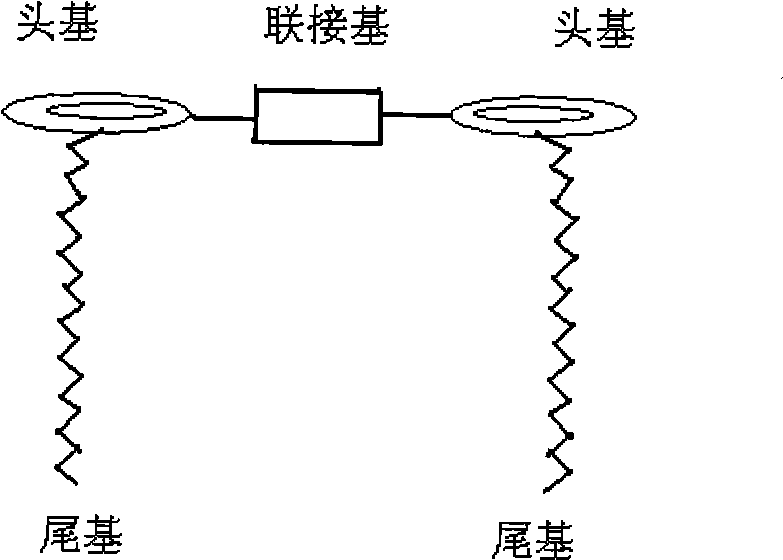

Aqueous water-and-oil repellant dispersion composition

A technology of water-based dispersion liquid and waterproof and oil-repellent agent, which can be used in textiles, papermaking, fiber treatment, etc., and can solve problems such as poor mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

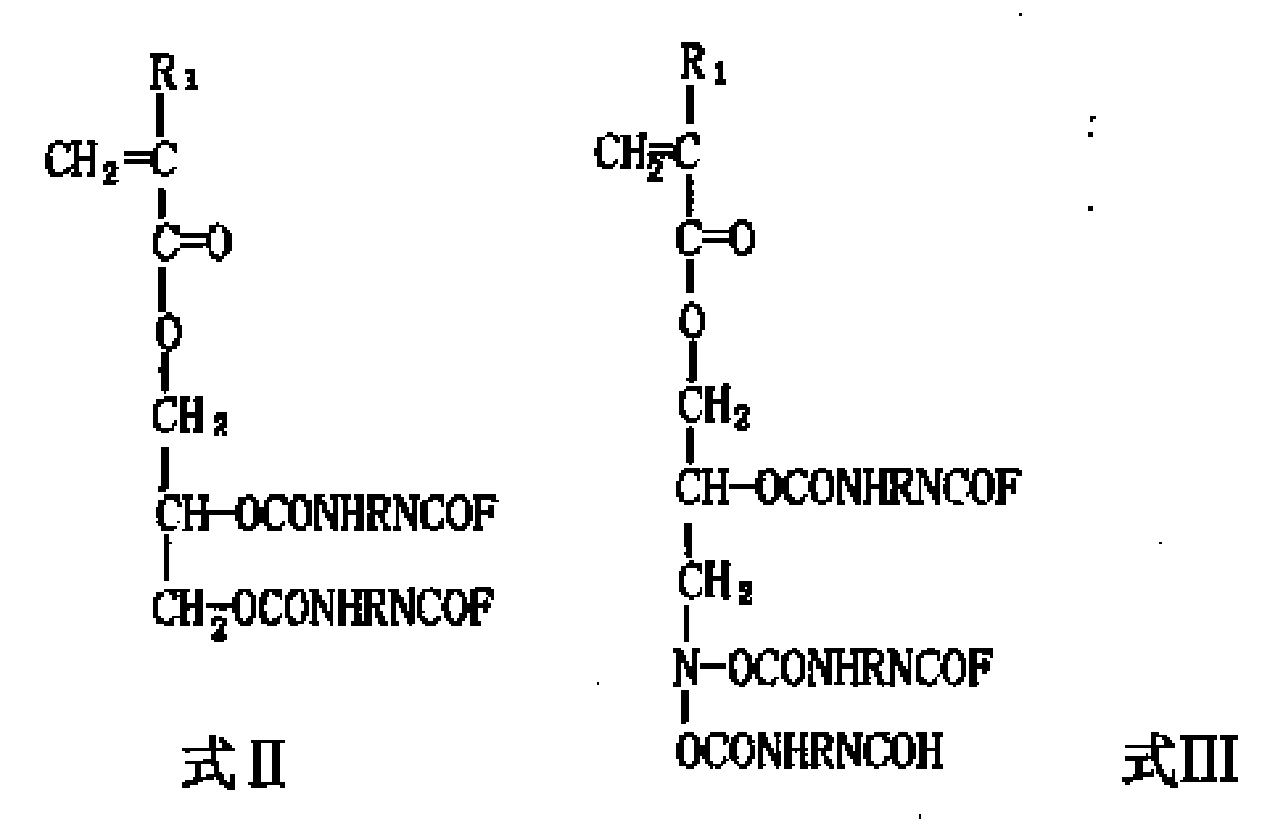

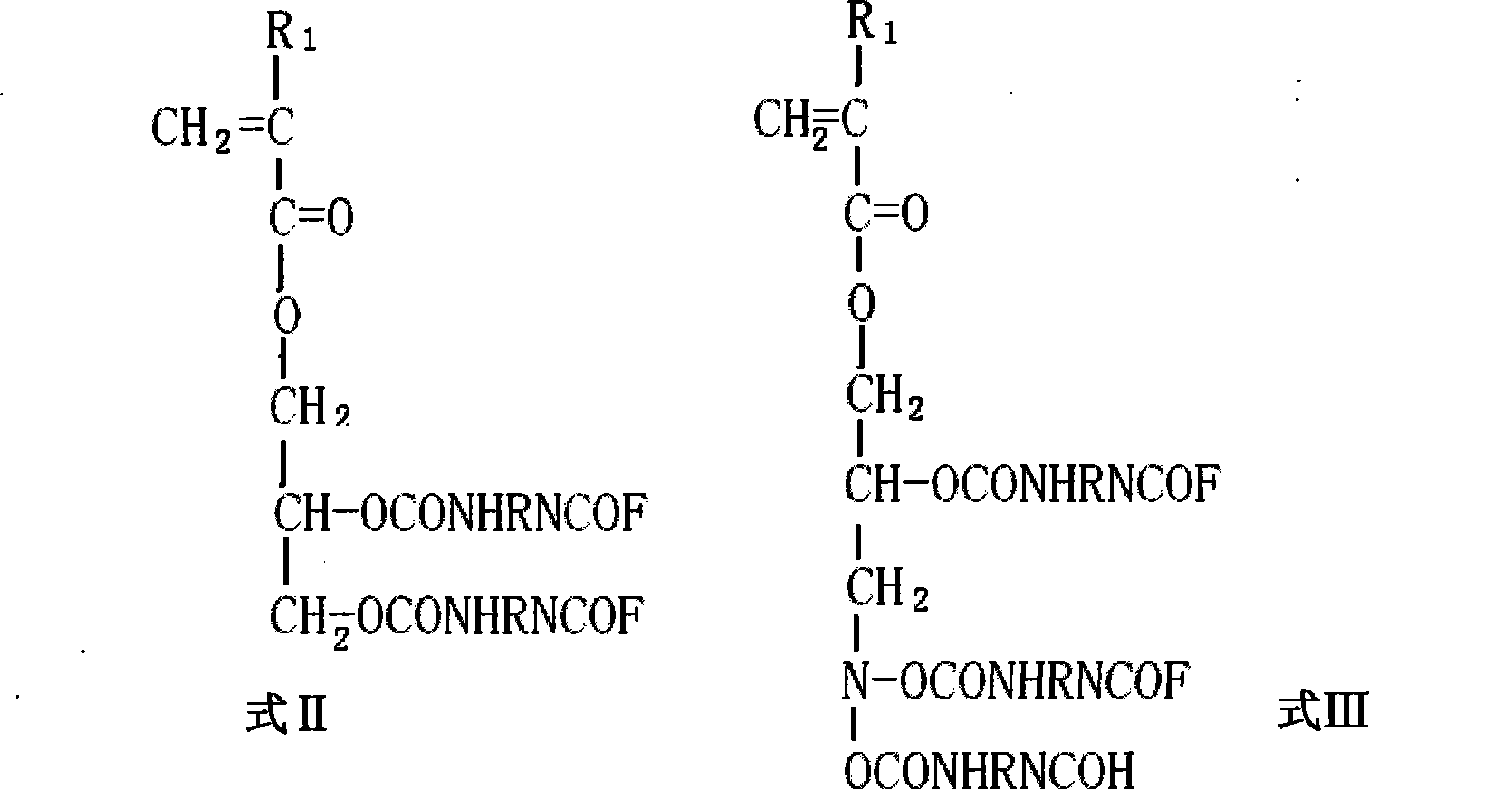

[0077] In a 5L glass three-necked flask, add Gemini surfactant 12-2-1215g, alkyl allyl polyoxyethylene propyl ether 72g, Pingpingjia 0-1513g, dipropylene glycol 280g, deionized water 2100g. The above-mentioned material is heated to 49~51 ℃ by brine bath method, and keeps the temperature within this range. Then add perfluoroalkyl ethyl methacrylate - referred to as FMA, its molecular formula is CF 3 CF 2 (CF 2 CF 2 )nCH 2 CH 2 OCO(CH 3 )=CH 2 , wherein n=2~6, 5.88g, 124g of octadecyl methacrylate, 150g of 2-ethylethyl methacrylate, 50g of hydroxyethyl methacrylate, referred to as GTMA containing 2 blocked polyisocyanates 68g of methacrylic ester of acid group, its molecular structure is shown in formula VI, n-dodecyl mercaptan 3.2g. After feeding the material, start the mixer to stir the material, emulsify for 30 minutes, transfer to a 6-liter stainless steel bucket, pass through a high-speed shear disperser, shear and disperse at a high speed of 5000rpm for 15 minutes,...

Embodiment 2

[0080] In a 5L glass three-neck flask, add Gemini surfactant 12-2-12 15g, alkyl allyl polyoxyethylene propyl ether 72g, Pingpingjia 0-20 13g, dipropylene glycol 280g, deionized water 2100g. The above-mentioned material is heated to 49~51 ℃ by brine bath method, and keeps the temperature within this range. Then add perfluoroalkyl ethyl methacrylate - referred to as FMA, its molecular formula is CF 3 CF 2 (CF 2 CF 2 )nCH 2 CH 2 OCO(CH 3 )=CH 2 , where n=2~6, 5.88g, 124g of octadecyl methacrylate, 50g of N-methylolacrylamide, 150g of 2-ethylethyl methacrylate, referred to as GIMA containing 2 blocked polyiso 68g of methacrylic acid ester of cyanate group, its molecular structure is shown in formula VII, n-dodecanethiol 3.2g. After feeding the material, start the mixer to stir the material, emulsify for 30 minutes, transfer to a 6-liter stainless steel bucket, pass through a high-speed shear disperser, shear and disperse at a high speed of 5000rpm for 15 minutes, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com