Crosslinking fluorine modified acrylic ester nanometer polymer emulsion and preparation method thereof

A nano-polymer and acrylate technology, applied in coatings and other directions, can solve the problems of restricting the development of fluorocarbon nano-polymer emulsions, affecting the excellent properties of fluorocarbon nano-polymer emulsions, and restricting the application of microemulsions, and achieving low critical glue Beam concentration, excellent hydrophobicity, fine appearance effect

Active Publication Date: 2013-05-08

安吉万国涂料有限公司

View PDF6 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The above defects limit the industrial application of microemulsions, and affect the excellent performance of fluorocarbon nanopolymer emulsions, which limits the further development of fluorocarbon nanopolymer emulsions

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0035] Example 2

Embodiment 2

[0037] Example 3

Embodiment 3

[0039] Example 4

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

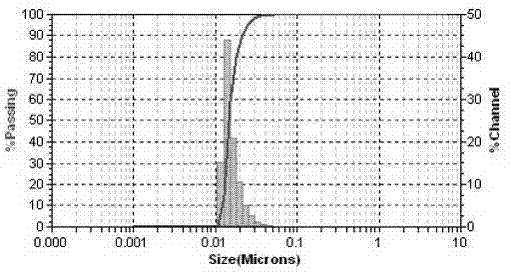

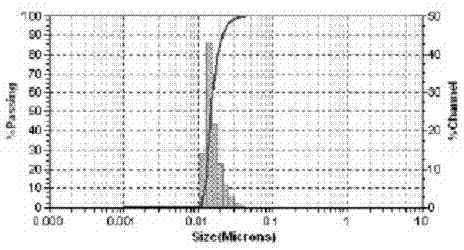

| particle diameter | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Login to View More

Abstract

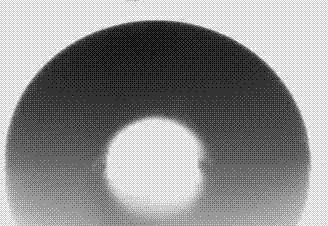

The invention relates to crosslinking fluorine modified acrylic ester nanometer polymer emulsion and a preparation method thereof. The crosslinking fluorine modified acrylic ester nanometer polymer emulsion is prepared from the following six main components through half-continuous seed emulsion polymerization, wherein in the six main components, a fluorine monomer accounts for 10-25 percent of the whole monomer mass, an acrylic ester monomer accounts for 20-30 percent of the whole monomer mass, a metacrylic ester monomer accounts for 10-25 percent of the whole monomer mass, 4) crosslinking monometer methacrylic acid hydroxyalkyl ether accounts for 5-10 percent of the whole monomer mass, 5) a dimeric surfactant accounts for 1.5-3.5 percent of the whole monomer mass, and 6) a water-soluble azo initiator accounts for 1-3 percent of the whole monomer mass. The crosslinking fluorine modified acrylic ester nanometer polymer emulsion has the advantage that a latex film is high in hydrophobicity, weather resistance, chemical resistance and high-temperature resistance after nano emulsion is subjected to film formation.

Description

technical field [0001] The invention relates to a cross-linked fluorine-modified acrylate nanometer polymer emulsion and a preparation method thereof. The polymer emulsion can be used in the fields of coatings, adhesives, finishing agents, leather finishing agents and the like. Background technique [0002] The fluorine-containing acrylate polymer emulsion not only retains the good film-forming properties and adhesion of the polyacrylate emulsion, but also has the excellent performance of the fluorine-containing polymer to a certain extent, showing hydrophobic, oleophobic and anti-fouling surface characteristics. It is widely used in the fields of high performance coating, textile finishing, leather and packaging. The fluorocarbon nanopolymer emulsion also has the following unique advantages: good permeability and wettability, strong adhesion to the substrate; small particle size, can form a dense coating film, and the formed coating film has high gloss; The particle size ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08F220/18C08F220/14C08F220/22C08F2/28C08F4/04C09D133/08

Inventor 邵毅江惠建伟梁军

Owner 安吉万国涂料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com