Method for preparing vertical anisotropic iron base soft magnetic film

A technology of perpendicular anisotropy and soft magnetic thin film, applied in the application of magnetic film to substrate, magnetic objects, magnetic materials, etc., can solve the problems of complex preparation and high cost, and achieve simple preparation process, low cost and small change Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

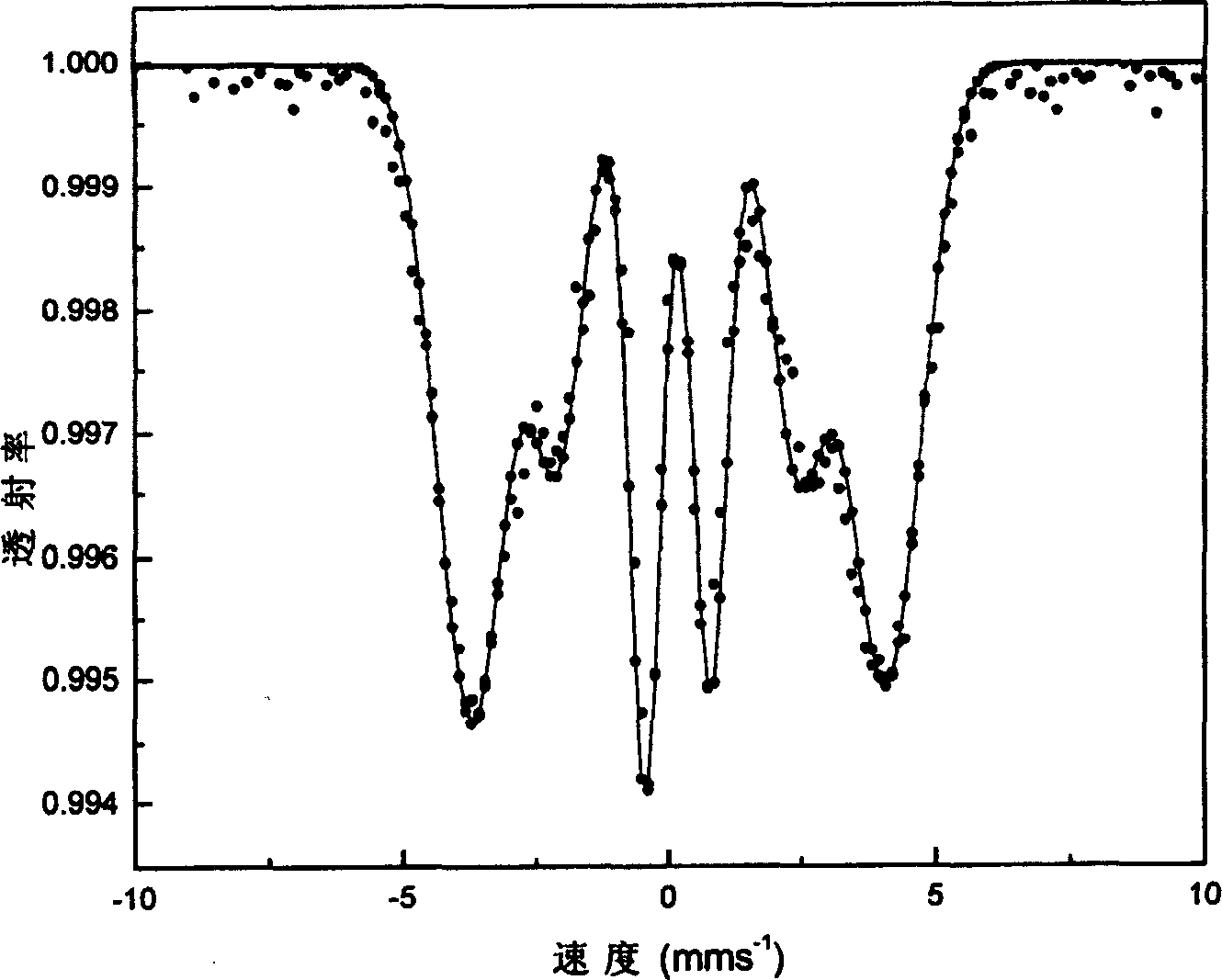

[0018] The target material is Fe 73.5 Cu 1 Nb 3 Si 13.5 B 9 During sputtering, the argon pressure and flow rate were 1.2Pa and 42ml / min respectively, the power was 120W, the film thickness was 2μm, annealing and heat treatment at 400°C for 30 minutes, and natural cooling under nitrogen atmosphere. The Mössbauer spectrum of the thin film sample is shown in figure 1 , the magnetic moment anisotropy of the thin film samples is mainly perpendicular to the film surface.

Embodiment 2

[0020] The target material is Fe 71 Cu 1 Cr 2 V 4 Si 13 B 9 During sputtering, the argon pressure and flow rate were 1.2Pa and 56ml / min respectively, the power was 200W, the film thickness was 3μm, annealing and heat treatment at 390°C for 20 minutes, and natural cooling in a nitrogen atmosphere under an external magnetic field. The magnetic moment anisotropy of the thin film samples is mainly perpendicular to the film plane.

Embodiment 3

[0022] The target material is Fe 73.5 Cu 1 Nb 3 Si 13.5 B 9 During sputtering, the argon pressure and flow rate were 1.2Pa and 28ml / min respectively, the power was 150W, the film thickness was 2.5μm, annealing and heat treatment at 400°C for 40 minutes, and natural cooling in a nitrogen atmosphere under an external magnetic field. The magnetic moment anisotropy of the thin film samples is mainly perpendicular to the film plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com