Quantum dot ink and preparation method thereof

A technology of quantum dots and quantum dot solution, applied in the field of quantum dot luminescence, can solve the problems of low viscosity, inconsistent quantum dot film thickness, poor uniformity, etc., and achieve the effects of uniform film formation, controllable composition ratio, and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] And, the embodiment of the present invention provides a method for preparing quantum dot ink, including the following steps:

[0059] S01. Weigh the formula components of the quantum dot ink of the foregoing claims;

[0060] S02. Dissolve the quantum dots in a solvent to form a quantum dot solution;

[0061] S03. Adding a viscosity modifier to the quantum dot solution, and mixing processing to obtain a quantum dot ink.

[0062] In the above step S01, the formula of the quantum dot ink and its preferred components and contents have been stated above. In order to save space, the details will not be repeated here.

[0063] In the above step S02, the quantum dots are dissolved in a solvent to form a quantum dot solution. Preferably, the quantum dots are dispersed in the main solvent, that is, a non-polar solvent, to better disperse the quantum dots uniformly, and then add The co-solvent is uniformly mixed to obtain a uniformly dispersed quantum dot solution. Among them, the method ...

Embodiment 1

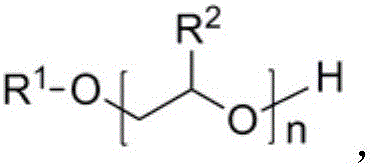

[0082] A quantum dot ink, based on the weight percentage of the quantum dot ink as 100%, contains the weight percentage components shown in Example 1 of Table 1 below, wherein the quantum dots are oleylamine stable For red CdSe / ZnS quantum dots, the viscosity modifier is a viscosity modifier whose structure is shown in the following structural formula I, the main solvent is high-purity chlorobenzene, and the co-solvent is toluene.

[0083]

[0084] The method for preparing the quantum dot ink includes the following steps: weighing the formula components of the quantum dot ink; adding quantum dots, high-purity chlorobenzene, toluene and a viscosity modifier in order to form a blend, and combining the The mixture was stirred and mixed for 30 minutes to obtain a quantum dot ink composition.

[0085] Further, the quantum dot ink is printed by an inkjet printer into a quantum dot layer of 20×30 um and a resolution of 200×200 ppi. Heat to 200℃, 1×10 on the hot plate -6 Volatilize and dr...

Embodiment 2

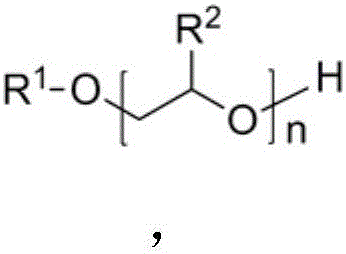

[0087] Three kinds of quantum dot inks, based on the weight percentage of the quantum dot ink as 100%, contain the components shown in the following table 1 and embodiment 2 in weight percentage, wherein the quantum dots are oleylamine stable quantum Point, the viscosity modifier is a viscosity modifier whose structure is shown in the following structural formula II, the main solvent is high-purity n-heptane, and the co-solvent is o-xylene.

[0088]

[0089] Among them, the quantum dots in the first quantum dot ink are blue CdS / CdZnS quantum dots, the quantum dots in the second quantum dot ink are green CdZnSe / CdZnS quantum dots, and the quantum dots in the third quantum dot ink are red CdSe / ZnS quantum dots.

[0090] The method for preparing the quantum dot ink includes the following steps: weighing the formula components of the quantum dot ink; adding quantum dots, high-purity n-octane, toluene and a viscosity modifier in order to form a blend, and adding The blend was stirred ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com