Method for preparing pulp for viscose fiber from hemp for seeds

A technology of viscose fiber and hemp, which is applied in the field of preparation of pulp for viscose fiber from hemp for seeds, can solve the problems of weakened moisture absorption and heat dissipation, adverse effects, and high content of metal ions, so as to improve the penetration ability and reduce the COD content, the effect of increasing the content of methyl fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

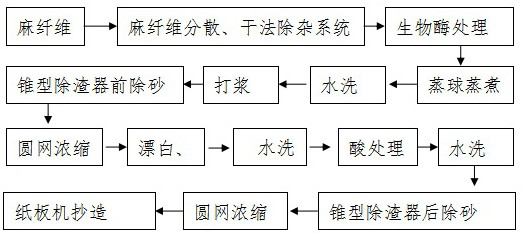

Image

Examples

Embodiment 1

[0041] Embodiment 1: A kind of preparation method of pulp for viscose fiber is prepared with hemp for seed, and this preparation method comprises the following steps:

[0042] 1) Material selection, cotton opening, and dry impurity removal: select 100% degummed hemp for seeds, use cotton opener to tear hemp for seeds, and use impurity remover to select and remove impurities, and then separate them by cyclone The machine is sent to the screw press and impregnation.

[0043] In the step 1), tear the material according to the requirement that the feeding thickness is ≤10cm and put it into the cotton opener, the feeding time of each basic unit is ≥60min, and then two sets of five-roller cleaning machines connected in series are fully opened, Make the slurry output by the impurity remover pass sequentially; then send it to the screw press and impregnate through the cyclone separator.

[0044]The purpose of the step 1) is to reduce the content of COD in the cooking black liquor and...

Embodiment 2

[0075] A preparation method for preparing pulp for viscose fiber from hemp for seeds, the preparation method comprising the following steps:

[0076] 1) Material selection, cotton opening, and dry impurity removal: select 100% degummed hemp for seeds, use cotton opener to tear hemp for seeds, open cotton and feed thickness ≤ 10cm, feeding time: ≥ 60min, and use The impurity removal machine selects and removes impurities, among which the five-roller cleaning machine is fully opened in two lanes, and then sent to the screw press and impregnation through the cyclone separator.

[0077] The purpose of the step 1) is to reduce the content of COD in the cooking black liquor and increase the content of methylcellulose.

[0078] 2) Alkali blending and impregnation: When blending alkali, control the temperature of alkali blending at 70°C, and the concentration of alkali blending is 50g / L. Before measuring the alkali concentration, it is necessary to circulate the alkali solution for a ...

Embodiment 3

[0098] A preparation method for preparing pulp for viscose fiber from hemp for seeds, the preparation method comprising the following steps:

[0099] 1) Material selection, cotton opening, and dry impurity removal: select 100% degummed hemp for seeds, use cotton opener to tear hemp for seeds, open cotton and feed thickness ≤ 10cm, feeding time: ≥ 60min, and use The impurity removal machine selects and removes impurities, among which the five-roller cleaning machine is fully opened in two lanes, and then sent to the screw press and impregnation through the cyclone separator.

[0100] The purpose of the step 1) is to reduce the content of COD in the cooking black liquor and increase the content of methylcellulose.

[0101] 2) Alkali blending and impregnation: When blending alkali, control the temperature of alkali blending at 80°C, and the concentration of alkali blending is 54g / L. Before measuring the alkali concentration, it is necessary to circulate the alkali solution for a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com