Silicon-based negative electrode material and method thereof

A silicon-based negative electrode material, nano-silicon technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of small selection of carbon-silicon negative electrode materials and single preparation methods, so as to avoid thickening and increase capacity and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

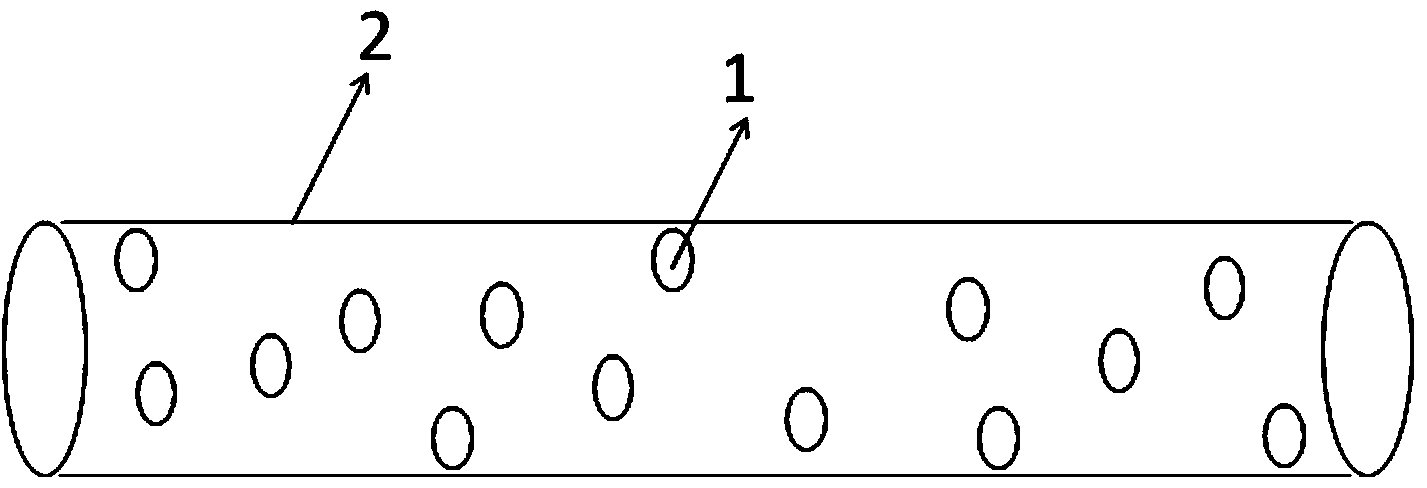

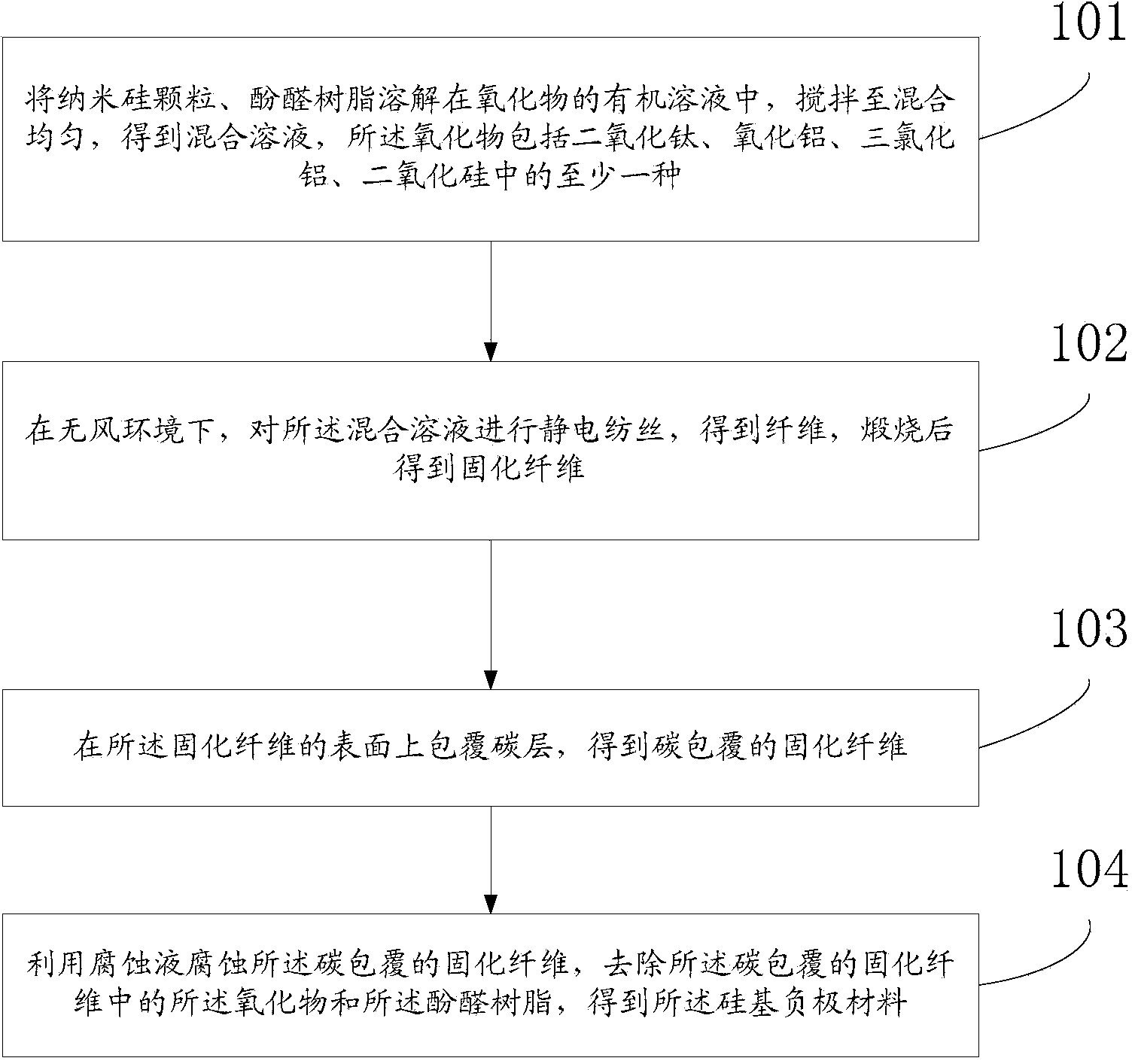

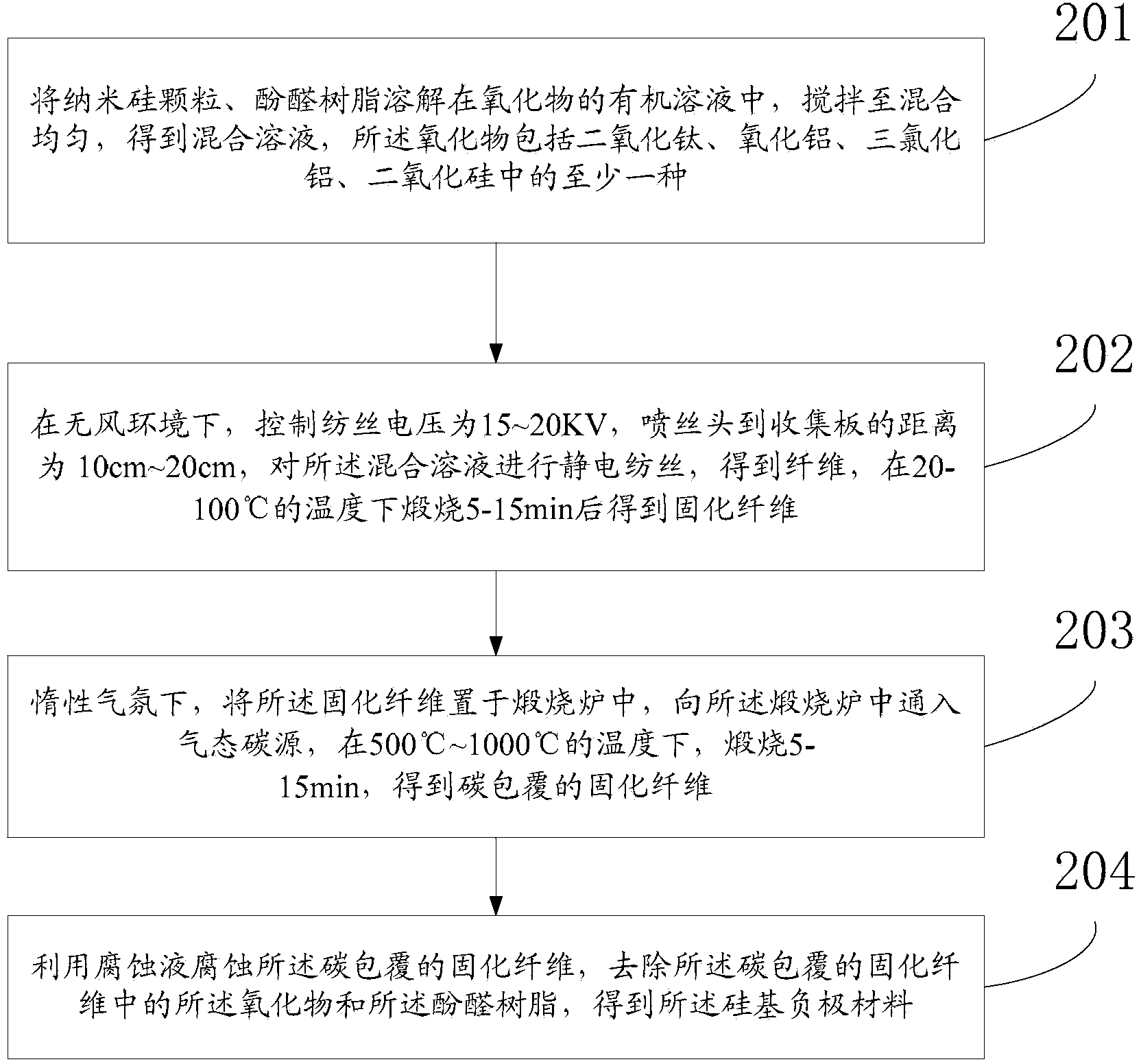

[0046] In the third aspect, the embodiment of the present invention provides a method for preparing a silicon-based negative electrode material, with figure 2 For the preparation flow chart of this method, as attached figure 2 As shown, the method includes:

[0047] Step 101, dissolving nano-silicon particles and phenolic resin in an organic solution of oxides, stirring until uniformly mixed to obtain a mixed solution, the oxides including at least one of titanium dioxide, aluminum oxide, aluminum trichloride, and silicon dioxide kind.

[0048] Wherein, in step 101, the organic solution must be a solvent for both the phenolic resin and the above-mentioned oxides, so that the nano-silicon particles form a uniform dispersion system therein.

[0049] The above-mentioned organic solution in titanium dioxide, aluminum oxide, aluminum trichloride, and silicon dioxide can be obtained by performing a hydrolysis reaction in an organic solvent using a titanium compound, an aluminum co...

Embodiment 1

[0071] 1) Mix 1ml of tetrabutyl titanate with 9g of ethanol and stir for 2h to obtain a titanium dioxide solution. 0.1 g of nano-silicon particles were added to the titanium dioxide solution, and 1.0 g of phenolic resin was added at the same time, and stirred at 70° C. for 1 h to obtain a mixed solution.

[0072] 2) The above mixed solution was drawn into filamentous fibers by electrospinning, and dried at 50° C. for 10 minutes to obtain cured fibers.

[0073] 3) Under an inert gas environment, place the solidified fiber in a calciner, and at the same time pass methane into the calciner, calcinate at a temperature of 850° C. for 10 minutes, and then cool to room temperature to obtain a carbon-coated cured fiber .

[0074] 4) At normal temperature, the carbon-coated solidified fiber is corroded by hydrofluoric acid with a mass fraction of 10%, to remove titanium dioxide and phenolic resin therein, and obtain the desired silicon-based negative electrode material of the present ...

Embodiment 2

[0076] 1) Mix 1.2ml of isopropyl titanate with 9g of ethanol and stir for 2 hours to obtain a titanium dioxide solution. 0.1 g of nano-silicon particles were added to the titanium dioxide solution, and 1.0 g of phenolic resin was added at the same time, and stirred at 70° C. for 1 h to obtain a mixed solution.

[0077] 2) The above mixed solution was drawn into filamentous fibers by electrospinning, and dried at 20° C. for 15 minutes to obtain cured fibers.

[0078] 3) Under an inert gas environment, place the solidified fiber in a calciner, and at the same time pass toluene into the calciner, calcinate at a temperature of 500 ° C for 15 minutes, and then cool to room temperature to obtain a carbon-coated cured fiber .

[0079] 4) At normal temperature, the carbon-coated solidified fiber is corroded by hydrofluoric acid with a mass fraction of 10%, to remove titanium dioxide and phenolic resin therein, and obtain the desired silicon-based negative electrode material of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com