Carbomer and preparation method thereof

An acrylic and monomer technology, applied in the field of carbomer and its preparation, can solve the problems of low production efficiency, limited swelling conditions, long wetting time and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

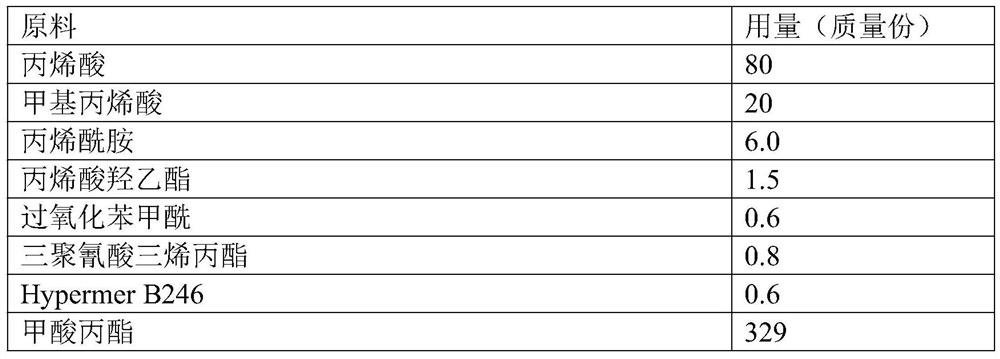

[0031] A kind of carbomer, its raw material formula composition is as table 1:

[0032] Table 1

[0033] raw material Dosage (parts by mass) acrylic acid 100 Acrylamide 5.0 Hydroxyethyl Acrylate 2.0 Benzoyl peroxide 0.6 Triallyl cyanurate 0.6 Hypermer B246 0.4 Propyl formate 429 n-Hexane 571

[0034] The method steps for preparing carbomer by adopting the raw material combination of the carbomer are:

[0035] (1) Weigh the mixed solvent at 1 g per part by mass, mix it evenly, add it to the reaction kettle, turn on the electric stirring, and heat the reaction kettle to 80-85°C and keep it warm;

[0036] (2) After mixing the mixed monomer (acrylic acid monomer, acrylamide, hydroxyethyl acrylate), crosslinking agent, initiator and stabilizer evenly, to obtain solution A, the reactor is provided with a high-level tank, and the high-level tank Add solution A to the reactor, add solution A dropwise to the reactor, and ...

Embodiment 2

[0042] A kind of carbomer, its raw material formula composition is as table 2:

[0043] Table 2

[0044] raw material Dosage (parts by mass) acrylic acid 100 Acrylamide 5.0 Hydroxyethyl Acrylate 2.0 Benzoyl peroxide 0.6 Allyl Sucrose Ether 0.6 Hypermer B246 0.4 Propyl formate 429 n-Hexane 571

[0045] The method steps of preparing the carbomer by using the raw material combination of the carbomer are the same as in Example 1.

[0046] The prepared carbomer is formulated into a 0.5% carbomer aqueous solution with a mass fraction of 0.5%, and the wetting time is 189s, and then the pH value of the 0.5% carbomer aqueous solution is adjusted to 6.8-7.5 with a 15% mass fraction of NaOH solution, The measured viscosity is 5500mPa·s.

[0047] Weigh 1.0 g of the carbomer prepared in this example and add it to 200.0 g of 80v / v% ethanol aqueous solution to observe the swelling of the carbomer. After 6 hours, it was found that...

Embodiment 3

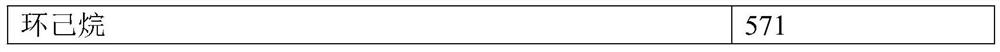

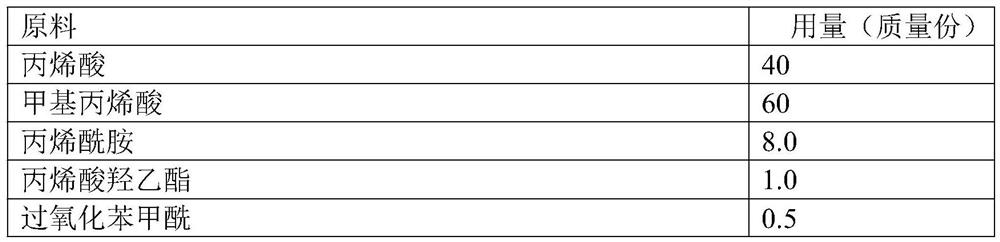

[0049] A kind of carbomer, its raw material formula composition is as table 3:

[0050] table 3

[0051]

[0052]

[0053] The method steps of preparing the carbomer by using the raw material combination of the carbomer are the same as in Example 1.

[0054] The prepared carbomer is formulated into a 0.5% carbomer aqueous solution with a mass fraction of 0.5%, and the wetting time is 152s, and then the pH value of the 0.5% carbomer aqueous solution is adjusted to 6.8-7.5 with a 15% mass fraction of NaOH solution, The measured viscosity is 25000mPa·s.

[0055] Weigh 1.0 g of the carbomer prepared in this example and add it to 200.0 g of 80v / v% ethanol aqueous solution to observe the swelling of the carbomer. After 6 hours, it was found that all the carbomer swelled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com