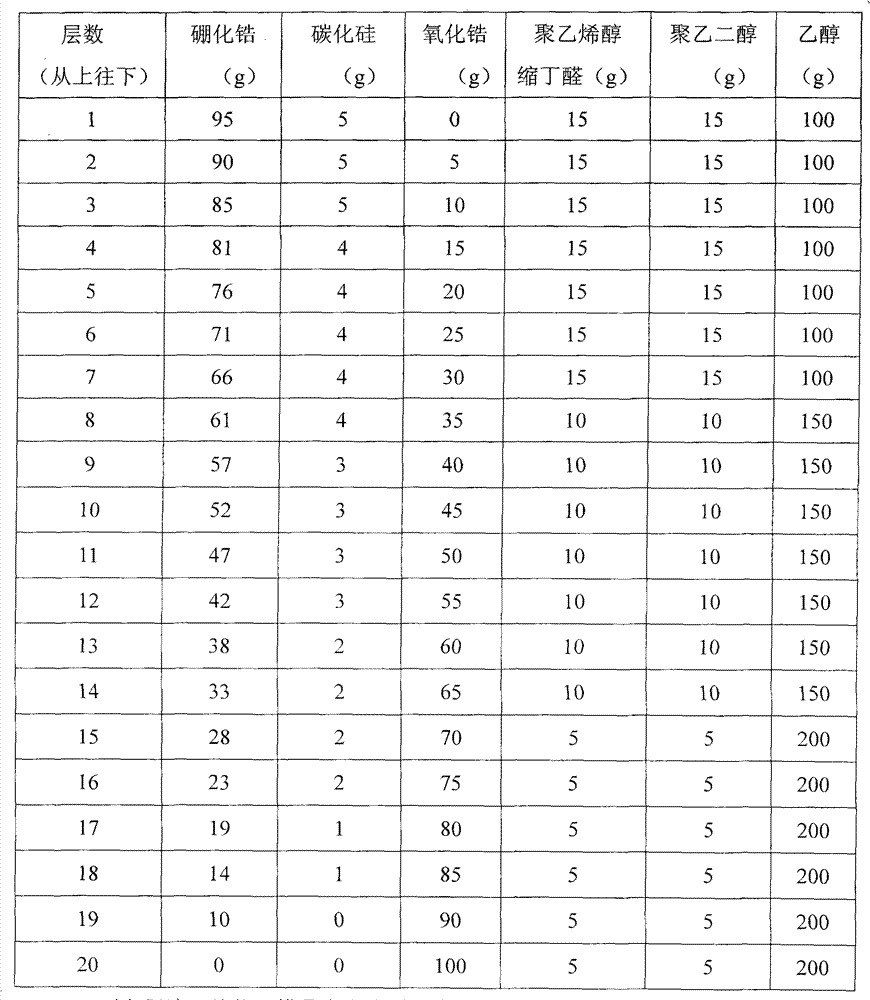

[0018] 1. Prepare casting sheets of 20 different components: first weigh polyvinyl butyral, polyethylene glycol, and ethanol according to the table below, stir evenly, and then add 1 μm zirconium boride powder and 0.5 μm silicon carbide The powder and nano-zirconia powder are stirred evenly to form casting materials of each layer; then the casting materials of each layer are cast separately, dried at room temperature and demolded to obtain cast sheets of each layer;

[0019]

[0020] 2. Slice each layer of cast sheet according to the size of the mold;

[0021] 3. Then, from top to bottom, stack each layer of cast sheets in the graphite abrasive tool in turn, and then vacuum degrease. When degreasing, the heating rate is 2°C / min, the temperature is raised to 600°C, and the temperature is kept for 1h;

[0022] 4. Then hot-press sintering in an argon atmosphere, the sintering temperature is 1800°C, the heat preservation time is 0.5h, and the pressure is 20MPa, and the gradient...

Embodiment 2

[0024] 1. Prepare casting sheets of 15 different components: first weigh polyvinyl butyral, polyethylene glycol, and ethanol according to the table below, stir evenly, and then add 2 μm zirconium boride powder and 1 μm silicon carbide powder 1. Stir the nano-zirconia powder evenly to form the cast material of each layer; then cast the cast material of each layer separately, dry and demould at room temperature to obtain the cast sheet of each layer;

[0025]

[0026] 2. Slice each layer of cast sheet according to the size of the mold;

[0027] 3. Then, from top to bottom, stack each layer of cast sheets in turn and put them into the graphite abrasive tool, and then vacuum degrease. When degreasing, the heating rate is 2.5°C / min, the temperature is raised to 700°C, and the temperature is kept for 1h;

[0028] 4. Then hot-press sintering in an argon atmosphere, the sintering temperature is 1850°C, the heat preservation time is 1h, and the pressure is 30MPa, and the gradient zi...

Embodiment 3

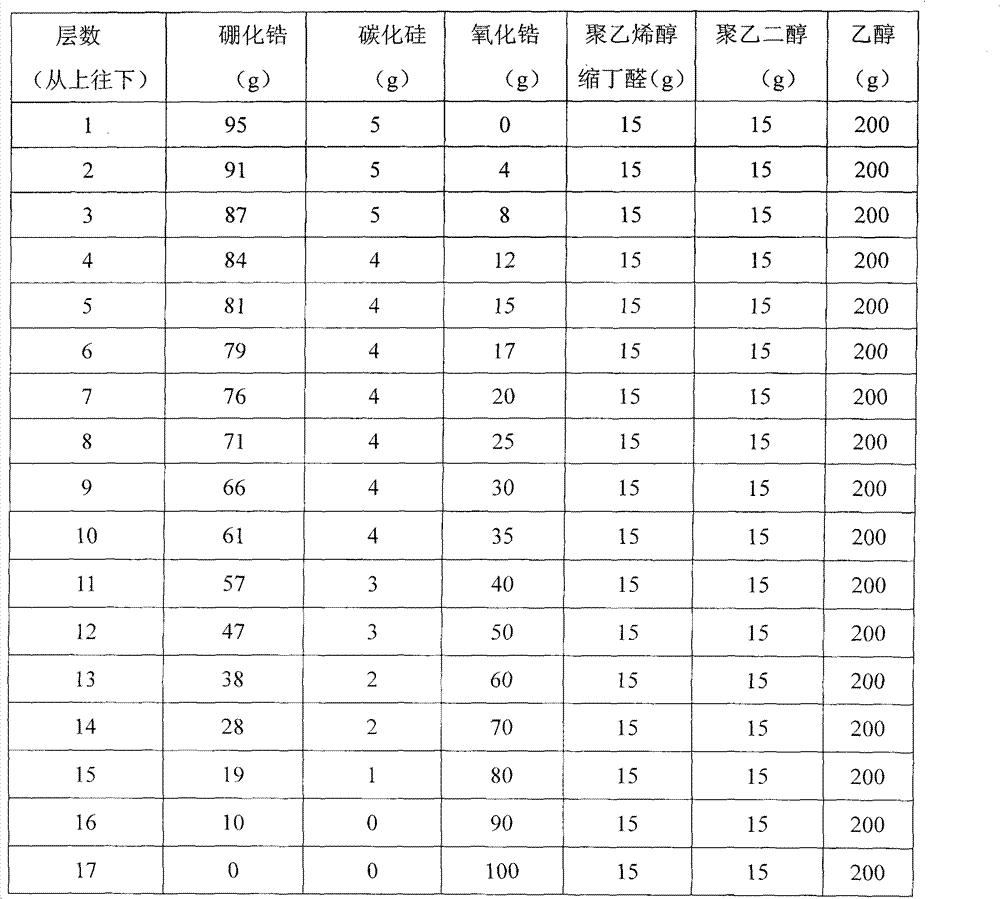

[0030] 1. Prepare casting sheets of 17 different components: first weigh polyvinyl butyral, polyethylene glycol, and ethanol according to the following table, stir evenly, and then add 5 μm zirconium boride powder and 2 μm silicon carbide powder 1. Stir the nano-zirconia powder evenly to form the cast material of each layer; then cast the cast material of each layer separately, dry and demould at room temperature to obtain the cast sheet of each layer;

[0031]

[0032] 2. Slice each layer of cast sheet according to the size of the mold;

[0033] 3. Then, from top to bottom, stack each layer of cast sheets in turn and put them into the graphite abrasive tool, and then vacuum degrease. When degreasing, the heating rate is 3°C / min, the temperature is raised to 650°C, and the temperature is kept for 1h;

[0034] 4. Then hot-press sintering in an argon atmosphere, the sintering temperature is 1900°C, heat preservation for 1 hour, and the pressure is 40MPa, and the gradient zirc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com