Preparing method for multi-scale nano particle interlayer toughening composite material

A technology for toughening composite materials and micro-nano particles, applied in the field of composite materials, can solve the problems of thermal properties, other mechanical properties, unfavorable RTM molding, etc., and achieve the effects of low cost, no loss of thermal properties, and simple modification principle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing a multi-scale micro-nano particle interlayer toughened composite material, the steps of which are:

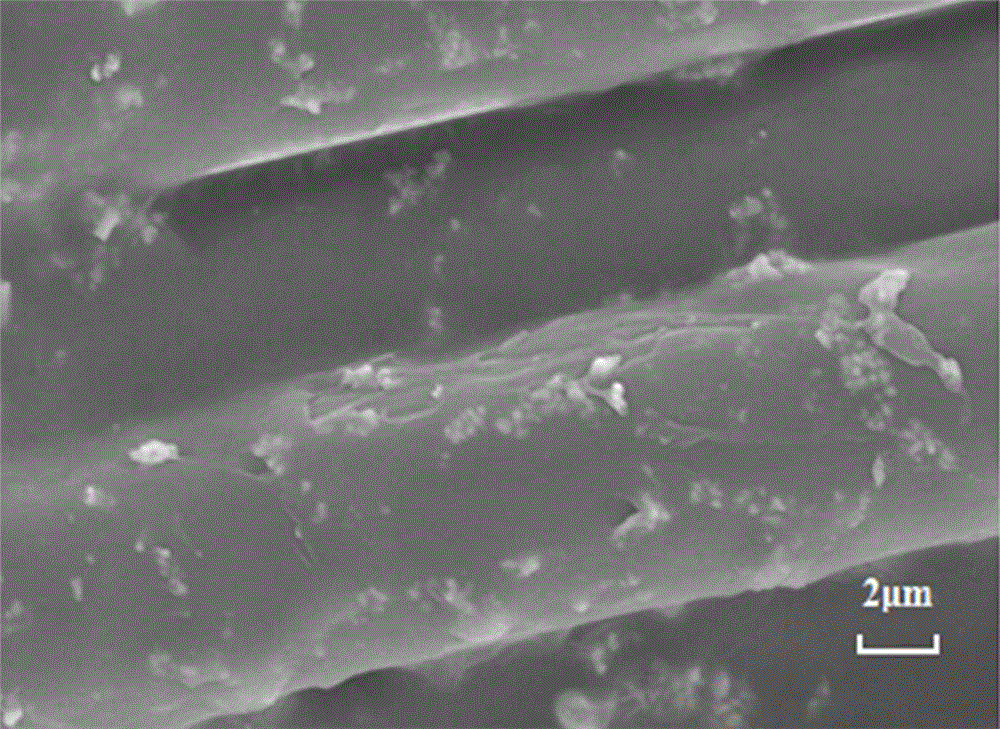

[0039] 1) Mix ethanol and water uniformly at 9:1 (volume ratio), add acetic acid dropwise to the mixed solution, adjust the pH value to 6, add quantitative KH-550, prepare a solution with a KH550 content of 1 wt%, and make The solution was hydrolyzed at 25°C for 90 minutes; then 1um and 3nm Al were added to the solution 2 o 3 , magnetically stirred at 25°C for 90 minutes, suction filtered, dried, ground, and sieved before use.

[0040] 2) The modified 1um and 3nm Al 2 o 3 Add it into distilled water according to the mass ratio of 3:1, ultrasonically disperse it for 15 minutes, and then spray it evenly on the surface of carbon fiber cloth, and control the surface density of the particles to 5g / m 2 ; Dry the sprayed fiber cloth at 110°C for 5 minutes and then cool to room temperature.

[0041] 3) Clean the mold, apply the release agent and lay t...

Embodiment 2

[0045] A method for preparing a multi-scale micro-nano particle interlayer toughened composite material, the steps of which are:

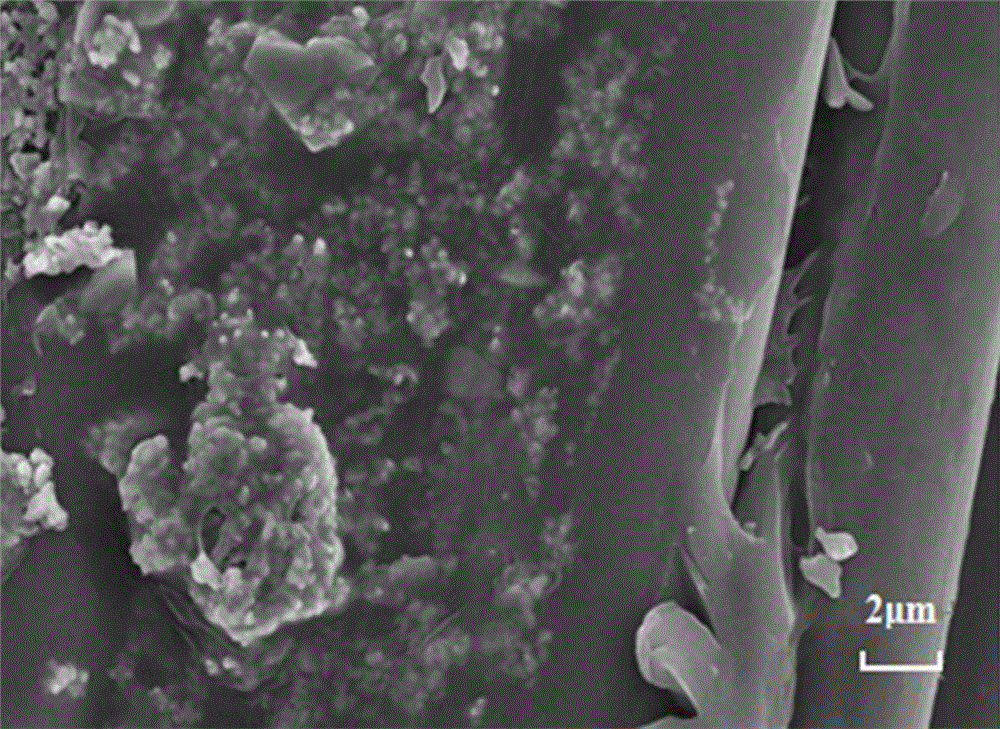

[0046] 1) Mix ethanol and water evenly at a ratio of 1:9 (volume ratio), add acetic acid dropwise to the mixed solution, adjust the pH value to 1, add a quantitative amount of coupling agent KH-560, and prepare a solution with a KH560 content of 15wt% , and the solution was hydrolyzed at 90°C for 10 minutes; then 30um and 30nm Al were added to the solution 2 o 3 , magnetically stirred at 70° C. for 10 min, suction filtered, dried, ground, and sieved before use.

[0047] 2) The modified 30um and 30nm Al 2 o 3 , added to distilled water according to the mass ratio of 1:3, ultrasonically dispersed for 90 minutes, and then evenly sprayed on the surface of carbon fiber cloth, and the surface density of the particles was controlled to be 50g / m 2 ; Dry the sprayed fiber cloth at 25°C for 2h and then cool to room temperature.

[0048] 3) Clean the mol...

Embodiment 3

[0050] A method for preparing a multi-scale micro-nano particle interlayer toughened composite material, the steps of which are:

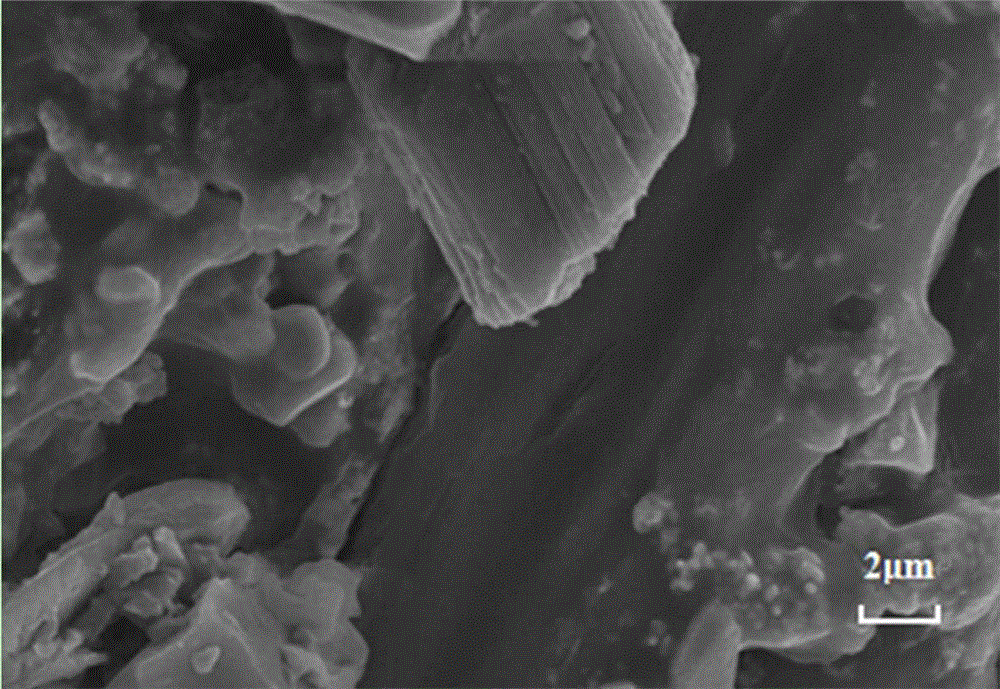

[0051] 1) Mix ethanol and water evenly at 8:2 (volume ratio), add acetic acid dropwise to the mixed solution, adjust the pH value to 3, add quantitative coupling agent KH-560, and prepare a solution with a KH560 content of 10wt%. , and the solution was hydrolyzed at 45°C for 50min; then 10um and 10nm Al were added to the solution 2 o 3 , magnetically stirred at 45° C. for 50 min, suction filtered, dried, ground, and sieved before use.

[0052] 2) The modified 10um and 10nm Al 2 o 3 Add it into distilled water at a mass ratio of 1:1, ultrasonically disperse it for 60 minutes, and then spray it evenly on the surface of carbon fiber cloth to control the surface density of the particles to 15g / m 2 ; Dry the sprayed fiber cloth at 60°C for 1 hour and then cool to room temperature.

[0053] 3) Clean the mold, apply the release agent and lay the laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com