Beta-CD gemini viscoelastic surfactant, preparation method and temperature-resistant and salt-resistant clean fracturing fluid

A surfactant, cleaning fracturing fluid technology, applied in chemical instruments and methods, dissolution, drilling composition, etc., to achieve the effect of excellent temperature resistance and shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

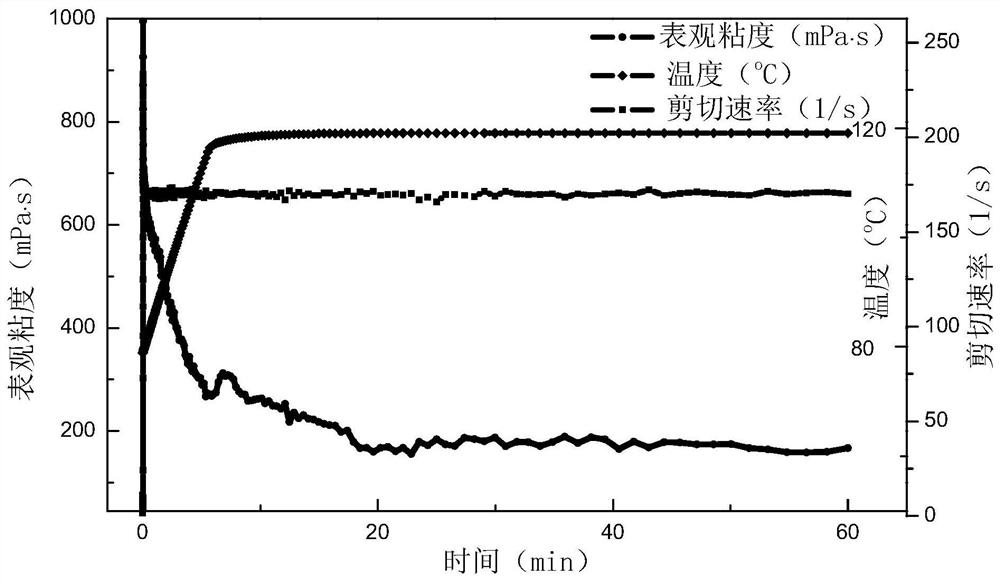

Embodiment 1

[0043] A kind of β-CD gemini viscoelastic surfactant, its structural formula is:

[0044]

[0045] The preparation method of above-mentioned β-CD gemini viscoelastic surfactant, comprises the following steps:

[0046] (1) Preparation of mono-6-p-toluenesulfonyl-β-cyclodextrin (6-OTs-β-CD)

[0047] Take a 250mL beaker and suspend 50g (44.1mmol) of β-cyclodextrin in a mixture of 100mL of ethanol and water (volume ratio 5:1) by magnetic stirring under ice-salt bath conditions, and dissolve 16.7mL of sodium hydroxide solution (8.5mol / L) was slowly dropped into the β-cyclodextrin suspension, and the suspension became clear. Then 25.22g (132.3mmol) of p-toluenesulfonyl chloride (p-TsCl) was dissolved in acetonitrile solution and dropped into the above sodium hydroxide solution of cyclodextrin. After the dropwise addition, the reaction was continued at 22°C for 2 hours. After the reaction, the unreacted p-TsCl was filtered off with suction, and the filtrate was neutralized with di...

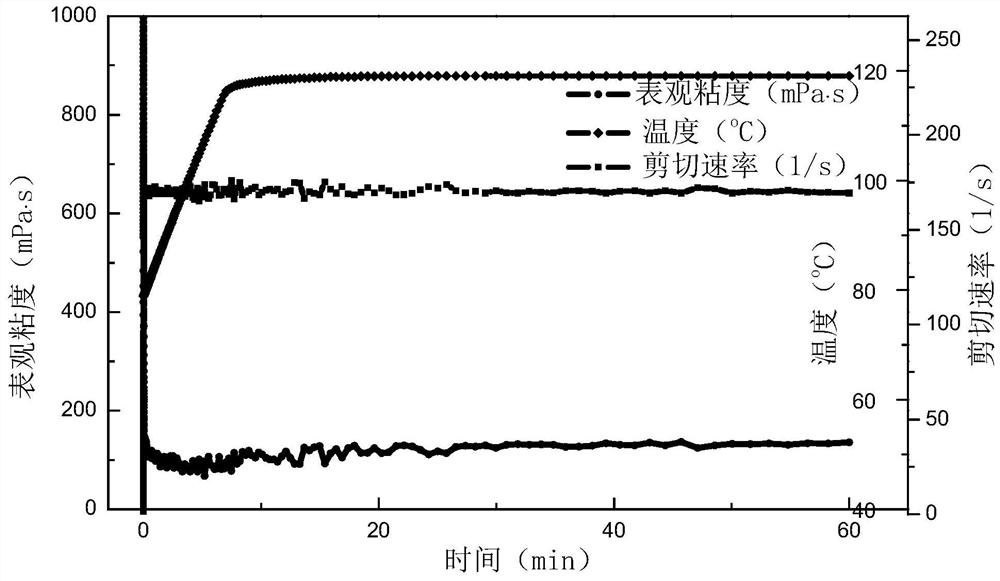

Embodiment 2

[0061] A kind of β-CD gemini viscoelastic surfactant, its structural formula is:

[0062]

[0063] The preparation method of above-mentioned β-CD gemini viscoelastic surfactant, comprises the following steps:

[0064] (1) Preparation of mono-6-p-toluenesulfonyl-β-cyclodextrin (6-OTs-β-CD)

[0065] Take a 250mL beaker and suspend 50g (44.1mmol) of β-cyclodextrin in a mixture of 100mL of ethanol and water (volume ratio 5:1) by magnetic stirring under ice-salt bath conditions, and dissolve 16.7mL of sodium hydroxide solution (8.5mol / L) was slowly dropped into the β-cyclodextrin suspension, and the suspension became clear. Then 25.22g (132.3mmol) of p-toluenesulfonyl chloride (p-TsCl) was dissolved in acetonitrile solution and dropped into the above sodium hydroxide solution of cyclodextrin. After the dropwise addition, the reaction was continued at 22°C for 2 hours. After the reaction, the unreacted p-TsCl was filtered off with suction, and the filtrate was neutralized with ...

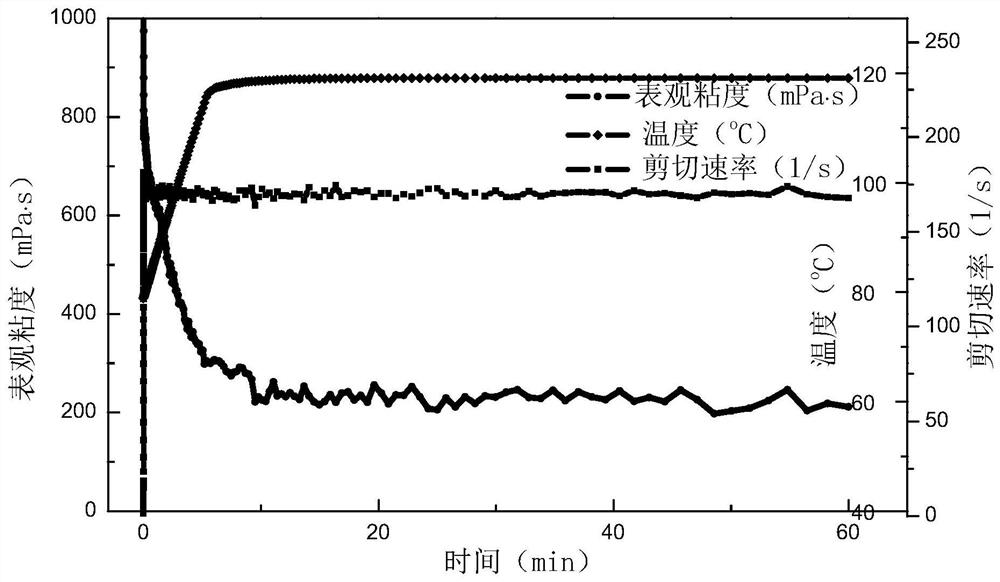

Embodiment 3

[0079] A kind of β-CD gemini viscoelastic surfactant, its structural formula is:

[0080]

[0081] The preparation method of above-mentioned β-CD gemini viscoelastic surfactant, comprises the following steps:

[0082] (1) Preparation of mono-6-p-toluenesulfonyl-β-cyclodextrin (6-OTs-β-CD)

[0083] Take a 250mL beaker and suspend 50g (44.1mmol) of β-cyclodextrin in a mixture of 100mL of ethanol and water (volume ratio 5:1) by magnetic stirring under ice-salt bath conditions, and dissolve 16.7mL of sodium hydroxide solution (8.5mol / L) was slowly dropped into the β-cyclodextrin suspension, and the suspension became clear. Then 25.22g (132.3mmol) of p-toluenesulfonyl chloride (p-TsCl) was dissolved in acetonitrile solution and dropped into the above sodium hydroxide solution of cyclodextrin. After the dropwise addition, the reaction was continued at 22°C for 2 hours. After the reaction, the unreacted p-TsCl was filtered off with suction, and the filtrate was neutralized with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com