Soap-free emulsion polymerization method of polyvinylidene fluoride for lithium battery electrode binding agent

A technology of soap-free emulsion polymerization and polyvinylidene fluoride, which is applied in the field of polymers, can solve the problems of affecting the electrical properties of polymers, increasing process complexity, and increasing costs, and achieves high stability, low manufacturing cost, and high adhesion sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

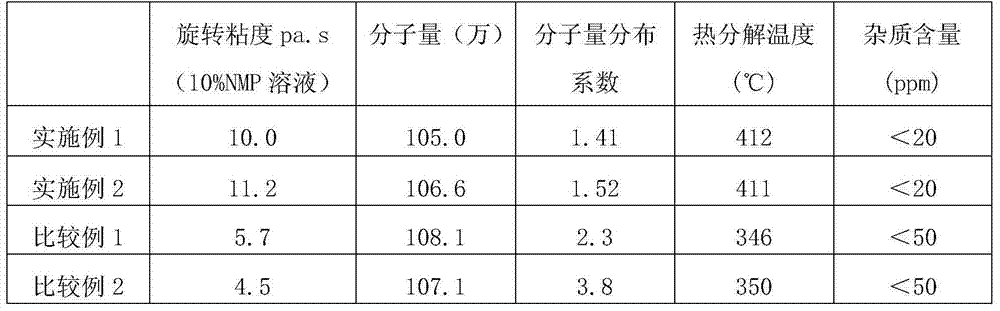

Examples

Embodiment 1

[0030] Example 1: Add 6.5 kg of ion-free water, 0.5 kg of fluorocarbon solvent, and 50 g of ammonium hydrogen phosphate solution with a mass concentration of 10% into a cleaned 10L polymerization kettle as a pH buffer; evacuate and remove oxygen until the oxygen content is ≤ 20ppm It is qualified; prepare a total of 100g of ammonium persulfate aqueous solution (initiator) with a mass concentration of 2.0%, and 200g of ethyl acetate solution with a mass concentration of 3.0% (regulator), and set aside. The monomer vinylidene fluoride in the storage tank is 5kg. Then raise the temperature of the polymerization kettle, and at the same time, increase the pressure by filling the polymerization kettle with vinylidene fluoride monomer. When the temperature of the polymerization kettle reaches 85°C and the pressure of the kettle reaches 2.0MPa, quickly inject 30g of 2.0% vinylidene fluoride into the polymerization kettle with a metering pump. Aqueous solution of ammonium persulfate, s...

Embodiment 2

[0031]Example 2: Taking a 10L polymerization kettle as an example, add 6.5kg of ion-free water, 0.5kg of fluorocarbon solvent, and 50g of pH buffering agent to a 10% ammonium hydrogen phosphate solution in the cleaned polymerization kettle; Content ≤ 20ppm is qualified; prepare a total of 80g of ammonium persulfate aqueous solution (initiator) with a mass concentration of 2.5%, and 200g of ethyl acetate solution with a mass concentration of 3.0% (regulator) for later use. Then raise the temperature of the polymerization kettle, and increase the pressure by filling the polymerization kettle with vinylidene fluoride monomer at the same time. When the temperature of the polymerization kettle reaches 85°C and the pressure of the kettle reaches 2.0MPa, quickly inject 24g of 2.5% superfluidic acid into the polymerization kettle with a metering pump. Ammonium sulfate aqueous solution, start polyreaction, after 15 minutes, squeeze remaining 56g concentration with metering pump at a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com