Preparation of sulfonic acid amphoteric double-ion viscoelastic surfactant and application in fracturing fluid

A technology of surfactant and viscoelasticity, which is applied in the field of preparation of sulfonic acid amphoteric gemini viscoelastic surfactants, can solve the problems of temperature resistance and salt resistance performance limiting further application, and achieve the effect of excellent temperature resistance and shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) First, dissolve 100mmol of erucamidopropyldimethylamine in a 500mL single-necked round bottom flask containing 150mL of isopropanol, then add 110mmol of epichlorohydrin into the round bottom flask, and stir at 80°C for 12h , after the reaction is over, the intermediate DNPC is obtained.

[0033] (2) Add 50mmol of sodium p-aminobenzenesulfonate and 200mL of distilled water to the intermediate DNPC obtained in the first step, and react at 90°C for 24h, and remove the solvent with a rotary evaporator after the reaction to obtain a light yellow viscous Thick liquid, that is, sulfonic acid amphoteric gemini viscoelastic surfactant VBS.

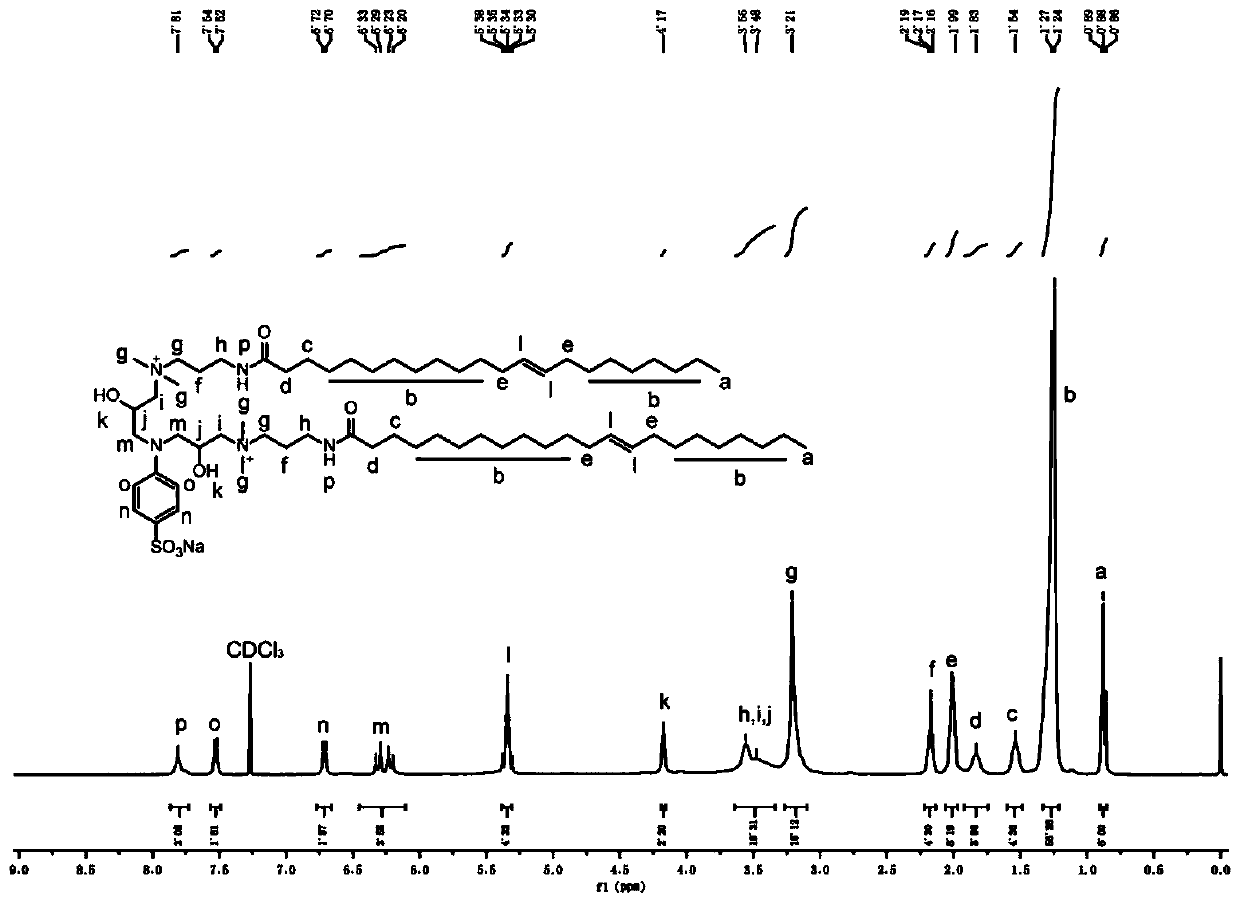

[0034] (3) The H NMR spectrum of sulfonic acid amphoteric gemini viscoelastic surfactant VBS is attached figure 1 shown.

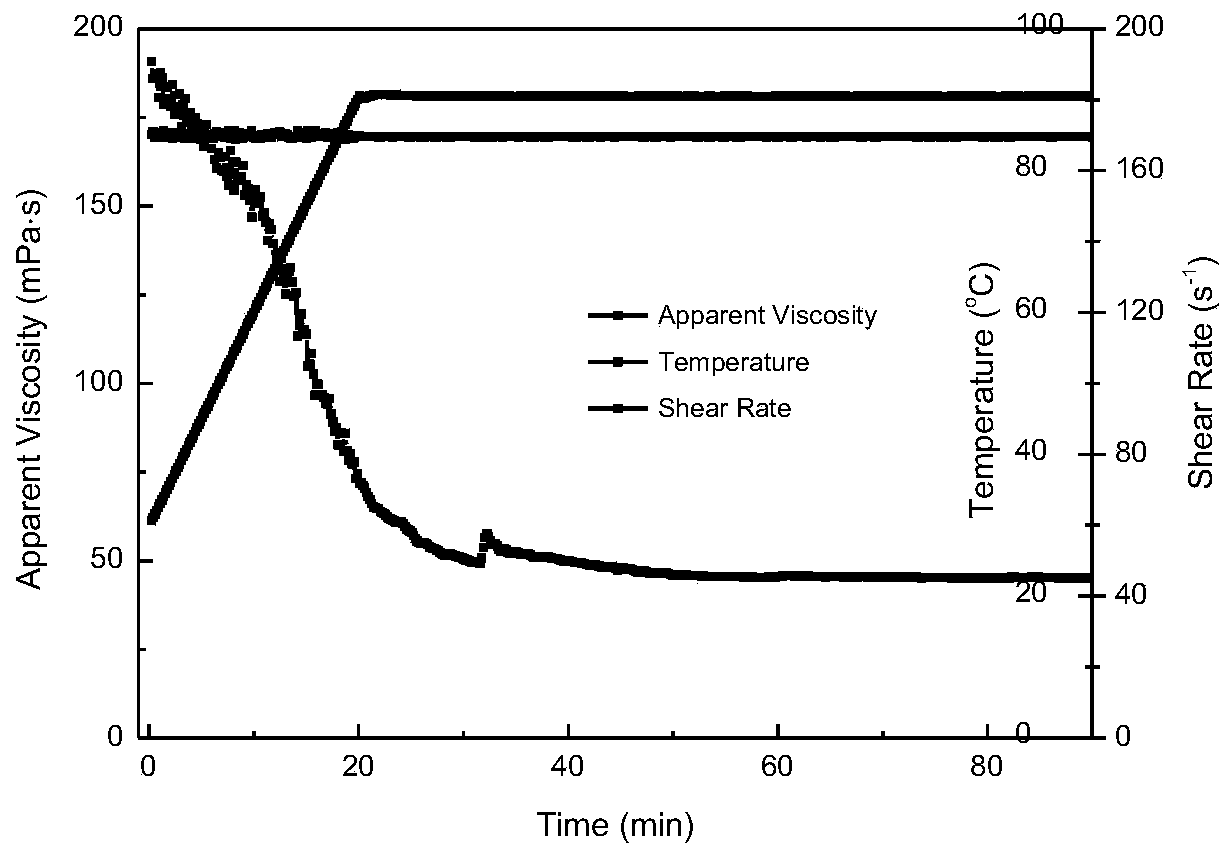

[0035] (4) The clean fracturing fluid system composed of 20mmol / L sulfonic acid amphoteric gemini viscoelastic surfactant VBS and 120mmol / L NaSal was heated at 90°C for 170s. -1 After shearing for 90 minutes, the ...

Embodiment 2

[0037] (1) First, dissolve 100mmol of erucamidopropyldimethylamine in a 500mL single-necked round-bottomed flask containing 200mL of ethanol, then add 140mmol of epichlorohydrin to the round-bottomed flask, stir at 80°C for 12h, and react After the end, the intermediate DNPC is obtained.

[0038] (2) Add 48 mmol of sodium p-aminobenzenesulfonate and 200 mL of distilled water to the intermediate DNPC obtained in the first step, and react at 80° C. for 18 h, and remove the solvent with a rotary evaporator after the reaction to obtain a light yellow viscous Thick liquid, that is, sulfonic acid amphoteric gemini viscoelastic surfactant VBS.

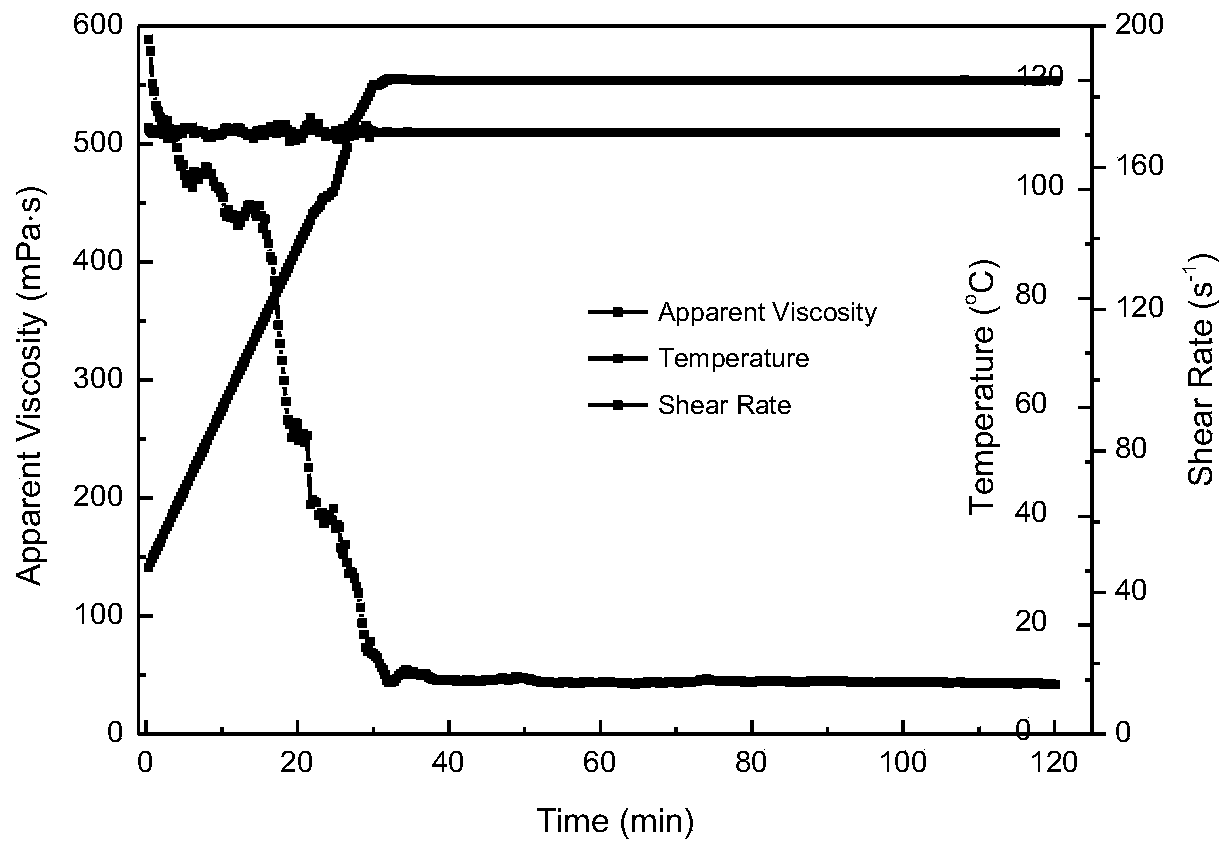

[0039] (3) The clean fracturing fluid system composed of 30mmol / L sulfonic acid amphoteric gemini viscoelastic surfactant VBS and 120mmol / L NaSal was heated at 120°C for 170s. -1 After shearing for 90 minutes, the viscosity can be maintained above 25mPa·s. image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com