A preparation method of uniform and ordered platinum cube or polyhedron nanoparticle array

A nanoparticle array and nanoparticle technology, which is applied in the direction of nanotechnology, can solve the problems of single particle shape, difficulty in contacting precursors with end-capping agents, and difficulty in realizing other shapes and types, achieving high repeatability, high repeatability, and high efficiency. The effect of adsorption capping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

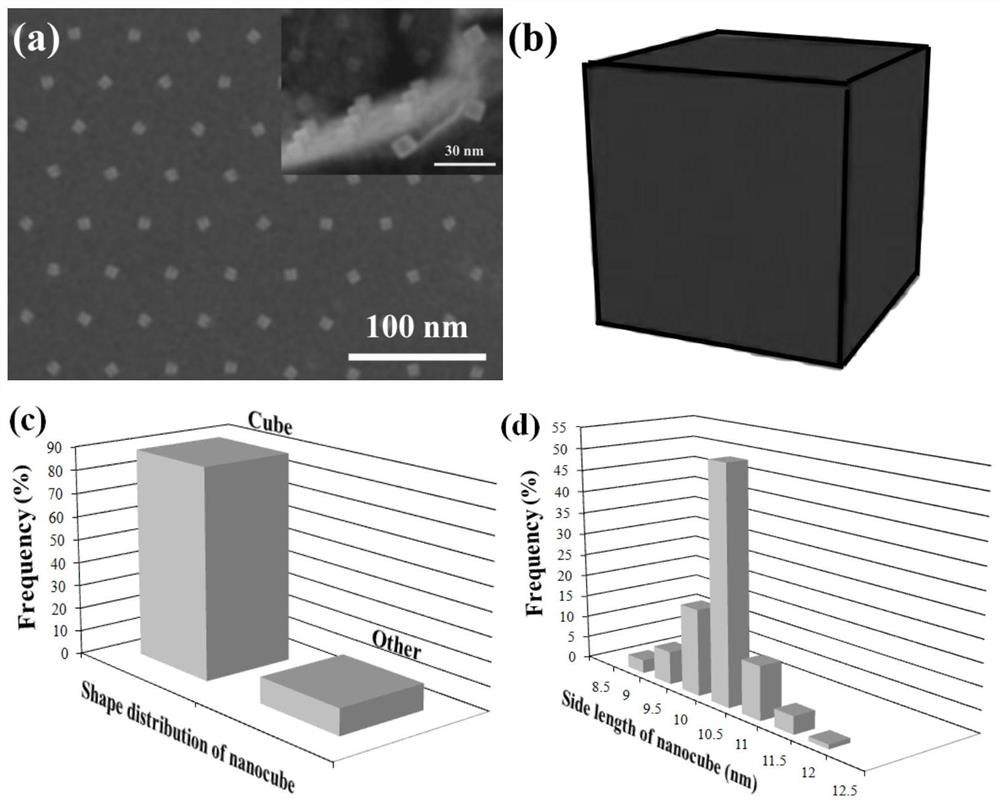

Embodiment 1

[0044] (1) Prepare the carrier loaded with hole array template by diblock copolymer template method

[0045] Add pyridine to the tetrahydrofuran organic solution to a concentration of 5.1 mM·L -1 The polystyrene-block-polyvinylpyridine (PS(27000)-b-P4VP(17000)) block copolymer, sealed, stirred on a magnetic stirrer at a speed of 400rpm at 50°C until the solution was transparent, and obtained An organic solution that self-assembles into spherical micelles with a polystyrene shell / polyvinylpyridine core structure.

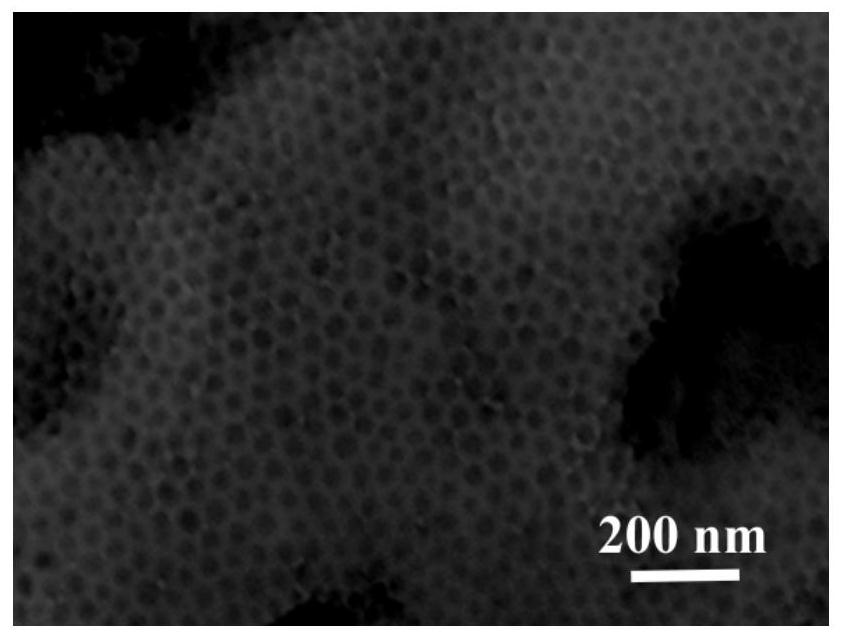

[0046] The carbon paper with a size of 10mm*10mm and a thickness of 0.2mm is purged with high-purity nitrogen for 5 minutes, and placed on a spin coater as a carrier. After dropping 0.2mL organic solution of self-assembled spherical micelles with polystyrene shell / polyvinylpyridine core structure on the surface of carbon paper, first homogenize at room temperature at 1000rpm for 5s, and then at 4000rpm Uniform 60s. After the spin-coated sample was left standing in...

Embodiment 2

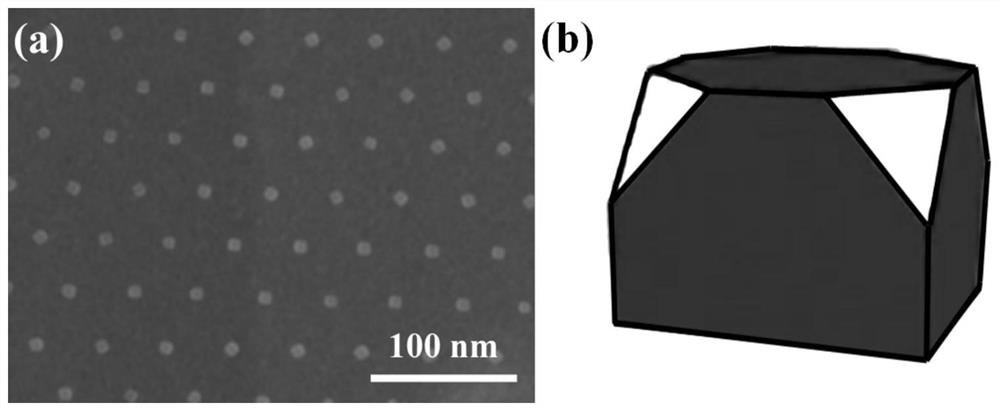

[0052] Referring to Example 1, the only difference is that in step (2) in the chloroplatinic acid aqueous solution containing the hydrochloric acid capping agent, the mass ratio of hydrochloric acid to chloroplatinic acid is 0.18, and in the final uniform and ordered array of platinum nanoparticles, the particles are meso A polyhedron between a hemisphere and a cube. image 3 (a) and (b) respectively show the topography photos of the obtained polyhedral platinum nanoparticle array and the approximate shape of the particles, where the gray surface represents the Pt(100) crystal plane, and the white region represents Pt(100) and Pt(111) composed of steps.

Embodiment 3

[0054] Referring to Example 1, the only difference is that in step (2) in the chloroplatinic acid aqueous solution containing the hydrochloric acid capping agent, the mass ratio of hydrochloric acid to chloroplatinic acid is 0.1, and in the final uniform and ordered array of platinum nanoparticles, the particles are between A polyhedron between a hemisphere and a cube. Figure 4 (a) and (b) respectively show the topography photos of the obtained polyhedral platinum nanoparticle array and the approximate shape of the particles, where the gray surface represents the Pt(100) crystal plane, and the white region represents Pt(100) and Pt(111) composed of steps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com