High-capacity graphene/ silicone composite negative electrode material and preparation method

A negative electrode material, graphene technology, applied to battery electrodes, electrical components, circuits, etc., can solve the problems of not being able to effectively hinder silicon expansion, not being able to effectively improve silicon conductivity, and poor battery cycle stability. Industrial application, improving cycle performance and battery rate, improving the effect of coating ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

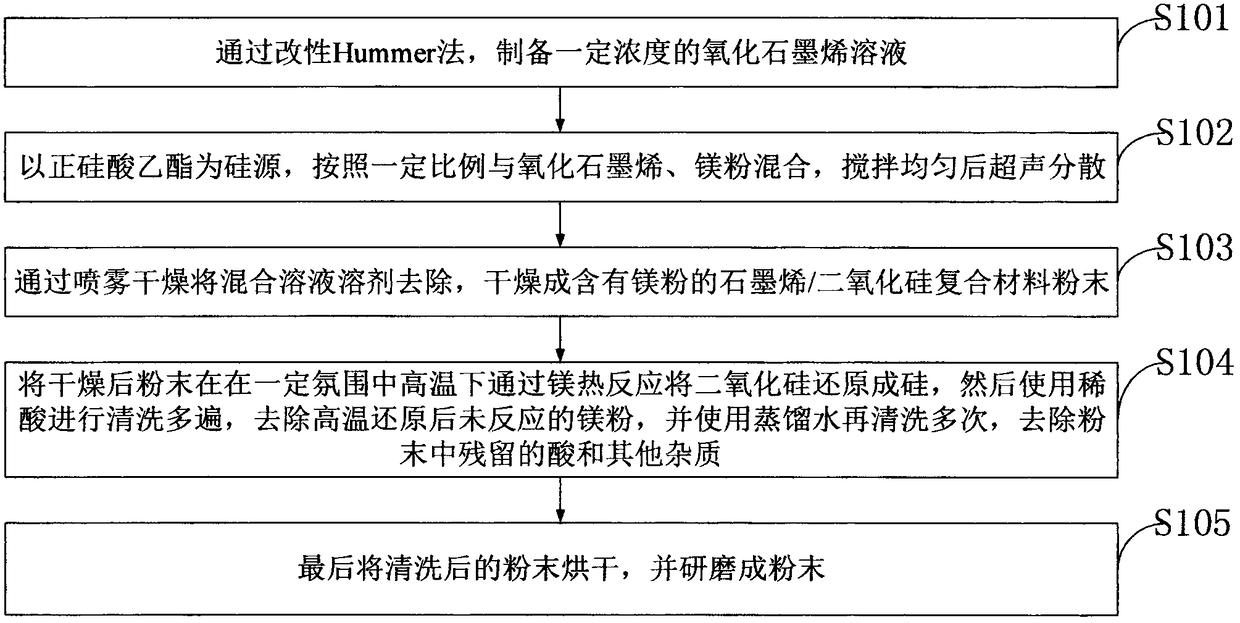

[0045] Such as figure 1As shown, the preparation method of the high-capacity graphene / silicon composite negative electrode material provided by the embodiment of the present invention includes:

[0046] S101: Prepare a graphene oxide solution with a certain concentration by modifying the Hummer method;

[0047] S102: Use ethyl orthosilicate as the silicon source, mix with graphene oxide and magnesium powder in a certain proportion, stir evenly and then ultrasonically disperse;

[0048] S103: removing the solvent from the mixed solution by spray drying, and drying it into a graphene / silicon dioxide composite material powder containing magnesium powder;

[0049] S104: The dried powder is reduced to silicon by magnesia thermal reaction at high temperature in a certain atmosphere, and then washed several times with dilute acid to remove unreacted magnesium powder after high temperature reduction, and then washed with distilled water for several times Second, remove residual acid...

Embodiment example 1

[0070] (1) Prepare a certain 1% graphene oxide ethanol solution by modifying the Hummer method, the graphene oxide sheet diameter is 5-10um, and the thickness is 1-3nm;

[0071] (2) Using ethyl orthosilicate as the silicon source, get 10 g of ethyl orthosilicate, 100 g of graphene oxide ethanol solution, and 20 g of particle diameter of 10 μm magnesium powder are evenly mixed, stirred for 20 minutes, ultrasonic for 30 minutes, and the ultrasonic power is 500 W; ( 3) Remove the mixed solution solvent by spray drying, the spray drying inlet temperature is 120°C, the outlet temperature is 80°C, and dried into graphene / silicon dioxide composite material powder containing magnesium powder;

[0072] (4) Put the dried powder in a nitrogen atmosphere containing 3% hydrogen, reduce silicon dioxide to silicon by magnesia thermal reaction at a high temperature of 600°C, and then wash it with 3% dilute hydrochloric acid for 20 minutes to remove the untreated particles after high temperatur...

Embodiment example 2

[0075] (1) By modifying the Hummer method, prepare 1.5% graphene oxide ethanol: a mixed solvent solution with a volume ratio of deionized water of 9:1, graphene oxide sheet diameter 2-5um, thickness 1-3nm;

[0076] (2) Using ethyl orthosilicate as the silicon source, take 20 g of ethyl orthosilicate, 200 g of graphene oxide ethanol solution, and 40 g of magnesium powder with a particle size of 10 um, mix evenly, stir for 30 minutes, and ultrasonic for 40 minutes, with an ultrasonic power of 400 W;

[0077] (3) The mixed solution solvent is removed by spray drying, the spray drying inlet temperature is 110°C, and the outlet temperature is 80°C, and dried into graphene / silicon dioxide composite material powder containing magnesium powder;

[0078] (4) Put the dried powder in a nitrogen atmosphere containing 4% hydrogen, reduce silicon dioxide to silicon by magnesia thermal reaction at a high temperature of 600°C, and then use a mass fraction of 2% dilute sulfuric acid to wash for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com